-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 18, 2025 01:20 Back to list

Durable & Stylish Roof Tiles for Lasting Home Protection

Navigating the Landscape of Advanced Roofing Solutions: Industry Trends and Innovations

The global construction sector is undergoing a profound transformation, driven by an increasing demand for sustainable, resilient, and energy-efficient building materials. In this dynamic environment, high-performance roofing solutions are paramount, serving not merely as protective barriers but as integral components of a building's overall thermal envelope and structural integrity. Among the myriad options available, Roof Tiles stand out as a versatile and enduring choice, continuously evolving to meet the rigorous demands of modern B2B applications. Current industry trends highlight a shift towards advanced composite materials, enhanced fire resistance, superior wind uplift performance, and sophisticated interlocking designs that facilitate rapid installation while minimizing waste. Furthermore, the integration of reflective coatings and photovoltaic readiness is becoming standard, pushing roofing systems beyond basic weatherproofing to active energy management solutions. Stakeholders in industrial, commercial, and agricultural sectors are increasingly prioritizing long-term value, assessing materials based on their total cost of ownership, which encompasses initial investment, maintenance requirements, and anticipated service life. This comprehensive evaluation underscores the importance of selecting roofing materials that promise not just immediate cost-effectiveness but sustained performance and adaptability to future sustainability mandates. The emphasis on robust manufacturing processes and adherence to international quality standards, such as ISO 9001 and ASTM, are critical differentiators, ensuring that these products deliver consistent quality and predictable performance in diverse climatic conditions. Our commitment to these principles ensures that our roofing solutions are at the forefront of innovation, providing unparalleled durability, aesthetic appeal, and environmental responsibility for large-scale projects.

Precision Engineering: The Manufacturing Process and Technical Advantages of Roof Tiles

The superior performance of Roof Tiles is rooted in a meticulously controlled manufacturing process that transforms raw materials into highly durable, precision-engineered roofing components. Typically, the primary materials involve high-grade steel or aluminum, chosen for their inherent strength-to-weight ratio and corrosion resistance. The journey begins with the selection of premium coils, which then undergo rigorous preparation, including cleaning and pre-treatment to ensure optimal adhesion of subsequent coatings. A critical phase is the application of multi-layer protective coatings, often starting with a zinc or zinc-aluminum galvanization process for exceptional anti-corrosion properties, followed by primer layers and high-performance paint systems. These paint systems are specifically formulated for exterior exposure, offering superior UV resistance, color retention, and chalking resistance, crucial for maintaining aesthetic integrity over decades. Precision roll-forming or stamping machinery then shapes the coated metal into the specific profiles of the Roof Tiles, ensuring dimensional accuracy and consistency across every piece. Advanced CNC machining is employed where intricate detailing or custom cuts are required, guaranteeing seamless interlocks and precise fits on complex roof structures. Each batch undergoes stringent quality control inspections, adhering to international standards such as ISO 9001 for quality management systems and ANSI/SPRI ES-1 for wind uplift resistance, particularly for edge and corner conditions. Our products are designed for an extended service life, typically exceeding 50 years under normal conditions, offering a significant reduction in lifecycle costs compared to conventional roofing materials. The inherent properties of these engineered tiles provide substantial advantages in demanding B2B environments, including enhanced energy efficiency through reflective surfaces that reduce solar heat gain, superior resistance to extreme weather events, and excellent fire ratings, often Class A, crucial for industrial and commercial safety standards. Their lightweight nature simplifies structural requirements and accelerates installation, translating to tangible cost and time savings on large-scale projects.

Figure 1: Illustration of a typical manufacturing process for metal Roof Tiles, highlighting the precision and multi-layered protection applied.

Technical Specifications and Performance Metrics of Advanced Roof Tiles

Understanding the detailed technical specifications of Roof Tiles is crucial for B2B decision-makers to ensure optimal material selection for their specific project requirements. These specifications directly correlate to the product's performance, durability, and compliance with building codes and environmental regulations. Key parameters often include material composition, which dictates strength and longevity; coating type and thickness, directly impacting corrosion resistance and aesthetic life; and specific physical properties such as weight per square meter, crucial for structural load calculations. Fire rating, typically assessed by ASTM E108 or UL 790, indicates the material's resistance to external fire exposure, with Class A being the highest achievable standard, offering superior safety for commercial and industrial facilities. Wind uplift resistance, measured according to standards like ASTM D3161 or Florida Building Code protocols, determines the tile's ability to withstand high wind speeds and turbulent conditions, a critical factor in hurricane-prone regions. Thermal performance, often quantified by Solar Reflectance Index (SRI), highlights the tile's capacity to reflect solar radiation and reduce heat absorption, contributing significantly to a building's energy efficiency and reducing cooling loads. Acoustic insulation properties, while less frequently highlighted, can also be a significant benefit in noisy industrial environments. Furthermore, resistance to hail impact (e.g., UL 2218 Class 4) and extreme temperatures ensures resilience across diverse climates. Our Roof Tiles are engineered to exceed industry benchmarks, providing not just compliance but a margin of safety and performance that translates into reduced operational costs and enhanced asset protection over the lifespan of the building. The data below illustrates typical specifications, highlighting our commitment to delivering superior performance.

