-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 13, 2025 10:45 Back to list

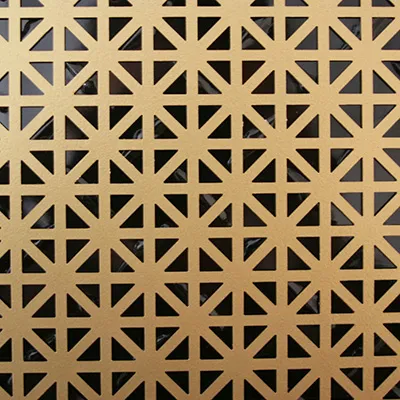

custom square wire mesh

Custom square wire mesh, often overlooked amidst more conventional materials, stands as a cornerstone in various industrial applications, showcasing an impressive blend of adaptability, robustness, and precision. With a heritage rooted deep in manufacturing and architectural craftsmanship, this versatile material is indispensable for those who prioritize quality and durability.

Furthermore, custom square wire mesh is integral in sustainable building practices. Its recyclability and the sustainable sourcing of raw materials align with global environmental goals. As sustainability becomes a non-negotiable element of modern construction, materials like square wire mesh that harmonize with eco-friendly objectives gain an edge. Professionals committed to reducing their carbon footprint will find this mesh a viable option due to its low impact on the environment and contribution to LEED certifications. A testament to the reliability of custom square wire mesh is its application in critical infrastructure projects around the globe. From bridges to airports, its implementation guarantees not only safety and strength but also compliance with international engineering standards. This aspect underlines its authoritativeness and trustworthiness in industries where precision and safety are non-negotiable. Selecting the right custom square wire mesh begins with partnering with experienced manufacturers who uphold rigorous quality control measures. These specialists employ cutting-edge technology to ensure each roll of mesh meets the highest standards. By conducting meticulous testing and quality checks, they provide products that professionals can trust implicitly. In conclusion, custom square wire mesh offers a versatile, durable, and precise solution for various industries. Its unique characteristics support critical applications in both industrial and architectural contexts. Specialists and professionals who demand the highest levels of quality and dependability rely on it to deliver optimal performance. It stands as a testament to how combining traditional craftsmanship with modern technology can yield materials that address contemporary needs while adhering to stringent industry standards. As businesses continually seek innovative solutions, custom square wire mesh proves to be an indispensable resource in achieving operational excellence and design innovation.

Furthermore, custom square wire mesh is integral in sustainable building practices. Its recyclability and the sustainable sourcing of raw materials align with global environmental goals. As sustainability becomes a non-negotiable element of modern construction, materials like square wire mesh that harmonize with eco-friendly objectives gain an edge. Professionals committed to reducing their carbon footprint will find this mesh a viable option due to its low impact on the environment and contribution to LEED certifications. A testament to the reliability of custom square wire mesh is its application in critical infrastructure projects around the globe. From bridges to airports, its implementation guarantees not only safety and strength but also compliance with international engineering standards. This aspect underlines its authoritativeness and trustworthiness in industries where precision and safety are non-negotiable. Selecting the right custom square wire mesh begins with partnering with experienced manufacturers who uphold rigorous quality control measures. These specialists employ cutting-edge technology to ensure each roll of mesh meets the highest standards. By conducting meticulous testing and quality checks, they provide products that professionals can trust implicitly. In conclusion, custom square wire mesh offers a versatile, durable, and precise solution for various industries. Its unique characteristics support critical applications in both industrial and architectural contexts. Specialists and professionals who demand the highest levels of quality and dependability rely on it to deliver optimal performance. It stands as a testament to how combining traditional craftsmanship with modern technology can yield materials that address contemporary needs while adhering to stringent industry standards. As businesses continually seek innovative solutions, custom square wire mesh proves to be an indispensable resource in achieving operational excellence and design innovation.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025