-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 12, 2024 16:02 Back to list

galvanised wire mesh factories

Galvanised Wire Mesh Factories An Overview

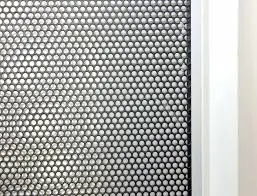

Galvanised wire mesh is an essential component in various industries, providing durability, strength, and resistance to corrosion. The manufacturing of galvanised wire mesh involves a meticulous process that ensures high-quality products suitable for a wide range of applications, including construction, agriculture, and fencing. This article delves into the structure and significance of galvanised wire mesh factories, highlighting their role in producing reliable materials for both industrial and domestic needs.

At the heart of a galvanised wire mesh factory is the production line, where raw materials are transformed into finished products. The process begins with the selection of high-quality steel wire, which is drawn to the desired diameter. The wire is then fed through a galvanising process, typically involving either hot-dip galvanising or electro-galvanising. Hot-dip galvanising is the most common process, where the wire is submerged in molten zinc, resulting in a thick layer of zinc coating that provides excellent corrosion resistance. This method is preferred for applications exposed to harsh environmental conditions, ensuring a longer lifespan for the wire mesh.

Once the galvanisation process is complete, the wire is woven into different mesh patterns and sizes according to customer specifications. Factories utilize advanced machinery that can produce various mesh configurations, including square, rectangular, and hexagonal patterns. This versatility allows galvanised wire mesh to cater to diverse applications, from reinforcing concrete structures to providing security in residential settings.

galvanised wire mesh factories

Quality control is paramount in galvanised wire mesh production. Factories implement strict testing protocols to ensure that each batch meets industry standards. This includes checks for dimensional accuracy, tensile strength, and corrosion resistance. By adhering to these quality assurance measures, factories maintain a reputation for delivering reliable and durable products.

The demand for galvanised wire mesh has grown significantly across sectors. In construction, it is used for concrete reinforcement, scaffolding, and as a barrier for heavy-duty applications. Meanwhile, in agriculture, galvanised wire mesh serves as fencing for livestock and crop protection. Its ability to withstand harsh weather conditions makes it a preferred choice for outdoor applications.

Sustainability is increasingly becoming a focus for galvanised wire mesh factories. Many manufacturers are adopting eco-friendly practices, such as recycling zinc and steel materials, minimizing waste, and using energy-efficient production methods. This shift not only benefits the environment but also appeals to consumers who prioritize sustainability in their purchasing decisions.

In conclusion, galvanised wire mesh factories play a crucial role in meeting the ever-growing demands of various industries. Through advanced manufacturing processes, stringent quality control, and a focus on sustainability, these factories ensure that they produce high-quality products that contribute to the safety and efficiency of numerous applications worldwide. As industries continue to evolve, the importance of reliable galvanised wire mesh will undoubtedly persist, further emphasizing the significance of these manufacturing plants.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025