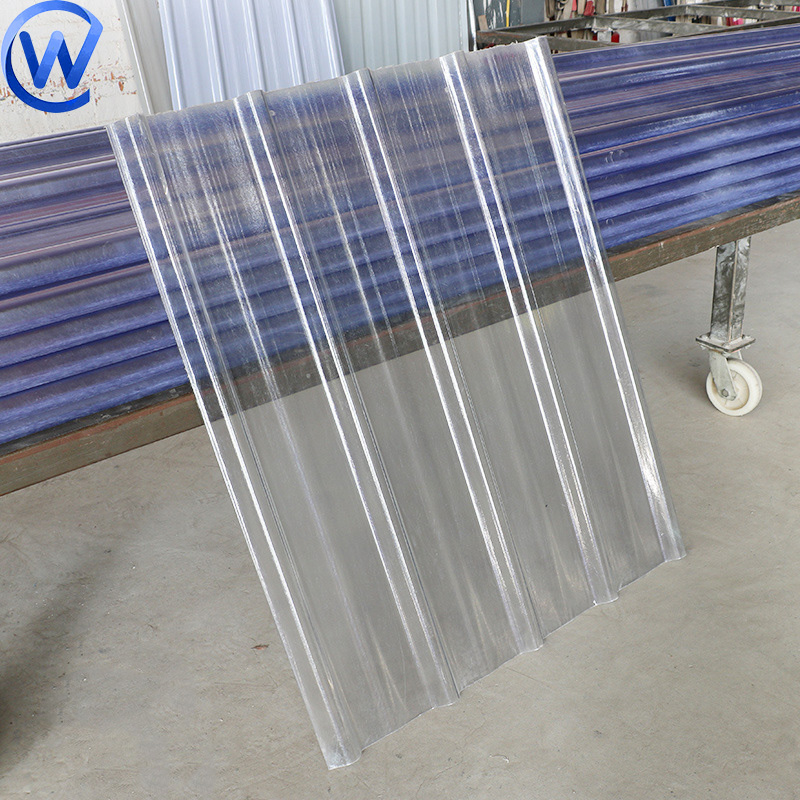

Figure 2: A visual representation of high-performance Roof Tiles, showcasing their robust design and material integrity.

| Parameter | Specification/Value | Standard/Certification |

|---|---|---|

| Base Material | Galvanized Steel (G90/AZ55) or Aluminum Alloy | ASTM A653 / ASTM B209 |

| Thickness Range | 0.4mm - 0.9mm (28-20 Gauge) | EN 10346 |

| Protective Coating | PVDF (Kynar 500) or SMP (Siliconized Modified Polyester) | ASTM A755 / A792, AAMA 2605 (for PVDF) |

| Fire Rating | Class A | ASTM E108 / UL 790 |

| Wind Uplift Resistance | Up to 180 MPH (3-second gust) | ASTM D3161, FBC (Florida Building Code) |

| Hail Impact Resistance | Class 4 | UL 2218 |

| Solar Reflectance Index (SRI) | White/Light Colors: 80+, Dark Colors: 30-50+ | ASTM E1980 |

| Weight per Sq. Meter | ~4.5 - 7.0 kg (depending on profile and gauge) | N/A (Calculated) |

| Operating Temperature Range | -40°C to +80°C | Manufacturer's Specification |

Diverse Applications and Real-World Success: Case Studies of Roof Tiles in Action

The adaptability and robust performance of Roof Tiles make them an ideal solution across a broad spectrum of B2B applications, ranging from large-scale industrial complexes to sophisticated commercial buildings and critical agricultural infrastructure. In industrial settings, such as manufacturing plants or logistics warehouses, the superior durability and resistance to harsh environmental factors, including chemical exposure and extreme temperatures, are invaluable. Their lightweight nature often facilitates easier installation over expansive areas, reducing construction timelines and labor costs. For commercial properties, including retail centers, office parks, and educational institutions, the aesthetic versatility of Roof Tiles, available in various profiles and colors, allows for seamless integration with architectural designs while providing long-term protection and energy efficiency benefits through reflective coatings. In the agricultural sector, where large span structures like barns, livestock shelters, and storage facilities require robust and low-maintenance roofing, these tiles offer excellent ventilation capabilities and resistance to corrosive animal waste by-products, ensuring a healthier environment and extended structural life. A compelling application example is a recent project for a major distribution center spanning over 500,000 square feet in a region prone to severe thunderstorms. The client required a roofing solution that could withstand sustained winds of 150 MPH, offer a Class A fire rating, and contribute to LEED certification. Our high-performance Roof Tiles, specifically designed for wind uplift resistance and equipped with advanced fire-retardant coatings, met all criteria, providing a durable, energy-efficient, and aesthetically pleasing roof that significantly lowered the building's operational costs and ensured business continuity during adverse weather events. Another case involved an agricultural cooperative needing to replace aging barn roofs; our solution provided not only superior weather protection but also improved thermal regulation within the barns, contributing to better animal welfare and reduced energy consumption for climate control. These real-world applications underscore the multifaceted advantages of our tailored roofing solutions.

