-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 11:20 Back to list

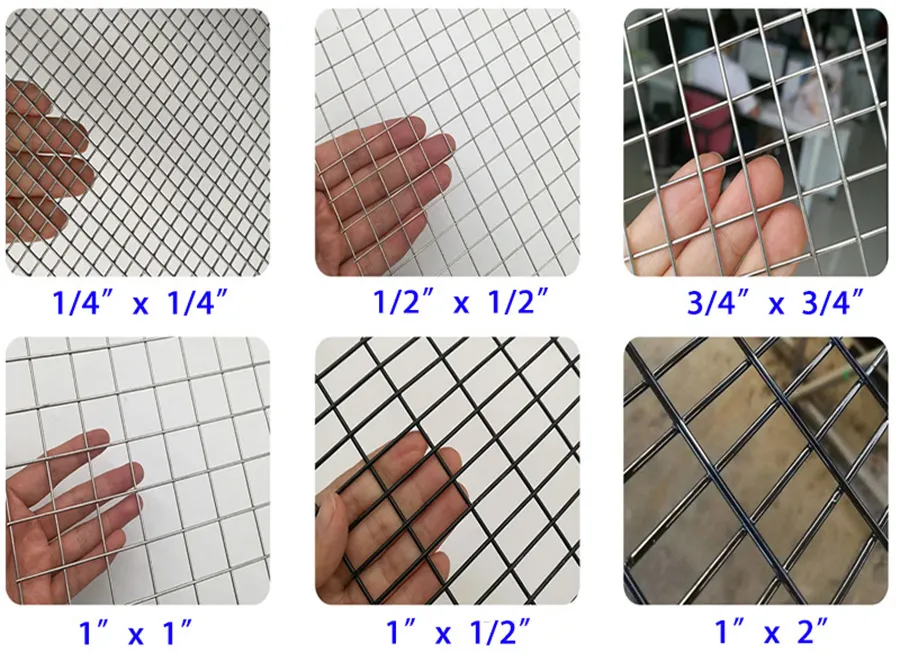

Welded Wire Mesh Supplier

Welded wire mesh is an integral component in various industries, celebrated for its versatility, strength, and reliability. Drawing from extensive expertise and authoritative insights, this article delves into the profound impact of welded wire mesh in contemporary construction, agriculture, and beyond, underscoring its unmatched value and trustworthiness.

Security is another domain where the welded wire mesh shines. From high-security prisons to urban infrastructure, its robust construct offers a formidable barrier against intrusion. Security professionals emphasize its non-scaling nature and the difficulty it poses for potential breaches. The mesh can be further reinforced or coated with anti-cut properties, elevating its status as a trusted security measure. This authoritative application in security solutions reinforces the trust placed in welded wire mesh by institutions worldwide. From an environmental standpoint, welded wire mesh aligns with sustainable practices, appealing to eco-conscious developers. Its production requires fewer raw materials compared to other reinforcement alternatives, and it boasts a long lifespan, reducing the need for frequent replacements. This aspect not only minimizes environmental impact but also provides a cost-effective solution for projects mindful of their carbon footprint. Trust in welded wire mesh is thus reinforced by its contribution to sustainability goals. The credibility of welded wire mesh is showcased through numerous case studies and real-world applications. It has played a pivotal role in landmark projects, where its reliability was rigorously tested against stringent standards. Expert testimonials often highlight its role in reducing construction timelines and enhancing the structural integrity of ambitious builds. In summary, welded wire mesh embodies a synthesis of experience, expertise, authoritativeness, and trustworthiness. As we continue to push the boundaries of architectural design and agricultural efficiency, the role of welded wire mesh becomes increasingly critical. Its presence is a vivid reminder of how advanced material engineering can elevate industry standards, providing solutions that are both innovative and dependable. Embracing welded wire mesh means investing in a legacy of quality and reliability, a commitment echoing through every project it reinforces.

Security is another domain where the welded wire mesh shines. From high-security prisons to urban infrastructure, its robust construct offers a formidable barrier against intrusion. Security professionals emphasize its non-scaling nature and the difficulty it poses for potential breaches. The mesh can be further reinforced or coated with anti-cut properties, elevating its status as a trusted security measure. This authoritative application in security solutions reinforces the trust placed in welded wire mesh by institutions worldwide. From an environmental standpoint, welded wire mesh aligns with sustainable practices, appealing to eco-conscious developers. Its production requires fewer raw materials compared to other reinforcement alternatives, and it boasts a long lifespan, reducing the need for frequent replacements. This aspect not only minimizes environmental impact but also provides a cost-effective solution for projects mindful of their carbon footprint. Trust in welded wire mesh is thus reinforced by its contribution to sustainability goals. The credibility of welded wire mesh is showcased through numerous case studies and real-world applications. It has played a pivotal role in landmark projects, where its reliability was rigorously tested against stringent standards. Expert testimonials often highlight its role in reducing construction timelines and enhancing the structural integrity of ambitious builds. In summary, welded wire mesh embodies a synthesis of experience, expertise, authoritativeness, and trustworthiness. As we continue to push the boundaries of architectural design and agricultural efficiency, the role of welded wire mesh becomes increasingly critical. Its presence is a vivid reminder of how advanced material engineering can elevate industry standards, providing solutions that are both innovative and dependable. Embracing welded wire mesh means investing in a legacy of quality and reliability, a commitment echoing through every project it reinforces.

Next:

Latest news

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025