-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez. . 13, 2024 00:55 Back to list

Durable and Versatile Galvanized Steel Wire Mesh for Various Applications

The Versatility and Advantages of Galvanized Steel Wire Mesh

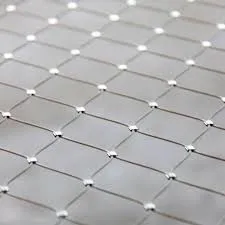

Galvanized steel wire mesh has emerged as a highly sought-after material in various industries due to its impressive strength, durability, and resistance to corrosion. Made from high-quality steel wire that has undergone a galvanization process—coating the steel with a protective layer of zinc—this type of wire mesh is designed to withstand harsh environmental conditions while maintaining its structural integrity. Below, we explore the key features, applications, and benefits of galvanized steel wire mesh.

Understanding the Galvanization Process

The galvanization process involves immersing steel wire in molten zinc or applying zinc through electroplating. This coating acts as a sacrificial barrier, preventing moisture from reaching the steel beneath and significantly prolonging its lifespan. The thickness of the zinc layer can vary, providing options suitable for different applications—from light-duty to heavy-duty use. The galvanization also enhances the aesthetic appeal of the mesh, giving it a shiny, metallic appearance that is often preferred in construction and design.

Key Features of Galvanized Steel Wire Mesh

1. Corrosion Resistance One of the most significant advantages of galvanized steel wire mesh is its resistance to rust and corrosion. The zinc coating protects the underlying steel, making it ideal for outdoor applications or in environments where exposure to moisture is unavoidable.

2. Strength and Durability Galvanized steel wire mesh is incredibly strong and can withstand substantial pressure and weight. Its high tensile strength makes it an excellent choice for structural applications, ensuring longevity and reliability.

3. Versatility Available in various sizes, wire gauges, and mesh patterns, galvanized wire mesh can be customized to suit a wide range of needs—from fencing and security applications to filtration and reinforcement.

4. Cost-Effectiveness Although the initial investment may be higher than some other materials, the long service life of galvanized steel wire mesh generally leads to cost savings over time. Reduced maintenance requirements and replacement frequencies contribute to its overall affordability.

Applications of Galvanized Steel Wire Mesh

galvanized steel wire mesh

The versatility of galvanized steel wire mesh allows it to be used in numerous applications across different industries

1. Construction It is commonly used in construction for concrete reinforcement, providing structural support and minimizing cracking during the curing process.

2. Fencing Galvanized wire mesh is often used for fencing solutions, whether for residential, commercial, or agricultural purposes. Its strength makes it an effective barrier against intruders or animals.

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, galvanized wire mesh is utilized in filters and ducts to prevent debris from entering sensitive equipment.

4. Industrial Uses Factories and manufacturing plants employ galvanized steel wire mesh in various forms, such as storage racks, shelves, and containers, to organize materials safely and efficiently.

5. Gardening and Landscaping Gardeners use galvanized wire mesh for creating trellises, plant supports, or protective barriers around plants to keep pests or animals at bay.

Conclusion

Galvanized steel wire mesh stands out as a robust, reliable, and versatile material suited for a multitude of applications. Its unique properties, including corrosion resistance, strength, and aesthetic appeal, make it the go-to choice for many construction, industrial, and agricultural needs. As businesses and individuals continue to seek durable solutions that promise longevity and cost-effectiveness, the demand for galvanized steel wire mesh will likely grow.

Whether you're looking to reinforce a structure, create fencing, or utilize it in filtration systems, investing in quality galvanized steel wire mesh is a decision that can yield substantial benefits in the long term. Its resilience coupled with adaptability ensures that it remains a pivotal material in both modern construction and various industrial applications, cementing its role in the future of material science and engineering.

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025