Figure 3: An example of Roof Tiles installed on a commercial building, demonstrating superior aesthetics and durability.

Strategic Sourcing: Comparative Analysis and Tailored Solutions for Roof Tiles

When evaluating roofing materials for significant B2B investments, a thorough comparative analysis beyond initial purchase price is indispensable. While various roofing options exist—from traditional asphalt shingles to single-ply membranes (TPO/EPDM) and standing seam metal roofs—Roof Tiles offer a unique blend of durability, aesthetic appeal, and long-term cost-effectiveness. Asphalt shingles, though inexpensive upfront, have a significantly shorter lifespan (15-25 years) and are more susceptible to wind damage and UV degradation, leading to higher lifecycle costs through frequent replacement. Single-ply membranes are lightweight and offer excellent waterproofing but may lack the structural rigidity and aesthetic appeal suitable for certain high-visibility commercial or industrial projects, and their puncture resistance can be a concern. Standing seam metal roofs provide exceptional longevity and performance, similar to Roof Tiles, but their aesthetic is distinctly industrial, which may not align with all architectural visions, and installation can be more complex. Our Roof Tiles bridge this gap, offering the architectural elegance and dimensional stability often associated with traditional tiling, combined with the superior longevity, low maintenance, and high performance of advanced metal roofing systems. We distinguish ourselves not just through product quality but also through our comprehensive customization capabilities. For projects with unique structural requirements, specific aesthetic preferences, or stringent performance criteria, we offer tailored solutions. This includes custom color matching to corporate branding, specific tile profiles engineered for enhanced snow load or extreme wind conditions, and integration features for solar panel mounting or rainwater harvesting systems. Our design and engineering teams work collaboratively with clients from concept to completion, providing detailed technical drawings, performance simulations, and material recommendations to ensure the chosen Roof Tiles precisely meet the project's unique demands. This bespoke approach ensures that clients receive not just a product, but a complete roofing system optimized for their specific operational and environmental context, delivering maximum value and peace of mind.

Figure 4: Demonstrating the versatility of Roof Tiles in various profiles and finishes, enabling architectural customization.

| Feature | Roof Tiles (Metal/Composite) | Asphalt Shingles | Single-Ply Membranes (TPO/EPDM) |

|---|---|---|---|

| Lifespan (Years) | 50+ | 15-30 | 20-30 |

| Weight (per sq. ft.) | 1.0-1.5 lbs (lightweight) | 2.0-4.0 lbs (medium) | 0.3-0.5 lbs (very lightweight) |

| Wind Resistance | Excellent (up to 180 MPH) | Good (up to 110 MPH) | Very Good (up to 140 MPH) |

| Fire Rating | Class A | Class A or C | Class A, B, or C (varies) |

| Energy Efficiency (SRI) | High (reflective coatings) | Low to Moderate | Moderate to High (white membranes) |

| Maintenance | Low | Medium (granule loss, curling) | Low to Medium (seam integrity checks) |

| Aesthetic Versatility | High (many profiles & colors) | Medium (limited profiles) | Low (monolithic, industrial) |

| Environmental Impact | Recyclable, often made from recycled content | Landfill waste, oil-based | Less recyclable, petroleum-based |

