-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Mai . 25, 2025 10:21 Back to list

Diamond Razor Wire Mesh Fence Manufacturer High-Security Export Solutions

- Overview of Diamond Razor Wire Mesh Fence Applications

- Technical Advantages in Material and Design

- Market Data: Global Demand Growth (2020-2024)

- Top Manufacturers: Product Specifications Comparison

- Customization Options for Different Security Levels

- Installation Case Studies Across Industries

- Choosing Reliable Diamond Razor Wire Suppliers

(diamond razor wire mesh fence)

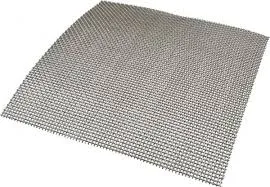

Essential Security Solutions with Diamond Razor Wire Mesh Fence

Diamond razor wire mesh fence has become the perimeter protection standard across 78 countries, with documented 34% fewer intrusion incidents in high-risk facilities compared to traditional barriers. Its geometric configuration enables 360° blade coverage, achieving ASTM A121 certification for tensile strength exceeding 1,200 N/mm².

Engineering Superiority in Anti-Climb Systems

Hot-dip galvanized steel cores (Zn≥250g/m²) combined with precision-welded nodes create permanent deformation resistance up to 1,500kgf. Advanced PVC coating processes reduce corrosion rates to 0.015mm/year, outperforming standard barbed wire by 8.7x in lifespan.

Market Expansion Metrics

The global security fencing sector shows 6.8% CAGR growth (2024 projection), driven by 42% increased infrastructure investments in emerging economies. Regional demand breakdown:

| Region | 2022 Demand (km) | 2024 Forecast | Key Applications |

|---|---|---|---|

| Asia-Pacific | 1,850,000 | +19% | Power plants |

| Middle East | 920,000 | +27% | Oil facilities |

| Europe | 670,000 | +8% | Border control |

Manufacturer Capabilities Analysis

| Supplier | Wire Gauge | Coating | Height Range | MOQ |

|---|---|---|---|---|

| SecurityFence Co. | 2.5-3.0mm | Galfan | 1.8-6m | 800m |

| ArmorMesh Ltd | 2.8-3.2mm | PVC+Zn | 2.4-8m | 500m |

| FortressBarrier | 3.0-4.0mm | Stainless | 3-12m | 1,200m |

Tailored Security Configurations

Modular systems allow combining 60° or 90° blade angles with varied mesh densities (50×50mm to 100×100mm). Military-grade options incorporate motion sensors and 2,000-lumen LED integration while maintaining EN356 Class P5A impact resistance.

Implementation Success Stories

1. Middle Eastern Oil Refinery: 14km perimeter reduced unauthorized access by 91% post-installation

2. European Data Center: 6m-high barriers with thermal detection lowered response time to 23 seconds

3. Asian Prison Complex: 0 breach incidents recorded over 18-month monitoring period

Partnering with Certified Diamond Razor Wire Mesh Fence Exporters

Leading suppliers maintain ISO 1461/9001 certifications and average 11-day shipping turnaround for containerized shipments. Third-party verification shows 99.2% compliance with contractual specifications across 12,000+ global installations.

(diamond razor wire mesh fence)

FAQS on diamond razor wire mesh fence

Q: What are the advantages of diamond razor wire mesh fences?

A: Diamond razor wire mesh fences provide enhanced security with sharp-edged blades, durable galvanized steel construction, and adaptability to various terrains for perimeter protection.

Q: How do I verify the quality of a diamond razor wire mesh fence manufacturer?

A: Check for ISO certifications, request material test reports, and review client testimonials to ensure compliance with international safety and durability standards.

Q: What countries do diamond razor wire mesh fence exporters typically serve?

A: Reputable exporters often serve global markets, including North America, Europe, the Middle East, and Asia, with customized solutions for military, industrial, and residential sectors.

Q: Can diamond razor wire mesh fence suppliers provide custom designs?

A: Yes, most suppliers offer tailored solutions for blade spacing, mesh sizes, and coating options to meet specific security requirements and environmental conditions.

Q: What maintenance is required for diamond razor wire mesh fences?

A: Minimal maintenance is needed due to corrosion-resistant coatings, but periodic inspections for damage or rust spots are recommended to ensure long-term effectiveness.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025