-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Mrz . 04, 2025 12:20 Back to list

Crimped Wire Mesh

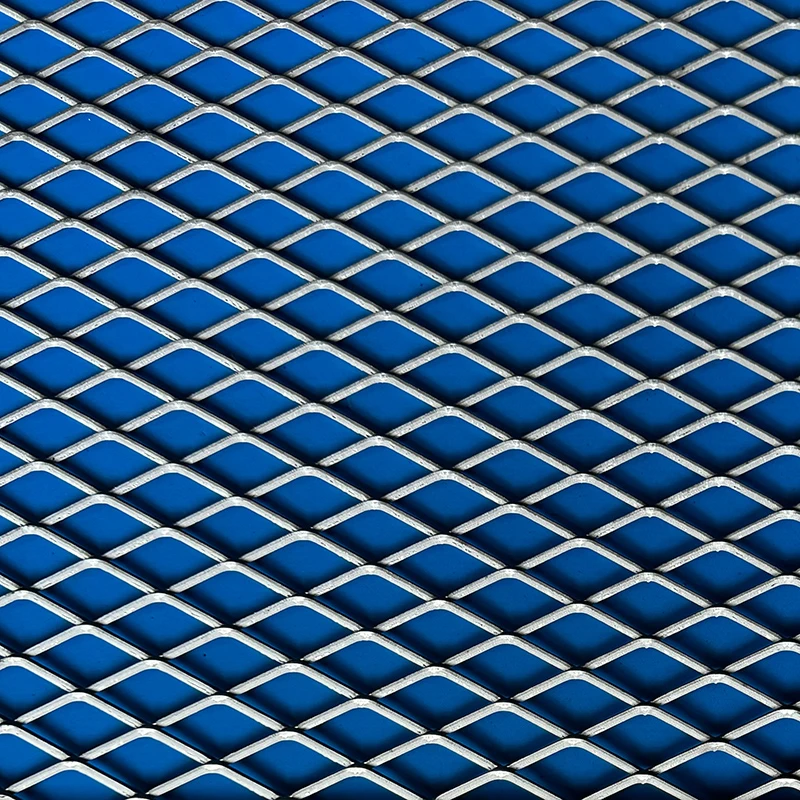

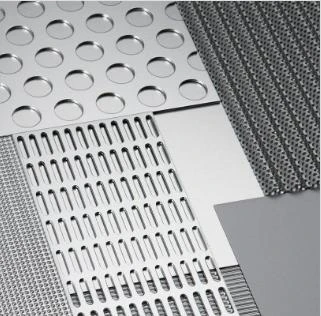

In a world where precision and reliability are more than just desirable traits, high-quality woven wire mesh stands as a cornerstone in a myriad of industrial and architectural applications. From its impeccable design to its significant role in various projects, woven wire mesh offers an unrivaled experience in blending functionality with aesthetic appeal.

Trustworthiness in high-quality woven wire mesh pivotally relies on compliance with these stringent standards, alongside transparent communication with customers. Manufacturers and suppliers are audited regularly to maintain certifications, an assurance of their commitment to delivering trusted products. Additionally, case studies and testimonials from various sectors provide concrete evidence of the mesh's reliability and long-term usability, forming the backbone of trust between supplier and consumer. The application spectrum for woven wire mesh is as wide as it is nuanced. In architectural designs, it is lauded for its aesthetic value, often used to create visually striking facades or intricate interior designs. Its transparency and sleek appearance complement modern architectural trends that prioritize open and light-filled spaces. In the industrial sector, its strength-to-weight ratio is unmatched, making it ideal for filtration, separation, and screening processes. These properties make woven wire mesh indispensable in industries such as oil and gas, mining, and agriculture, where efficient separation processes are critical. Real-world experience reinforces woven wire mesh's stature as a go-to solution in challenging applications. Consider its use in securing perimeters; security firms rely on the mesh's robustness to fortify barriers without compromising on visibility. Similarly, in filtration systems, engineers appreciate its precision in particle size control, affecting everything from water treatment facilities to food processing plants. Each application is a testament to the mesh's flexibility and its ability to conform to complex demands. In conclusion, high-quality woven wire mesh is more than just a product; it represents a fusion of traditional craftsmanship and modern technology, backed by years of expertise and industry validation. Its authority in the market is evidenced by widespread usage and compliance with rigorous standards. With trust as its cornerstone, suppliers continue to push the boundaries of what’s possible, working alongside industries worldwide to innovate and refine this essential material. As new challenges arise, woven wire mesh stands ready to meet them, a testament to its enduring relevance and unrivaled quality.

Trustworthiness in high-quality woven wire mesh pivotally relies on compliance with these stringent standards, alongside transparent communication with customers. Manufacturers and suppliers are audited regularly to maintain certifications, an assurance of their commitment to delivering trusted products. Additionally, case studies and testimonials from various sectors provide concrete evidence of the mesh's reliability and long-term usability, forming the backbone of trust between supplier and consumer. The application spectrum for woven wire mesh is as wide as it is nuanced. In architectural designs, it is lauded for its aesthetic value, often used to create visually striking facades or intricate interior designs. Its transparency and sleek appearance complement modern architectural trends that prioritize open and light-filled spaces. In the industrial sector, its strength-to-weight ratio is unmatched, making it ideal for filtration, separation, and screening processes. These properties make woven wire mesh indispensable in industries such as oil and gas, mining, and agriculture, where efficient separation processes are critical. Real-world experience reinforces woven wire mesh's stature as a go-to solution in challenging applications. Consider its use in securing perimeters; security firms rely on the mesh's robustness to fortify barriers without compromising on visibility. Similarly, in filtration systems, engineers appreciate its precision in particle size control, affecting everything from water treatment facilities to food processing plants. Each application is a testament to the mesh's flexibility and its ability to conform to complex demands. In conclusion, high-quality woven wire mesh is more than just a product; it represents a fusion of traditional craftsmanship and modern technology, backed by years of expertise and industry validation. Its authority in the market is evidenced by widespread usage and compliance with rigorous standards. With trust as its cornerstone, suppliers continue to push the boundaries of what’s possible, working alongside industries worldwide to innovate and refine this essential material. As new challenges arise, woven wire mesh stands ready to meet them, a testament to its enduring relevance and unrivaled quality.

Latest news

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025