-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 15, 2024 03:10 Back to list

Premium Electro Galvanized Wire with High Durability and Corrosion Resistance for Various Applications

The Importance of High-Quality Electro Galvanized Wire

In the world of manufacturing and construction, the choice of materials can significantly impact the overall performance and longevity of a project. One such material that stands out for its durability and reliability is high-quality electro galvanized wire. This article will explore the characteristics, manufacturing process, and applications of electro galvanized wire, emphasizing its importance in various industries.

Understanding Electro Galvanization

Electro galvanization is a process where a thin layer of zinc is electroplated onto steel wire. This method is distinct from hot-dip galvanization, where the wire is submerged in molten zinc. The electroplating process allows for more uniform coverage and a controlled thickness of the zinc layer, which can be essential for specific applications. The resulting wire exhibits enhanced corrosion resistance, which is crucial in environments where humidity, moisture, or other corrosive elements are present.

Advantages of High-Quality Electro Galvanized Wire

One of the key benefits of high-quality electro galvanized wire is its superior corrosion resistance. The zinc layer acts as a barrier, protecting the underlying steel from oxidation and rust, which can significantly extend the lifespan of the wire. In terms of mechanical properties, high-quality electro galvanized wire retains strength and flexibility, making it suitable for various applications, including fencing, wiring, and construction.

Another advantage is the improved aesthetic appeal of the wire. The electroplating process results in a smooth, shiny surface that can enhance the visual appeal of finished products. This quality is particularly important in applications where appearance matters, such as in decorative fencing or architectural elements.

Manufacturing Process

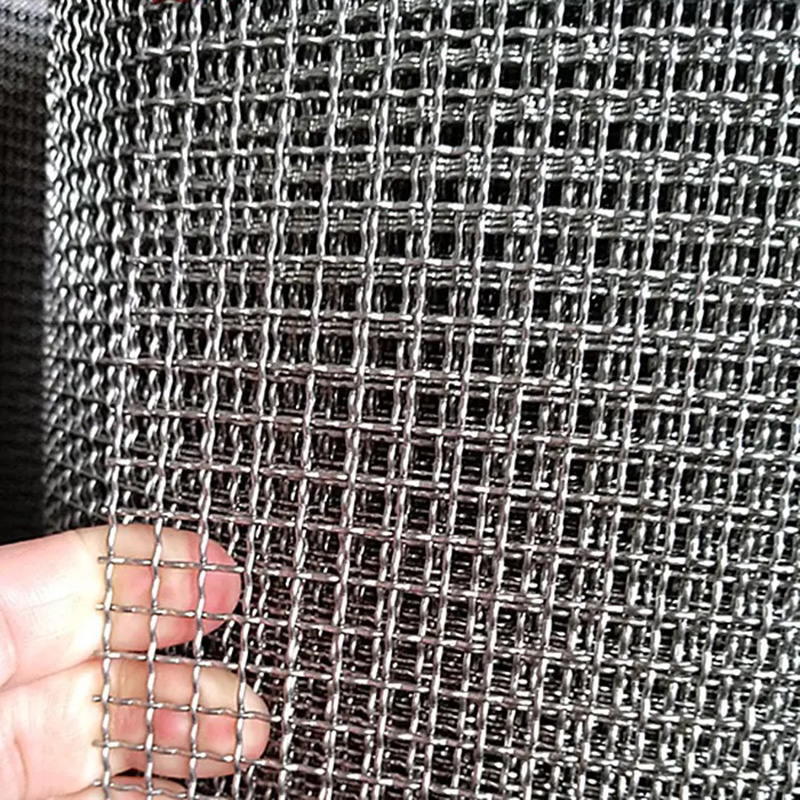

high quality electro galvanized wire

The production of high-quality electro galvanized wire involves several meticulous steps. First, high-grade steel wire is drawn to the desired diameter. Once the wire is prepared, it undergoes a cleaning process to remove any surface impurities, such as oils or dirt. This step is crucial, as any contaminants can affect the adhesion of the zinc layer.

After cleaning, the wire is submerged in an electrolyte solution, typically containing zinc salts. An electrical current is passed through the solution, causing zinc ions to deposit onto the wire's surface. The thickness of the zinc layer can be controlled by adjusting the duration of the electroplating process. Finally, the coated wire is dried and may undergo further treatments to enhance its properties, such as applying a protective polymer coating for additional corrosion resistance.

Applications of Electro Galvanized Wire

High-quality electro galvanized wire finds applications across a myriad of industries. In construction, it is often used for reinforcement in concrete, as well as for ties and anchors that require both strength and durability. The automotive industry utilizes electro galvanized wire for various components, benefiting from its resistance to corrosion caused by road salt and other environmental factors.

Moreover, in agricultural settings, it is commonly used for fencing to keep livestock in and pests out, ensuring durability in outdoor conditions. The wire's aesthetics also make it suitable for decorative purposes in landscaping and garden design.

Conclusion

In summary, high-quality electro galvanized wire is essential in numerous applications, thanks to its superior corrosion resistance, mechanical properties, and aesthetic appeal. Its manufacturing process highlights the importance of quality control in producing wire that meets industry standards. As industries continue to prioritize durability and performance, high-quality electro galvanized wire will undoubtedly play a critical role in the future of construction, manufacturing, and beyond.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025