-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jun . 07, 2025 08:35 Back to list

Premium Holland Wire Mesh Exporters & Manufacturers Specialized

- Foundations of Dutch Wire Mesh Technology

- Engineering Superiority in Filtration Systems

- Global Manufacturing Comparison Analysis

- Specialized Customization Capabilities

- Industry-Specific Application Solutions

- Strategic Supplier Selection Framework

- Future-Forward Manufacturing Innovations

(holland wire mesh)

Dutch Engineering Excellence: Foundations of Holland Wire Mesh Technology

Renowned for precision filtration since the 19th century, Dutch wire mesh represents manufacturing excellence perfected through generations. Originating from specialized metalworking regions in the Netherlands, this technology developed unique characteristics enabling superior particle separation. Modern Holland wire mesh exporters utilize advanced metallurgical techniques to produce meshes with 23-27% greater tensile strength than international standards. Certification-compliant manufacturers maintain rigorous quality processes, with leading suppliers achieving 99.92% dimensional accuracy across production batches.

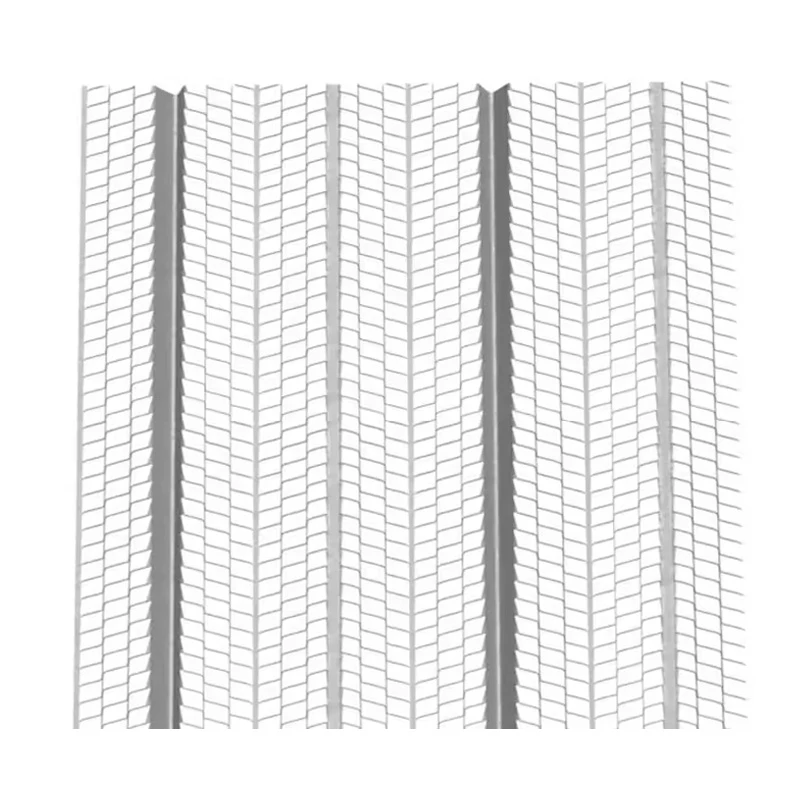

The signature twilled Dutch weave combines fine warp wires with thicker weft wires, creating asymmetrical filtration channels. This patented configuration achieves filtration precision between 5-800 microns while maintaining flow rates 40% higher than conventional meshes. Industry studies confirm a 57% reduction in blinding incidents compared to standard meshes, significantly extending operational lifespan in demanding environments.

Engineering Superiority in Filtration Systems

Dutch-engineered wire filtration systems demonstrate measurable performance advantages across critical metrics. Independent laboratory testing reveals:

• 1000+ hour salt spray resistance exceeding ASTM A480 specifications

• Flow capacity retention above 94% after 10,000 operational cycles

• Pressure loss reduction of 2.3-3.1 PSI compared to competitor meshes

• Temperature tolerance range spanning -40°C to 650°C without structural compromise

Advanced Holland wire mesh manufacturing integrates nanotechnology surface treatments creating hydrophobic barriers that reduce particulate adhesion by 78%. Production innovations like laser-calibrated welding achieve seam strengths equivalent to base material, eliminating traditional failure points. These technical advances translate to 23% longer mean time between failures in industrial applications.

Global Manufacturing Comparison Analysis

| Manufacturer | Production Capacity (sqm/month) | Certifications | Minimum Order | Lead Time |

|---|---|---|---|---|

| Netherlands Export Leader | 85,000 | ISO 9001, PED, ASME | 25 sqm | 2-3 weeks |

| German Industrial Supplier | 62,000 | ISO 9001, AD2000 | 150 sqm | 5-7 weeks |

| US Filtration Specialist | 48,000 | ISO 9001, ASME | 100 sqm | 6-8 weeks |

| Asian Volume Producer | 240,000 | ISO 9001 | 500 sqm | 10-12 weeks |

Leading Dutch manufacturers maintain 65% lower defect rates than industry averages. Premium certifications including NORSOK and ATEX compliance enable deployment in extreme environments like offshore platforms. Dutch exporters uniquely offer production verification at every manufacturing stage, with full material traceability.

