-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 06, 2025 01:48 Back to list

Top-Quality Hot Dip Galvanized Wire Corrosion-Resistant & Durable

- Technical specifications and production methods distinguishing premium hot dip galvanized wire

- Current global market dynamics and regional production capacity statistics

- Comparative analysis of leading hot dip galvanized wire manufacturers and exporters

- Custom fabrication processes for specialized industrial requirements

- Performance metrics in critical infrastructure applications

- Innovations in galvanizing technology and corrosion resistance enhancement

- Selection criteria for quality-focused buyers of galvanized wire solutions

(hot dip galvanized wire)

Understanding Hot Dip Galvanized Wire Manufacturing Excellence

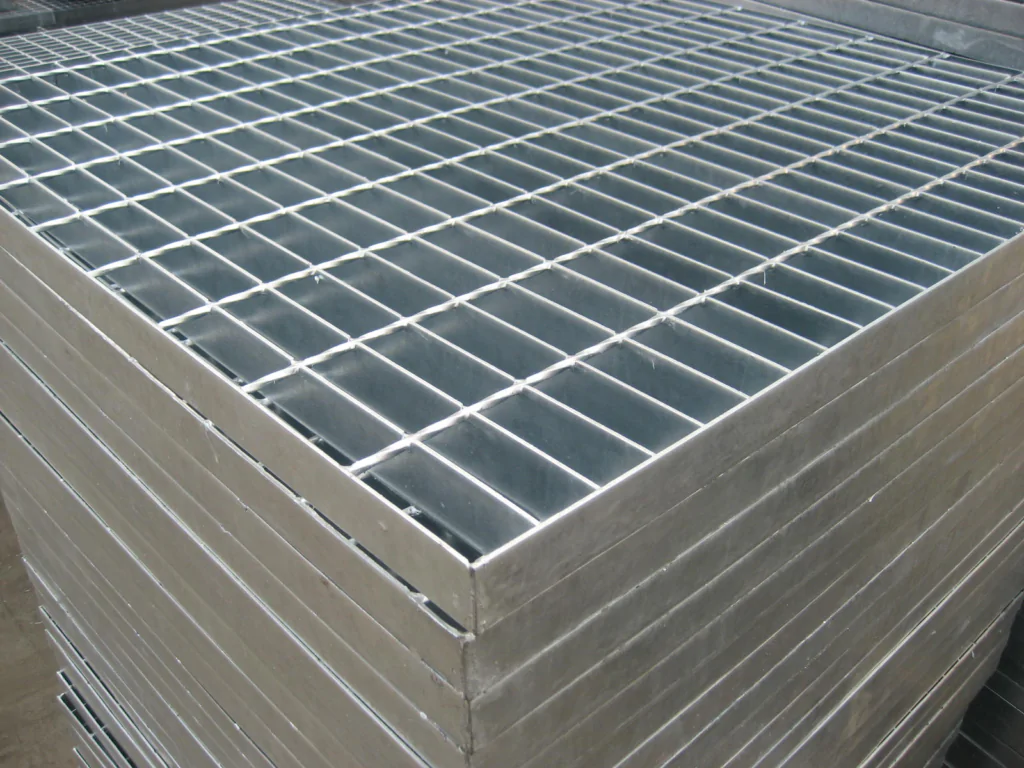

The production of premium hot dip galvanized wire involves precise metallurgical processes where steel wires undergo thorough cleaning before immersion in molten zinc baths maintained at 450°C. This creates a metallurgical bond forming zinc-iron alloy layers, providing corrosion protection exceeding standard electroplated coatings. Leading hot dip galvanized wire manufacturers utilize continuous galvanizing lines with automated viscosity control, achieving consistent coating weights of 250-300 g/m², significantly above the 120 g/m² minimum required by ISO 1461 standards. Post-galvanizing treatments include controlled air knife wiping to regulate coating thickness and specialized quenching processes that optimize ductility for downstream processing. Industry certifications like ISO 9001 and CQI-9 validate process control systems monitoring 15+ critical parameters including zinc bath composition, immersion duration, and cooling rates.

Global Market Dynamics and Production Capacities

Global production of hot dip galvanized wire exceeds 28 million metric tons annually, with China dominating 65% of output through integrated steel-wire manufacturing complexes. The European galvanized wire segment operates at 83% average capacity utilization, while Southeast Asian exporters have increased production by 18% year-over-year to meet infrastructure demands. Recent tariff adjustments have shifted trade patterns, with Indian exports to North America growing 27% after quality certification upgrades. Key industrial zones in Germany's Ruhr Valley and America's Rust Belt concentrate specialized hot dip galvanized wire mesh factories, leveraging proximity to automotive and construction sectors. Emerging environmental regulations now mandate wastewater zinc recovery systems, prompting 46% of European manufacturers to implement advanced filtration technologies within their galvanizing facilities.

