-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dez . 15, 2024 15:00 Back to list

welded wire mesh factories

The Significance and Versatility of Welded Wire Mesh Factories

Welded wire mesh is a versatile construction material that finds its applications across various industries. As the demand for such products continues to grow, welded wire mesh factories play a pivotal role in meeting these needs with efficiency and precision.

Understanding Welded Wire Mesh

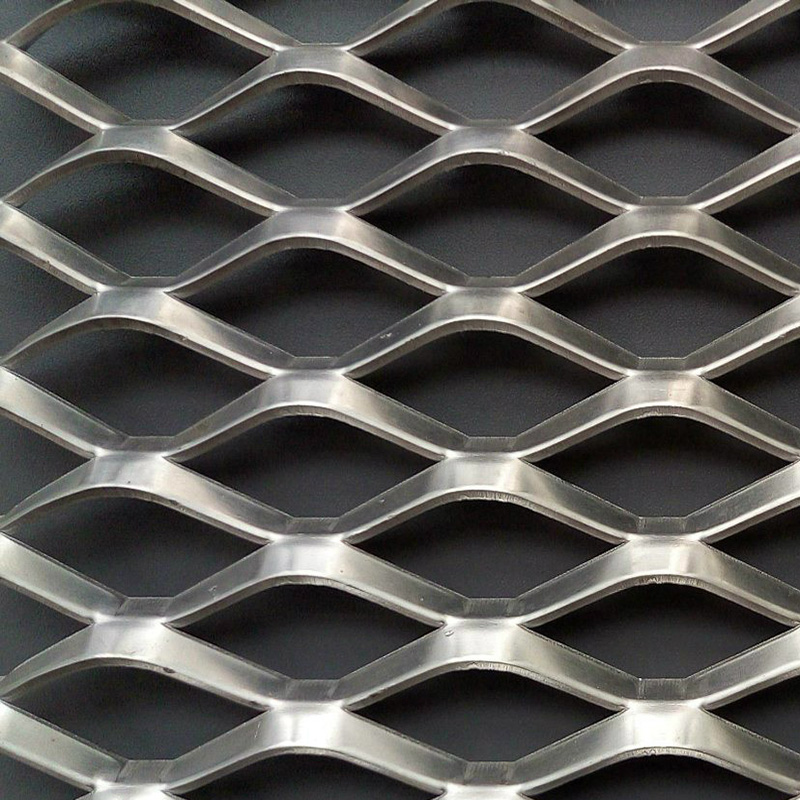

Welded wire mesh is created by welding together strands of wire to form a grid-like structure. Typically made from steel or stainless steel, the wires are arranged in a series of rows and columns. The welding process ensures that the joints are strong and durable, making this material ideal for a variety of applications. Welded wire mesh is commonly used in construction, agriculture, mining, and animal husbandry due to its strength, durability, and ability to be customized.

The Manufacturing Process

The manufacturing process of welded wire mesh involves several steps. It begins with the selection of raw materials, where factories often opt for high-quality steel wire. The wire is then drawn to the desired diameter and cut to length before being arranged into a grid pattern. Next comes the welding phase, where the wires are electrically fused at their intersections to create a robust mesh. After welding, the product undergoes inspection for quality assurance and may be subjected to surface treatments such as galvanization to enhance corrosion resistance. Finally, the welded wire mesh is packaged and prepared for distribution.

Application Across Industries

One of the key advantages of welded wire mesh is its adaptability. In construction, it is often used for reinforcement in concrete and foundations, providing the necessary tensile strength. Furthermore, welded wire mesh is frequently utilized for fencing in agricultural settings, ensuring the protection of crops and livestock. The mining industry employs welded wire mesh for ground support and safety, preventing collapse in tunnels and pits.

welded wire mesh factories

In addition to these applications, welded wire mesh is also used in manufacturing processes for creating partitions, storage racks, and cages. Its versatility extends to home improvement projects, where it can be used in landscaping, as garden fences, or even as decorative elements in modern architecture.

Advantages of Using Welded Wire Mesh

The popularity of welded wire mesh can be attributed to several factors. Firstly, the strength-to-weight ratio of welded wire mesh makes it a cost-effective solution, allowing for reduced material usage without compromising on strength. Secondly, the uniformity of its construction provides excellent load distribution and minimizes the risk of structural failure. Additionally, the ease of installation and flexibility in design offers contractors and builders the opportunity to tailor solutions to specific project requirements.

Furthermore, welded wire mesh can be produced in various sizes, shapes, and mesh openings, catering to a wide range of applications. This flexibility allows manufacturers to meet the unique demands of their clients efficiently.

Sustainability and Innovation

As the world evolves, so too do welded wire mesh factories. Many are adopting sustainable practices by sourcing recyclable materials and implementing energy-efficient manufacturing processes. Innovations in technology, such as automated welding machines and advanced quality control systems, are improving production efficiency and product quality.

Conclusion

Welded wire mesh factories are integral to numerous industries, providing a vital resource that enhances safety and efficiency across various applications. With ongoing advancements and a focus on sustainability, the future of welded wire mesh looks promising. As construction practices evolve and the demand for innovative materials increases, welded wire mesh will undoubtedly continue to play a significant role in shaping more resilient infrastructures and sustainable practices across the globe.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025