-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 20, 2025 07:59 Back to list

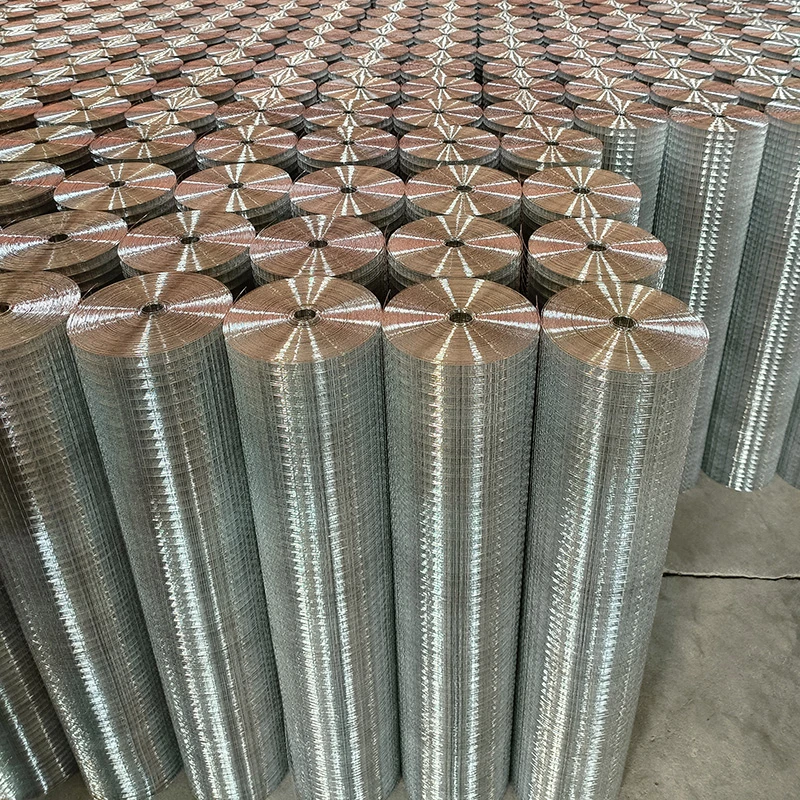

stainless steel crimped woven wire mesh

Stainless steel crimped woven wire mesh serves as an indispensable industrial and architectural resource known for its durability, functionality, and versatile applications. As a fundamental product in various industries, this mesh combines intricate weaving techniques with robust material properties, offering solutions that meet the high demands of today’s market.

For industrial use, the crimped woven wire mesh excels in filtering and screening applications. Industries such as mining, construction, and agriculture benefit significantly from its robust construction. The mesh efficiently separates materials of different sizes and provides optimal visibility for monitoring processes. Its resilience against mechanical stress and harsh chemicals extends its applicability to extreme industrial conditions, showcasing its versatility and reliability. Established manufacturers of stainless steel crimped woven wire mesh emphasize credibility and trustworthiness by adhering to international quality standards. Each batch undergoes rigorous testing for durability, tensile strength, and resistance to environmental factors, ensuring the end product meets the client’s specifications and industry requirements. By maintaining a transparent production process and customer-focused service, these manufacturers have built a reputation as authorities in the field, instilling confidence and loyalty among their clientele. Real-world experience with stainless steel crimped woven wire mesh underscores its performance across diverse settings. Many users attest to its cost-effectiveness, noting its long lifespan compared to alternative materials, which reduces the need for frequent replacements and repairs. Additionally, its adaptability allows for customization to fit unique project needs, providing solutions tailored to specific conditions. In summary, stainless steel crimped woven wire mesh stands out as a definitive leader in providing strength, reliability, and flexibility across numerous applications. Its expert manufacturing process, coupled with real-world performance, positions it as a credible and authoritative solution. Whether enhancing architectural aesthetics or meeting industrial demands, this mesh continues to uphold its standing as a trusted material in global markets.

For industrial use, the crimped woven wire mesh excels in filtering and screening applications. Industries such as mining, construction, and agriculture benefit significantly from its robust construction. The mesh efficiently separates materials of different sizes and provides optimal visibility for monitoring processes. Its resilience against mechanical stress and harsh chemicals extends its applicability to extreme industrial conditions, showcasing its versatility and reliability. Established manufacturers of stainless steel crimped woven wire mesh emphasize credibility and trustworthiness by adhering to international quality standards. Each batch undergoes rigorous testing for durability, tensile strength, and resistance to environmental factors, ensuring the end product meets the client’s specifications and industry requirements. By maintaining a transparent production process and customer-focused service, these manufacturers have built a reputation as authorities in the field, instilling confidence and loyalty among their clientele. Real-world experience with stainless steel crimped woven wire mesh underscores its performance across diverse settings. Many users attest to its cost-effectiveness, noting its long lifespan compared to alternative materials, which reduces the need for frequent replacements and repairs. Additionally, its adaptability allows for customization to fit unique project needs, providing solutions tailored to specific conditions. In summary, stainless steel crimped woven wire mesh stands out as a definitive leader in providing strength, reliability, and flexibility across numerous applications. Its expert manufacturing process, coupled with real-world performance, positions it as a credible and authoritative solution. Whether enhancing architectural aesthetics or meeting industrial demands, this mesh continues to uphold its standing as a trusted material in global markets.

Next:

Latest news

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025