-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 30, 2024 02:26 Back to list

Galvanized Steel Grating Manufacturing Facility Overview and Insights

The Importance of Galvanized Steel Grating Factories

In the world of construction and industrial sectors, safety and reliability are paramount. One of the essential components ensuring both safety and efficiency is the use of grating, particularly galvanized steel grating. Galvanized steel grating has gained popularity due to its unique properties and manufacturing processes that cater to various industrial applications. This article explores the significance of galvanized steel grating factories, their production processes, and the benefits of using galvanized steel grating.

Understanding Galvanized Steel Grating

Galvanized steel grating is a type of flooring system made from steel that has undergone a galvanization process. This process involves dipping steel into molten zinc, creating a corrosion-resistant coating that extends the life of the material. Galvanized steel grating is known for its strength, durability, and resistance to rust, making it an ideal choice for environments exposed to harsh conditions, such as wastewater treatment plants, chemical processing facilities, and outdoor industrial areas.

The Role of Galvanized Steel Grating Factories

Galvanized steel grating factories play a crucial role in the supply chain for construction and manufacturing industries. These factories are responsible for producing high-quality grating products that meet various standards and specifications. The production process typically involves several key stages

1. Material Selection The process begins with the careful selection of high-grade steel, ensuring that the final product will possess the desired tensile strength and durability.

2. Fabrication The selected steel is then cut, welded, and assembled into desired grating patterns and sizes. Factories can customize designs based on client requirements, ensuring versatility in application.

3. Galvanization Once the grating is fabricated, it undergoes the galvanization process. This step is crucial as it provides the necessary protection against corrosion. The molten zinc coating bonds with the steel, creating a robust barrier that can withstand corrosive environments.

4. Quality Control Galvanized steel grating is subjected to rigorous quality control measures. This includes tests for strength, finish, and corrosion resistance to ensure that the products meet industry standards and customer specifications.

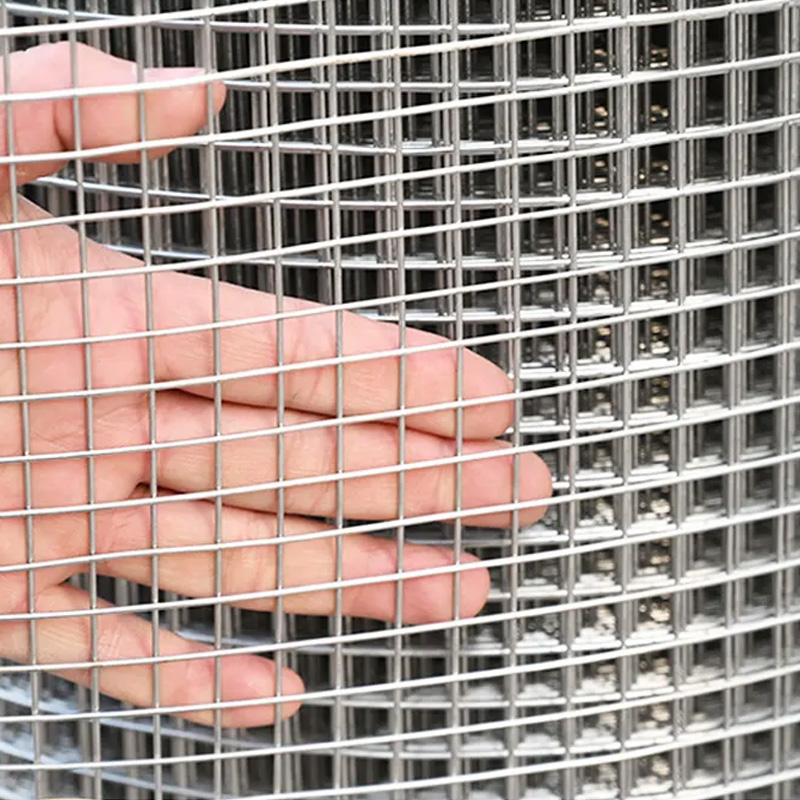

galvanized steel grating factory

5. Packaging and Distribution After passing quality checks, the grating is meticulously packaged to prevent damage during transit, ensuring that it arrives at its destination in perfect condition.

Benefits of Using Galvanized Steel Grating

The benefits of using galvanized steel grating are numerous, making it a preferred choice in various industries

- Corrosion Resistance The galvanization process provides an effective shield against rust and corrosion, significantly extending the life of the grating.

- Strength and Durability Galvanized steel grating is capable of bearing heavy loads while maintaining its structural integrity, making it suitable for high-traffic areas and industrial applications.

- Low Maintenance Due to its corrosion-resistant properties, galvanized steel grating requires minimal maintenance, leading to cost savings over time.

- Versatility Available in various sizes and styles, galvanized steel grating can be used in a wide range of settings—from walkways and platforms to stair treads and drainage covers.

- Safety The slip-resistant surfaces of galvanized steel grating help prevent accidents in both industrial and commercial environments, enhancing workplace safety.

Conclusion

In conclusion, galvanized steel grating factories are integral to supplying reliable and high-quality grating systems essential for numerous industrial applications. Their ability to produce durable, corrosion-resistant, and customizable grating solutions meets the demands of modern construction and manufacturing. As industries continue to emphasize safety, reliability, and efficiency, the role of galvanized steel grating and its dedicated factories will only grow in importance. Investing in galvanized steel grating not only ensures a robust solution for flooring and safety applications but also reflects a commitment to quality and long-term performance in industrial settings.

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025