-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Okt . 15, 2024 01:05 Back to list

2mm Galvanized Steel Wire Manufacturer for Durable Construction Applications

The Production Process of 2mm Galvanized Steel Wire A Comprehensive Overview

In today's industrial landscape, galvanized steel wire plays a crucial role in a variety of applications, ranging from construction to agriculture. One of the most commonly produced diameters is 2mm. This article explores the production process of 2mm galvanized steel wire, highlighting key aspects of its manufacturing, advantages, and applications.

Understanding Galvanization

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent corrosion. This is particularly important for materials used in outdoor environments or in situations where moisture is present. The process not only extends the lifespan of the steel wire but also ensures that it remains sturdy and reliable, making it ideal for demanding applications. The most common methods of galvanization include hot-dip galvanizing and electro-galvanizing.

Manufacturing Process

1. Raw Material Selection The journey of 2mm galvanized steel wire begins with selecting high-quality low-carbon steel wire rods. These rods provide the necessary strength and flexibility, enabling the final product to withstand various stresses.

2. Wire Drawing The steel rods are then processed through a series of wire drawing machines. This involves pulling the rods through die plates that gradually reduce their diameter to the desired 2mm size. The drawing process not only shapes the wire but also enhances its tensile strength.

3. Cleaning and Annealing Once the wire reaches 2mm, it undergoes a cleaning process to remove any impurities, rust, or oil. This is typically done using acidic solutions or mechanical methods. Following this, the wire is annealed—heated and then slowly cooled—to improve its ductility and ensure that it can be easily manipulated without breaking.

4. Galvanization After the wire is cleaned and conditioned, it enters the galvanization stage. In the hot-dip galvanization method, the wire is immersed in a bath of molten zinc at temperatures around 450°C. This allows the zinc to bond with the steel, forming a durable layer of protection. The thickness of the zinc coating can be controlled based on specifications, resulting in varying levels of corrosion resistance.

5. Cooling and Inspection Once galvanized, the wire is cooled, often using water jets. The wire is then inspected for quality assurance, ensuring that it meets industry standards. Testing may include checking the zinc coating thickness, tensile strength, and flexibility.

galvanized steel wire 2mm factory

6. Spooling and Packaging After passing the inspection, the 2mm galvanized steel wire is wound onto spools or coils for storage and transportation. Proper packaging is essential to prevent damage during transit and to make handling easier for customers.

Advantages of 2mm Galvanized Steel Wire

- Corrosion Resistance The zinc coating provides a robust barrier against rust and corrosion, making the wire suitable for outdoor applications and harsh environments.

- Durability This wire type is designed to withstand mechanical stress, ensuring longevity even when subjected to tension.

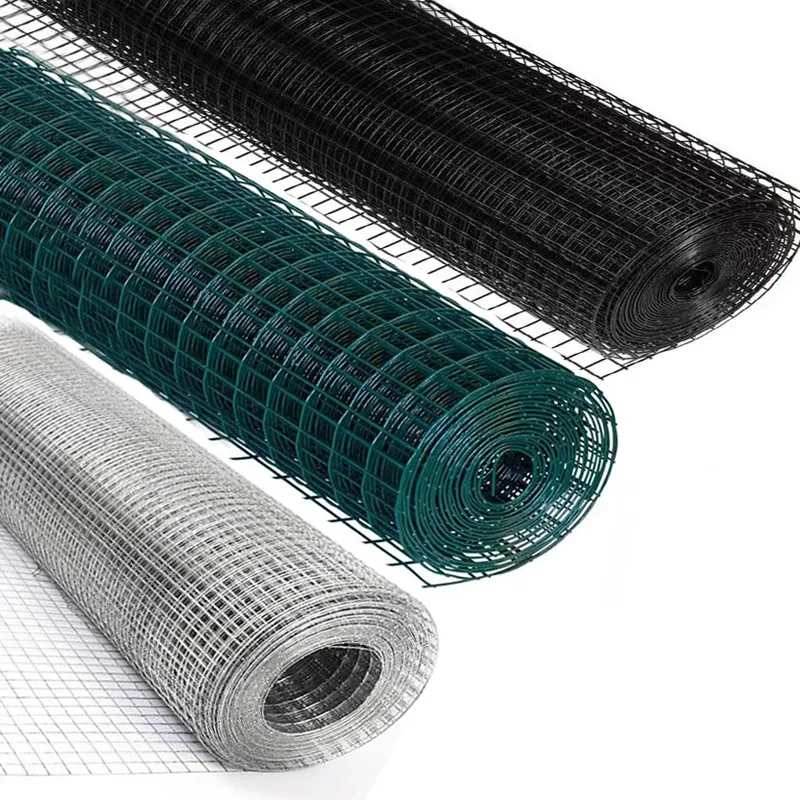

- Versatility 2mm galvanized steel wire can be used in a wide range of applications, including fencing, construction, baling, and even crafting projects.

- Cost-Effectiveness While the initial investment in galvanized steel wire may be higher than that of untreated wire, the reduced maintenance costs and longevity make it a cost-effective choice in the long run.

Applications of 2mm Galvanized Steel Wire

The applications of 2mm galvanized steel wire are extensive. In construction, it is often used for reinforcing concrete, securing structures, and creating mesh for support. In the agricultural sector, it is used in fencing, trellises, and as binding wire for crops. Moreover, artists and crafters utilize this wire for various projects due to its malleability and strength.

Conclusion

The production of 2mm galvanized steel wire is a refined process that involves careful selection of materials, precise manufacturing techniques, and stringent quality control measures. The resulting wire is not only strong and flexible but also resistant to corrosion, making it a preferred choice across multiple industries. As technology continues to advance, we can expect further improvements and innovations in the manufacturing processes, enhancing the performance and applications of galvanized steel wire even more.

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025