-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 16, 2024 19:41 Back to list

Durable Custom Heavy-Duty Wire Mesh for Various Applications and Industrial Needs

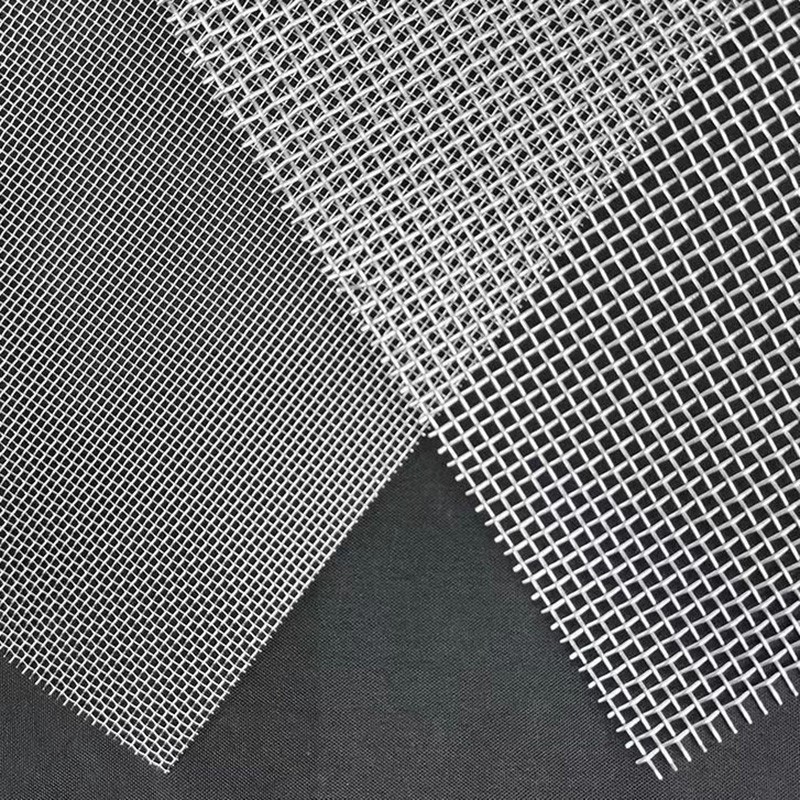

Custom Heavy Duty Wire Mesh The Versatile Solution for Various Applications

In today's industrial landscape, the need for durable and reliable materials is paramount. Among the plethora of options available, custom heavy duty wire mesh stands out as a versatile and robust solution. This article will delve into the features, benefits, and applications of custom heavy duty wire mesh, illustrating why it has become a favored choice across numerous industries.

Understanding Heavy Duty Wire Mesh

Heavy duty wire mesh is engineered from high-strength metals, designed to withstand significant stress and heavy loads. It is typically constructed using thicker wires, providing enhanced durability compared to standard wire mesh. The integration of custom design options allows businesses to tailor the mesh's specifications to meet their precise needs, whether they require specific dimensions, coatings, or wire gauge.

Key Features

One of the standout features of custom heavy duty wire mesh is its adaptability. It can be manufactured in various sizes and shapes, accommodating projects ranging from industrial machinery to architectural applications. The mesh is available in different materials, including stainless steel, galvanized steel, and aluminum, each offering unique advantages in terms of corrosion resistance, strength, and weight.

Another significant attribute is its strength-to-weight ratio. Despite its robust nature, heavy duty wire mesh can remain lightweight, making it easier to handle and install. Customization enables end-users to choose the mesh pattern, with options such as square, rectangular, or diamond shapes, providing aesthetic flexibility alongside functional excellence.

Benefits of Customization

custom heavy duty wire mesh

The ability to customize heavy duty wire mesh brings several advantages. Firstly, tailored solutions ensure that the specific requirements of a project are met with precision. For instance, a construction project may necessitate mesh with specific load-bearing capabilities, while an agricultural application might prioritize corrosion resistance. Customization eliminates the guesswork and ensures optimal performance.

Moreover, custom heavy duty wire mesh can significantly enhance safety. In applications such as security fencing or barriers, the mesh can be designed to resist forced entry or withstand extreme weather conditions. This level of customization leads to increased peace of mind for businesses and individuals alike.

Applications Across Industries

The applications for custom heavy duty wire mesh are extensive and span numerous sectors. In construction, it is frequently used as reinforcement for concrete and as formwork for walls and floors. In the agricultural industry, it provides a robust barrier against pests and protects crops, while also serving as enclosures for livestock.

The manufacturing sector utilizes heavy duty wire mesh in filtration systems and conveyor belts, benefiting from its durability and the ability to be designed for specific filtration needs. Additionally, in the automotive industry, it is employed in the production of parts requiring high strength and stability.

Conclusion

In conclusion, custom heavy duty wire mesh represents an essential material in various industries, thanks to its strength, versatility, and customization options. Whether you are looking for solutions in construction, agriculture, or manufacturing, this type of wire mesh can be tailored to meet your distinct requirements, ensuring peak performance and safety. As industries continue to evolve, the demand for reliable materials like custom heavy duty wire mesh is expected to grow, reinforcing its critical role in shaping the future of construction and manufacturing. Embracing this robust solution not only enhances operational efficiency but also contributes to the sustainability of projects across various domains.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025