-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 02, 2024 07:15 Back to list

gabion wire mesh factories

The Importance and Role of Gabion Wire Mesh Factories in Modern Construction

Gabion wire mesh has become an essential material in modern civil engineering, landscaping, and erosion control. As a versatile solution, it plays a crucial role in a wide range of applications, from retaining walls to decorative facades. The growing demand for gabion structures has led to the establishment of specialized factories that produce high-quality gabion wire mesh, contributing significantly to various industries. This article explores the significance of gabion wire mesh factories, their production processes, and their impact on sustainable development.

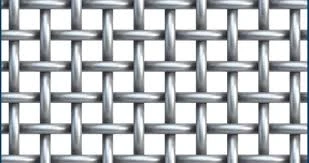

Gabion wire mesh is typically made from high-strength steel wire, coated with materials such as galvanization or PVC to enhance durability and resistance to environmental factors. These wires are assembled into cages or baskets, which can be filled with various materials, including stones, gravel, or even recycled materials. The flexibility of gabion structures allows them to adapt to different designs and applications, making them highly sought after in construction projects.

One of the primary functions of gabion wire mesh factories is to ensure the production of high-quality materials that meet industry standards. The manufacturing process involves several stages, including wire drawing, cleaning, coating, and weaving. Each step is crucial in ensuring that the final product is strong, durable, and suitable for the intended application. Advanced technology and high-quality materials are essential in this process, as the longevity and performance of the gabion structures heavily depend on the mesh used.

gabion wire mesh factories

Moreover, gabion wire mesh factories play a vital role in promoting sustainable development. Traditional construction materials, such as concrete and bricks, often have significant environmental footprints due to production processes and resource extraction. In contrast, gabions provide a more eco-friendly alternative. The ability to use natural stones or recycled materials as infill reduces the environmental impact, while the longevity of gabion structures minimizes the need for frequent repairs or replacements. This aligns with the growing trend of green building practices and the emphasis on sustainability in construction.

Additionally, gabion wire mesh factories can boost local economies by providing jobs and supporting local industries. The production of gabion wire mesh requires a skilled workforce, including technicians, engineers, and assembly workers. By establishing manufacturing plants in various regions, these factories can create employment opportunities and stimulate economic growth. Furthermore, sourcing materials locally can reduce transportation costs and carbon emissions associated with long-distance supply chains.

The versatility of gabion wire mesh also extends to various uses beyond construction. In landscaping, gabions can be utilized for decorative walls, garden beds, and seating areas, offering an aesthetic appeal while maintaining functionality. They are also widely employed in environmental protection projects, such as stream bank stabilization and slope erosion control, making them an invaluable asset for engineers and environmentalists alike.

In conclusion, gabion wire mesh factories are indispensable in the modern construction landscape. They provide high-quality materials essential for building durable and sustainable structures while promoting eco-friendly practices. By fostering local economies and offering versatile solutions for various applications, these factories contribute significantly to the construction and landscaping industries. As the world continues to prioritize sustainability, the role of gabion wire mesh and its manufacturers will undoubtedly grow, paving the way for innovative solutions that balance development with environmental stewardship.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025