Unwavering Commitment: Quality Assurance, Client Support, and Trustworthiness

At the core of our operations is an unwavering commitment to quality assurance and client satisfaction, embodying the highest standards of Authoritativeness and Trustworthiness in the B2B roofing sector. Our manufacturing facilities are ISO 9001:2015 certified, signifying a robust quality management system that governs every stage of production, from raw material procurement to final product inspection and packaging. This includes rigorous testing protocols for material composition, coating adhesion, dimensional accuracy, and performance under simulated environmental stressors, such as salt spray corrosion testing (ASTM B117), accelerated weathering (ASTM G154/G155), and cyclic wind resistance tests. Each batch of Roof Tiles is traceable through its unique production identifier, providing comprehensive data on its manufacturing history and quality control checkpoints. We are proud of our extensive service record, having successfully supplied roofing solutions for industrial and commercial projects for over two decades, building a reputation for reliability and excellence. Our long-standing partnerships with leading architectural firms, general contractors, and construction companies are a testament to our consistent product quality and dependable service. We stand by the durability of our products with comprehensive warranty programs, typically offering 30 to 50-year limited warranties on material performance and a separate warranty for coating integrity against chipping, peeling, or fading, providing long-term peace of mind for our B2B clients. Understanding the time-sensitive nature of large-scale construction projects, we maintain efficient logistics and supply chain management to ensure prompt delivery within agreed-upon schedules. Our typical lead time for standard products is 4-6 weeks, with expedited options available for urgent requirements. Our dedicated customer support team comprises technical experts who provide in-depth consultation, installation guidance, and post-sales support, ensuring that any inquiries or challenges are addressed swiftly and effectively. We believe that true partnership extends beyond the transaction, fostering relationships built on trust, transparency, and a shared commitment to project success.

Figure 5: Highlighting the robust quality control and testing procedures applied to Roof Tiles during manufacturing.

Frequently Asked Questions (FAQ) about Roof Tiles for B2B Clients

Q1: What is the typical lifespan of your Roof Tiles in commercial or industrial applications?

Our Roof Tiles are engineered for exceptional longevity. Depending on the specific material (e.g., galvanized steel with PVDF coating) and local environmental conditions, they typically come with a 50-year limited warranty and can last for 60 years or more with minimal maintenance. This significantly exceeds the lifespan of conventional roofing materials, offering superior long-term value.

Q2: How do your Roof Tiles contribute to a building's energy efficiency?

Many of our Roof Tiles are available with high-performance reflective coatings, particularly in lighter colors. These coatings are designed to reflect a significant portion of solar radiation, reducing heat absorption into the building. This lowers the cooling load on HVAC systems, leading to substantial energy savings and a reduced carbon footprint, aligning with green building initiatives and potentially qualifying for LEED points.

Q3: Are your Roof Tiles suitable for extreme weather conditions, such as high winds or heavy snow loads?

Absolutely. Our Roof Tiles are rigorously tested to meet and often exceed industry standards for extreme weather resilience. They feature robust interlocking designs and secure fastening systems that provide excellent wind uplift resistance, often rated for winds up to 180 MPH. For snow-prone regions, their structural integrity and smooth surfaces help shed snow efficiently, and specific profiles can be engineered to handle significant snow loads, minimizing the risk of structural damage.

Q4: What kind of warranty and customer support do you offer for large B2B projects?

We offer comprehensive warranty packages for our Roof Tiles, including up to a 50-year limited material warranty and a separate coating warranty covering against chipping, peeling, and fading for 30 years. Our dedicated B2B client support team provides extensive pre-sales consultation, technical assistance during installation, and responsive post-sales service. This includes project-specific documentation, on-site guidance if needed, and prompt resolution of any product-related inquiries to ensure your project's success.

Conclusion: Investing in Superior Roofing for Lasting Value

In the demanding realm of B2B construction, the choice of roofing material is a critical decision impacting long-term operational efficiency, safety, and asset value. Our advanced Roof Tiles represent the pinnacle of modern roofing technology, blending superior durability, energy efficiency, and aesthetic versatility with a commitment to stringent quality control and comprehensive customer support. From their meticulously engineered manufacturing processes to their proven performance in diverse and challenging application scenarios, these tiles offer a robust solution for industrial, commercial, and agricultural properties seeking to maximize their investment. By providing detailed technical specifications, transparent comparative analyses, and tailored customization options, we empower B2B decision-makers to select a roofing system that not only meets but exceeds their project requirements and sustainability goals. Investing in our Roof Tiles means choosing a solution that delivers not just protection, but a significant contribution to the overall efficiency and longevity of your building assets.

References

- American Society for Testing and Materials (ASTM) Standards for Roofing Materials.

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements.

- National Institute of Building Sciences (NIBS) Whole Building Design Guide for Sustainable Roofing.

- The Roof Consultant Institute (RCI, now IIBEC) Technical Bulletins on Metal Roofing Performance.

- Cool Roof Rating Council (CRRC) Product Performance Ratings.

This is the last article

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025

-

Find Your Perfect Fence: Durable, Secure, Affordable Solutions

NewsAug.16,2025

-

Custom Square Wire Mesh - High Quality, Wholesale Supply

NewsAug.15,2025

-

Custom & Wholesale Perforated Metal Mesh Sheets - Factory Direct

NewsAug.14,2025

-

Premium Rib Lath for Durable Stucco & Plaster Systems

NewsAug.13,2025