-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 17, 2024 11:20 Back to list

Iron Mesh Production Facility for High-Quality Industrial Applications and Custom Solutions

The Iron Mesh Factory Crafting Strength with Precision

In the fast-evolving world of construction and manufacturing, the iron mesh factory stands as a testament to engineering prowess and innovation

. These facilities are dedicated to producing high-quality iron mesh, which serves as a crucial component in various applications, ranging from construction reinforcement to filtration systems.Iron mesh, commonly known as welded wire mesh or rebar mesh, is utilized primarily for its strength and versatility. The production process begins with raw materials, typically high-quality steel wires. These wires are meticulously processed, cleaned, and prepared for welding. One of the key advantages of iron mesh is its ability to distribute loads evenly, providing structural integrity to buildings, bridges, and other infrastructures. This property is particularly vital in areas prone to seismic activities, where reinforcement can significantly enhance safety and durability.

In a typical iron mesh factory, automation plays a significant role in enhancing production efficiency. Advanced machinery is employed for the cutting, bending, and welding of the steel wires. Automated systems ensure precision, reducing wastage and improving the overall quality of the final product. Skilled workers oversee these processes, ensuring that everything runs smoothly and that the output meets rigorous industry standards. Such a systematic approach not only increases productivity but also minimizes operational risks.

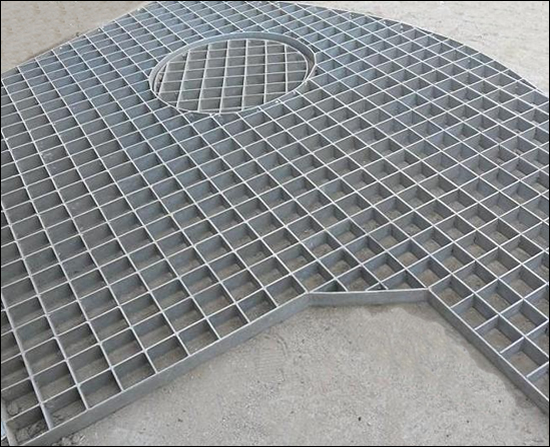

iron mesh factory

Moreover, sustainability is becoming a prominent focus within iron mesh factories. With the construction industry increasingly leaning towards eco-friendly practices, many manufacturers are exploring ways to reduce their carbon footprint. This includes using recycled steel and implementing eco-efficient technologies that minimize energy consumption during production. By prioritizing sustainability, iron mesh factories are not only contributing to modern architectural needs but also aligning with global efforts towards a greener planet.

The applications of iron mesh are vast and varied. In construction, it is primarily used for reinforcing concrete elements, such as slabs, walls, and pavements. The mesh improves tensile strength, preventing cracking and ensuring longevity. Beyond construction, iron mesh finds its way into industries such as agriculture, where it is used in fencing and animal enclosures, as well as in various filtration processes in chemical and food production sectors.

In conclusion, the iron mesh factory embodies innovation and quality in its production processes, catering to a wide range of industries. By leveraging technology and embracing sustainability, these factories ensure that their contribution to construction and manufacturing is both efficient and responsible. As urbanization continues to rise and the demand for robust infrastructure grows, the importance of iron mesh will undoubtedly increase, solidifying its role as a fundamental building block in modern society. The future of iron mesh production looks promising, with ongoing advancements poised to redefine the boundaries of engineering and construction practices.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025