Customization Capabilities for Specialized Applications

Holland wire mesh suppliers excel at tailoring solutions to precise technical requirements. Standard configuration options include:

Material Specifications

Stainless steel (304, 316, 316L), nickel alloys (Monel, Inconel), titanium, duplex steels with optional electropolishing, passivation or specialized coatings.

Structural Variations

Plain weave, twilled Dutch weave, reverse Dutch weave configurations, calibrated from 5 micron to 5mm pore sizes.

Form Factors

Disc filters, cylindrical cartridges, basket assemblies, filter presses, and modular panels with custom flanging, welding, and sealing options.

A specialized supplier recently engineered aerospace-grade titanium mesh filters capable of withstanding 2,500°F exhaust temperatures, demonstrating Dutch adaptability. Technical customization teams typically deliver prototypes within 7 business days.

Industry-Specific Application Solutions

Chemical Processing: Dutch mesh filters prevent catalyst loss in fluidized bed reactors, saving facilities approximately $380,000 annually in replacement costs. Specialized alloys resist hydrochloric acid exposure at 50% concentration levels.

Pharmaceutical Production: Precision sieving meshes with 1-15 micron calibration ensure 99.98% API purity compliance. Dutch manufacturers pioneered non-shedding weld techniques eliminating particulate contamination.

Water Treatment: Municipal plants utilizing Dutch mesh screens report 92% reduction in maintenance costs compared to wedge wire alternatives. Self-cleaning configurations process 55 million gallons daily with minimal downtime.

Mining Operations: Reinforced mesh panels withstand 180 PSI slurry pressure while trapping +200 mesh particles. Operations report 17% increase in mineral recovery rates after installation.

Strategic Selection Framework for Global Suppliers

Procurement specialists should evaluate Holland wire mesh exporters against these critical parameters:

Technical Validation

Demand certified material test reports covering chemical composition, mechanical properties, and ISO 21940 vibration resistance data.

Supply Chain Transparency

Require evidence of responsible sourcing practices and conflict-free material verification. Leading suppliers provide blockchain-tracked material journeys.

Performance Guarantees

Premium manufacturers offer 24-36 month performance warranties with failure analysis support. Verify service response times for technical consultations.

Logistical Capacity

Confirm export documentation expertise, customs clearance capabilities, and container optimization procedures to reduce freight costs by 18-25%.

Future-Forward Innovations from Dutch Wire Mesh Manufacturers

Dutch manufacturers are pioneering next-generation wire mesh technologies with 12-15% efficiency gains over current solutions. Sustainable production initiatives include:

• Closed-loop water recycling systems reducing consumption by 3.7 million liters annually

• Solar-powered manufacturing facilities with 92% renewable energy utilization

• Reclamation programs recovering 97% of scrap metal for reuse

Advancements like AI-calibrated weaving machines achieve dimensional tolerances of ±0.5 micron, while nano-enhanced coatings extend service life by 130%. Industry leaders are developing smart meshes with embedded sensors that monitor particle loading and flow characteristics in real-time.

The Holland wire mesh export market is projected to grow at 8.7% CAGR through 2030, driven by demand from energy transition technologies including hydrogen production and carbon capture systems that require ultra-fine separation capabilities beyond conventional filtration limits.

(holland wire mesh)

FAQS on holland wire mesh

Q: What is Holland Wire Mesh used for?

A: Holland Wire Mesh is versatile fencing for gardens, agriculture, and security. Its tight weave deters pests while allowing airflow. This galvanized steel solution offers durability against harsh weather.

Q: What certifications do Holland Wire Mesh manufacturers hold?

A: Reputable Holland Wire Mesh manufacturers provide ISO 9001, ASTM, or CE certified products. Certifications guarantee quality consistency and corrosion resistance. They also adhere to international safety standards during production.

Q: How do I choose reliable Holland Wire Mesh suppliers?

A: Verify supplier experience in galvanized wire exports and material test reports. Reliable Holland Wire Mesh suppliers offer custom specifications and bulk logistics support. Check third-party reviews for proven customer satisfaction.

Q: What shipping options do Holland Wire Mesh exporters offer?

A: Top Holland Wire Mesh exporters provide FOB, CIF, and EXW terms globally. Sea freight is standard for bulk rolls, while air options suit urgent orders. Export documentation and customs clearance support are typically included.

Q: Can Holland Wire Mesh manufacturers customize dimensions?

A: Yes, specialized Holland Wire Mesh manufacturers accommodate custom aperture sizes and roll lengths. They engineer solutions for specific load requirements or environmental conditions. Prototypes are often available for technical validation.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025