-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Okt . 05, 2024 11:39 Back to list

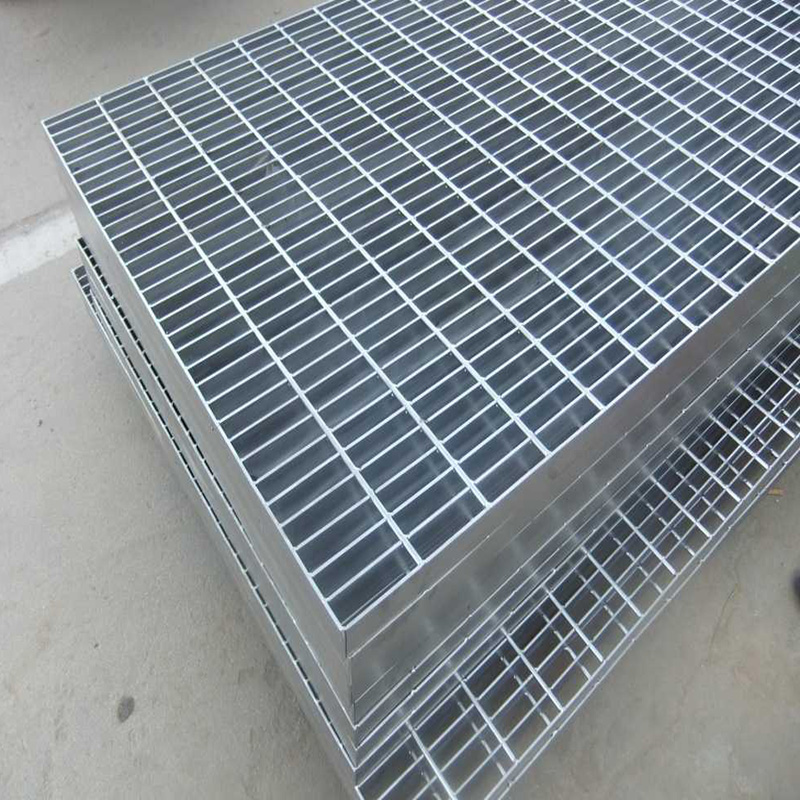

steel bridge grating factories

The Evolution and Impact of Steel Bridge Grating Factories

In the realm of civil engineering and infrastructure development, the significance of steel bridge grating cannot be overstated. Steel bridge gratings are utilized in various applications, providing essential safety and functionality in bridge construction. These gratings serve as load-bearing surfaces that enhance vehicular and pedestrian passage while also offering necessary drainage capabilities. The factories that produce these vital components have evolved considerably over the decades, reflecting advancements in technology, sustainability, and the increasing demands of modern infrastructure.

Historical Context

Steel grating has been a fundamental material in the construction industry since the mid-20th century when industrialization began to reshape the landscape of urban architecture. Early manufacturing processes were rudimentary, focusing primarily on the basic design and functionality of the gratings. As cities expanded and transportation networks grew more complex, the need for durable and efficient steel gratings became paramount. The introduction of more advanced metallurgical techniques revolutionized the production capabilities, allowing for greater customization and improved performance characteristics.

Technological Innovations

Steel bridge grating factories have embraced cutting-edge technologies to enhance their manufacturing processes. Automation and robotics have become integral in production lines, allowing for precise cutting, welding, and assembly of grating components. Computer Numerical Control (CNC) machines are now standard, enabling factories to produce intricate designs with minimal human intervention. This not only boosts productivity but also ensures quality consistency across batches.

Additionally, the integration of advanced materials science has contributed to the development of high-performance steel grades that resist corrosion, fatigue, and wear. This is particularly relevant in environments susceptible to harsh weather conditions or chemical exposure. Factories now employ sophisticated testing methods to ensure that the gratings meet or exceed relevant safety standards and performance specifications.

Sustainability and Eco-Friendly Practices

steel bridge grating factories

In recent years, there has been a growing emphasis on sustainability within the manufacturing sector, and steel bridge grating factories are no exception. The steel industry has made significant strides in reducing its environmental impact by adopting more sustainable practices. This includes using recycled steel in production, which not only conserves raw materials but also reduces energy consumption associated with steel manufacturing.

Factories are also investing in energy-efficient machinery and processes. Techniques such as lean manufacturing minimize waste and optimize resource use. Furthermore, many grating manufacturers are exploring innovative ways to design their products for disassembly, promoting recyclability at the end of a grating’s life cycle. This shift toward circular economy principles illustrates a broader commitment to environmental stewardship within the industry.

Market Trends and Future Outlook

The market for steel bridge gratings is experiencing growth driven by increased infrastructure spending globally. Governments are prioritizing the repair and maintenance of existing bridges while also investing in the construction of new projects to support urbanization and economic development. The demand for high-quality, durable steel gratings is set to rise, with factories positioned at the forefront of this industry shift.

Moreover, the ongoing development of smart cities will likely influence the evolution of steel grating design and fabrication. The incorporation of smart technologies such as sensors and monitoring systems into bridge gratings holds promise for enhanced safety and maintenance. These innovations enable real-time data collection about load conditions, wear and tear, and environmental factors, allowing for predictive maintenance and improved longevity of bridging systems.

Conclusion

Steel bridge grating factories play a crucial role in the construction and maintenance of infrastructure that supports our daily lives. As these factories continue to innovate through technology, sustainability practices, and responsiveness to market needs, they not only meet contemporary demands but also pave the way for future advancements. The evolution of steel bridge grating production encapsulates the dynamic interplay between engineering, environmental responsibility, and societal progress, ensuring that our infrastructures remain safe, efficient, and reliable for generations to come.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025