-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 10:45 Back to list

Welded Wire Mesh

In the realm of construction and industrial applications, welded wire mesh stands as an indispensable material renowned for its strength, durability, and versatility. Over the years, its usage has transformed from basic reinforcement to more complex architectural and infrastructural projects. This evolution underscores the expertise required to manufacture, implement, and innovate with this essential product.

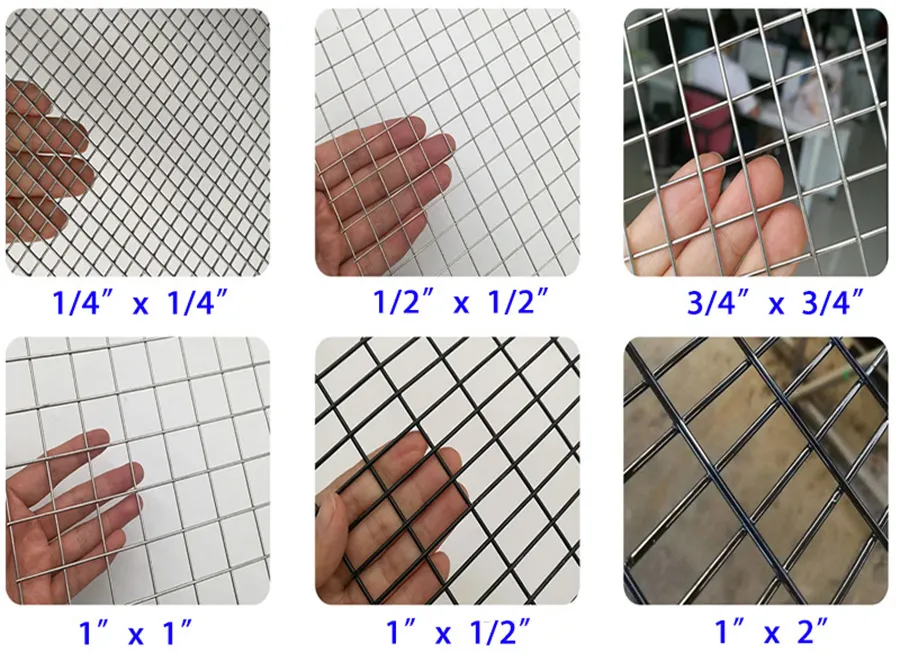

Trustworthiness in choosing a welded wire mesh supplier cannot be understated. Clients and contractors seek providers with a proven track record of consistent quality and adherence to international standards. Certifications, like ISO and ASTM, often serve as benchmarks of reputable manufacturers. Trust is further built through transparent supply chains and dedicated customer service, ensuring that stakeholders receive accurate information and support throughout their projects. For those involved in agricultural and livestock industries, welded wire mesh offers solutions for fencing and enclosures. Its sturdy nature makes it ideal for containing animals and protecting crops from wildlife. In such contexts, understanding the environmental impact and longevity of the mesh becomes crucial. Properly galvanized or coated meshes can extend service life, reducing maintenance costs and promoting sustainable practices in farm management. Moreover, the customization potential of welded wire mesh broadens its application scope. Tailored solutions can be engineered to meet specific design requirements, whether that means altering the mesh opening size, wire diameter, or overall dimensions. Such flexibility ensures that diverse industries can benefit from bespoke wire mesh solutions, whether used for security purposes, filtration processes, or artistic installations. In conclusion, welded wire mesh is a product that exemplifies excellence in materials engineering and design. Its various applications underscore the need for expertise and authority in its production and use. Choosing a reliable supplier ensures the mesh's integrity and performance, fostering trust and reliability across projects. As construction and industrial needs evolve, welded wire mesh remains at the forefront of providing innovative and practical solutions. This indispensable material continues to advance, driven by a commitment to quality, innovation, and meeting the complex demands of contemporary infrastructure development.

Trustworthiness in choosing a welded wire mesh supplier cannot be understated. Clients and contractors seek providers with a proven track record of consistent quality and adherence to international standards. Certifications, like ISO and ASTM, often serve as benchmarks of reputable manufacturers. Trust is further built through transparent supply chains and dedicated customer service, ensuring that stakeholders receive accurate information and support throughout their projects. For those involved in agricultural and livestock industries, welded wire mesh offers solutions for fencing and enclosures. Its sturdy nature makes it ideal for containing animals and protecting crops from wildlife. In such contexts, understanding the environmental impact and longevity of the mesh becomes crucial. Properly galvanized or coated meshes can extend service life, reducing maintenance costs and promoting sustainable practices in farm management. Moreover, the customization potential of welded wire mesh broadens its application scope. Tailored solutions can be engineered to meet specific design requirements, whether that means altering the mesh opening size, wire diameter, or overall dimensions. Such flexibility ensures that diverse industries can benefit from bespoke wire mesh solutions, whether used for security purposes, filtration processes, or artistic installations. In conclusion, welded wire mesh is a product that exemplifies excellence in materials engineering and design. Its various applications underscore the need for expertise and authority in its production and use. Choosing a reliable supplier ensures the mesh's integrity and performance, fostering trust and reliability across projects. As construction and industrial needs evolve, welded wire mesh remains at the forefront of providing innovative and practical solutions. This indispensable material continues to advance, driven by a commitment to quality, innovation, and meeting the complex demands of contemporary infrastructure development.

Latest news

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025