-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 10, 2025 12:22 Back to list

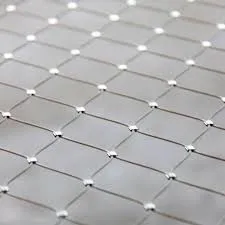

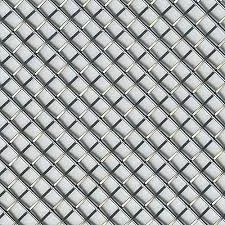

galvanized welded wire mesh

Concrete wire mesh, often overlooked yet undeniably crucial, stands at the forefront of construction innovations, revolutionizing both residential and commercial building landscapes. Drawing from years of hands-on experience and in-depth expertise, we delve into the intricacies of this unassuming material, providing insights that underscore its indispensability.

In terms of manufactural authoritativeness, leading industry standards govern the quality and durability of concrete wire mesh. The American Concrete Institute (ACI) and the American Society for Testing and Materials (ASTM) provide rigorous guidelines to ensure consistent quality control and performance assurance. This adherence to standardized practices fosters trust among construction professionals, allowing them to utilize wire mesh with confidence, knowing it meets or exceeds safety expectations. Concrete wire mesh's environmental and economic advantages also contribute to its sustainability credentials. The production process of wire mesh consumes less energy compared to traditional methods, resulting in a lower carbon footprint. Furthermore, its recyclability offers an added dimension of sustainability, making it a preferred choice among eco-conscious builders. When it comes to trustworthiness, customer reviews and industry feedback consistently echo the reliability of concrete wire mesh as a reinforcement solution. Builders report fewer post-construction issues such as cracking or settling, crediting the uniform stress distribution and enhanced structural integrity provided by the mesh. Product guarantees from reputable manufacturers further bolster consumer confidence, providing added peace of mind. In conclusion, concrete wire mesh transcends its role as a mere component of construction, embodying a fusion of innovation, practicality, and sustainability. Through enhanced load distribution, ease of handling, and adherence to stringent quality standards, it serves as a pivotal material in modern construction. Whether you're a contractor seeking efficiency or an architect aiming for durability, wire mesh offers a steadfast solution, backed by empirical evidence and authoritative guidelines. By employing concrete wire mesh, professionals build not only for the present but lay the groundwork for future architectural achievements.

In terms of manufactural authoritativeness, leading industry standards govern the quality and durability of concrete wire mesh. The American Concrete Institute (ACI) and the American Society for Testing and Materials (ASTM) provide rigorous guidelines to ensure consistent quality control and performance assurance. This adherence to standardized practices fosters trust among construction professionals, allowing them to utilize wire mesh with confidence, knowing it meets or exceeds safety expectations. Concrete wire mesh's environmental and economic advantages also contribute to its sustainability credentials. The production process of wire mesh consumes less energy compared to traditional methods, resulting in a lower carbon footprint. Furthermore, its recyclability offers an added dimension of sustainability, making it a preferred choice among eco-conscious builders. When it comes to trustworthiness, customer reviews and industry feedback consistently echo the reliability of concrete wire mesh as a reinforcement solution. Builders report fewer post-construction issues such as cracking or settling, crediting the uniform stress distribution and enhanced structural integrity provided by the mesh. Product guarantees from reputable manufacturers further bolster consumer confidence, providing added peace of mind. In conclusion, concrete wire mesh transcends its role as a mere component of construction, embodying a fusion of innovation, practicality, and sustainability. Through enhanced load distribution, ease of handling, and adherence to stringent quality standards, it serves as a pivotal material in modern construction. Whether you're a contractor seeking efficiency or an architect aiming for durability, wire mesh offers a steadfast solution, backed by empirical evidence and authoritative guidelines. By employing concrete wire mesh, professionals build not only for the present but lay the groundwork for future architectural achievements.

Latest news

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025