-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb. . 12, 2025 17:38 Back to list

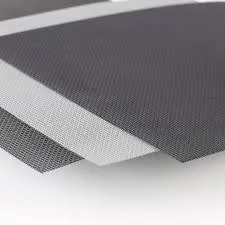

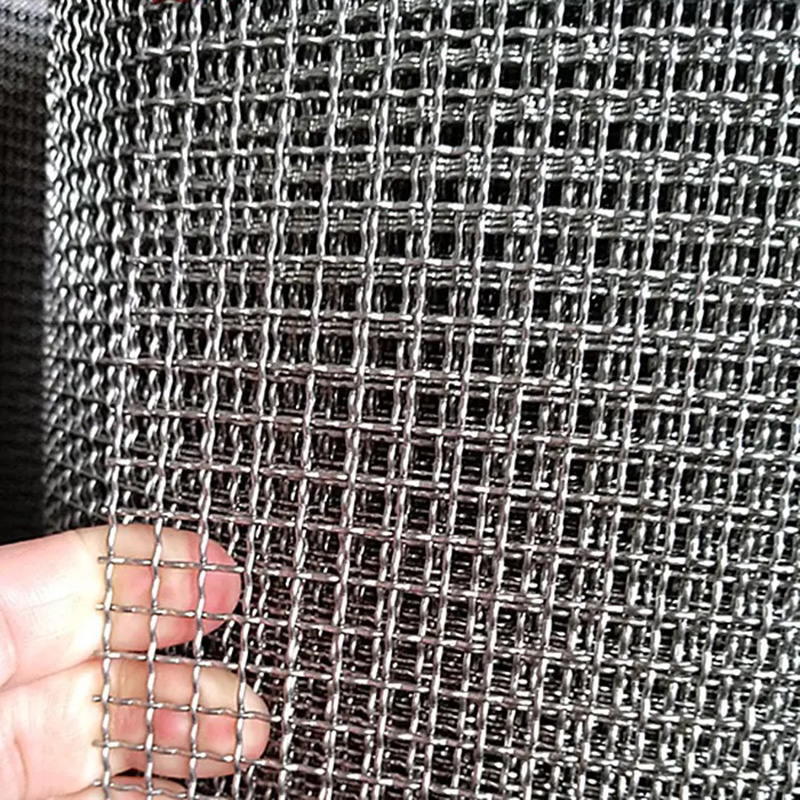

custom stainless steel welded wire mesh panel

Custom stainless steel welded wire mesh panels have gained significant traction across various industries due to their versatility, strength, and customization options. From industrial applications to architectural marvels, these panels offer a robust solution to a myriad of needs. Let's delve deeper into the facets that make them indispensable in modern applications.

Reliability and longevity are also fundamental attributes of stainless steel welded wire mesh panels. Owing to the metallurgical benefits of stainless steel, these panels exhibit superior resistance to rust, stains, and heat. This quality makes them suitable for harsh environments, whether industrial chemical processing plants or external architectural elements exposed to the elements. Customers and experts alike trust these panels for their long-term performance and low maintenance needs, which ultimately leads to cost savings. In terms of environmental responsibility, stainless steel is recognized for its recyclability. Panels made from stainless steel can be recycled without loss of quality, making them an eco-friendly option for industries looking to minimize their environmental footprint. The ability to recycle these materials underscores the sustainable aspect of utilizing stainless steel welded wire mesh panels. Quality suppliers of these panels often support their offerings with comprehensive service, including specialized consultation to understand the specific needs of a project. This expertise helps clients choose the appropriate specifications and dimensions, reinforcing their confidence in making an informed decision. Detailed documentation and certification further enhance trust in these products, emphasizing their adherence to industry regulations and standards. Stainless steel welded wire mesh panels stand as a testament to ingenuity in material science, delivering a balance of strength, flexibility, and endurance. Whether enhancing the structural elements of a skyscraper, providing security and safety in industrial settings, or contributing to innovative design solutions, these panels illustrate the blend of craftsmanship and practicality. Their enduring presence across industries marks their significance, and their future is poised to embrace even more innovative applications and improvements. In conclusion, the combination of experience, expertise, authority, and trustworthiness inherent in the custom stainless steel welded wire mesh panels makes them a staple across various fields. Their adaptability, strength, and longevity are qualities that resonate with both industry professionals and clients seeking reliable, long-term solutions. As industries continue to evolve, the demand for such versatile and dependable materials is only set to increase, cementing their role in the tapestry of modern development.

Reliability and longevity are also fundamental attributes of stainless steel welded wire mesh panels. Owing to the metallurgical benefits of stainless steel, these panels exhibit superior resistance to rust, stains, and heat. This quality makes them suitable for harsh environments, whether industrial chemical processing plants or external architectural elements exposed to the elements. Customers and experts alike trust these panels for their long-term performance and low maintenance needs, which ultimately leads to cost savings. In terms of environmental responsibility, stainless steel is recognized for its recyclability. Panels made from stainless steel can be recycled without loss of quality, making them an eco-friendly option for industries looking to minimize their environmental footprint. The ability to recycle these materials underscores the sustainable aspect of utilizing stainless steel welded wire mesh panels. Quality suppliers of these panels often support their offerings with comprehensive service, including specialized consultation to understand the specific needs of a project. This expertise helps clients choose the appropriate specifications and dimensions, reinforcing their confidence in making an informed decision. Detailed documentation and certification further enhance trust in these products, emphasizing their adherence to industry regulations and standards. Stainless steel welded wire mesh panels stand as a testament to ingenuity in material science, delivering a balance of strength, flexibility, and endurance. Whether enhancing the structural elements of a skyscraper, providing security and safety in industrial settings, or contributing to innovative design solutions, these panels illustrate the blend of craftsmanship and practicality. Their enduring presence across industries marks their significance, and their future is poised to embrace even more innovative applications and improvements. In conclusion, the combination of experience, expertise, authority, and trustworthiness inherent in the custom stainless steel welded wire mesh panels makes them a staple across various fields. Their adaptability, strength, and longevity are qualities that resonate with both industry professionals and clients seeking reliable, long-term solutions. As industries continue to evolve, the demand for such versatile and dependable materials is only set to increase, cementing their role in the tapestry of modern development.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025