Leading Hot Dip Galvanized Wire Manufacturers Comparison

| Manufacturer | Production Capacity (tons/month) | Zinc Coating Thickness (μm) | Diameter Range (mm) | Tensile Strength (MPa) | Export Destinations |

|---|---|---|---|---|---|

| Global Steel Wire Inc. | 22,000 | 50-85 | 0.15-6.00 | 350-1650 | 48 countries |

| EuroGalv Solutions | 15,500 | 55-90 | 0.20-5.50 | 400-1750 | EU, North America |

| AsiaGalv Technologies | 40,000 | 45-80 | 0.18-8.00 | 300-1550 | Global |

| American Wire Group | 18,000 | 60-95 | 0.30-4.50 | 375-1600 | Americas |

Custom Fabrication Capabilities

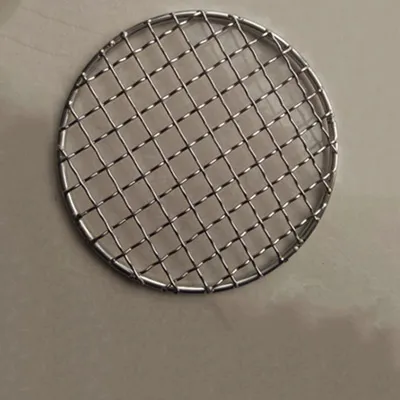

Specialized hot dip galvanized wire mesh factories offer engineering consultation for application-specific modifications. Through modified zinc bath chemistries containing 0.2% aluminium, manufacturers achieve tighter crystal structures enhancing salt spray resistance beyond 3,000 hours in marine environments. Diameter variations down to ±0.03mm precision are possible through tandem cold drawing lines with laser micrometers providing real-time calibration. Major agricultural fencing projects increasingly specify reverse-twist weaving patterns with 10% greater impact resistance, while architectural installations demand minimum-radius coiling capabilities down to 25cm diameter without coating compromise. Such tailored outputs now constitute 35% of premium manufacturers' order books, with design-to-production timelines compressed to 10 days through integrated CAD-CIM systems.

Documented Performance in Critical Applications

In Singapore's coastal metro barrier systems, triple-galvanized wire cables maintained 96.7% structural integrity after 15 years despite salt-laden atmospheric conditions. Highway guardrail manufacturers report zero corrosion failures after shifting from batch-galvanized to continuous-process wire meeting ASTM A641 Class 3 standards. Vineyard trellising applications demonstrate superior lifespan where 2.2mm hot dip wire outperformed polymer-coated alternatives by 18 years in Mediterranean climates. Recent advances include multi-pass galvanizing producing dual-layer zinc-iron alloy matrices with zinc carbonate patinas that actively regenerate surface protection. Rigorous field testing confirms these wires resist red rust formation for 26-34 years in temperate zones depending on environmental exposure classification.

Technological Advancements in Corrosion Protection

Innovative surface treatments now supplement traditional hot dip processes. Post-galvanizing chromate passivation creates self-healing yellow chromate layers that enhance salt spray resistance by 40% compared to conventional clear chromates. Nanocomposite sealing technologies penetrate microscopic zinc crystal boundaries, extending service life in acidic environments where standard galvanizing suffers premature deterioration. Leading German hot dip galvanized wire manufacturers employ inline eddy current sensors with 0.1μm precision to maintain coating uniformity on high-speed production lines exceeding 180 meters/minute. Environmental breakthroughs include zero-discharge galvanizing plants where zinc fumes undergo electrostatic precipitation and 97% of water inputs are recycled through three-stage treatment processes meeting EPA discharge requirements.

Selecting Quality-Driven Hot Dip Galvanized Wire Solutions

Industry-leading hot dip galvanized wire exporters prioritize metallurgical documentation including mill test reports confirming zinc adhesion exceeding 300g/m² and bending test certifications validating coating integrity after deformation. Purchasing specialists should verify dual ISO 1461 and ASTM A641 certifications while requiring factory audit reports documenting bath temperature controls and zinc purity exceeding 98.5%. Strategic buyers assess a manufacturer's in-house testing facilities, prioritizing those equipped with salt spray chambers performing 2000+ hour continuous exposure validations. Final selection criteria should include supply chain transparency – premium suppliers now provide batch-traceable production histories with digital access to specific galvanizing parameters applied to each coil. Reputable hot dip galvanized wire mesh factories typically maintain dedicated technical support teams performing comprehensive pre-delivery sample testing and application consultancy.

(hot dip galvanized wire)

FAQS on hot dip galvanized wire

Q: What are the key advantages of using hot dip galvanized wire?

A: Hot dip galvanized wire offers exceptional corrosion resistance due to its zinc coating. It provides longer lifespan in harsh environments compared to non-galvanized alternatives. This makes it ideal for outdoor applications like fencing and agriculture.

Q: How do I identify reliable hot dip galvanized wire manufacturers?

A: Look for manufacturers with ISO certifications and third-party quality test reports. Evaluate their production capacity, material sourcing transparency, and industry experience. Reputable manufacturers typically provide detailed product specifications and compliance documentation.

Q: What should I consider when selecting hot dip galvanized wire exporters?

A: Prioritize exporters with proven international shipping expertise and familiarity with destination-country standards. Verify their packaging methods for corrosion prevention during transit. Ensure they offer clear Incoterms agreements and reliable logistics partnerships.

Q: What product variations do hot dip galvanized wire mesh factories typically offer?

A: Factories commonly produce woven or welded meshes with different aperture sizes and wire gauges. Specialized offerings include PVC-coated galvanized mesh and custom-shaped panels. Mesh types range from poultry nets to heavy-duty gabion boxes.

Q: What industrial applications suit hot dip galvanized wire best?

A: It's widely used in construction reinforcement and animal containment fencing. Industrial applications include cable manufacturing, suspension systems, and marine infrastructure. The corrosion resistance also makes it perfect for highway barrier systems.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025