-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 09, 2025 20:40 Back to list

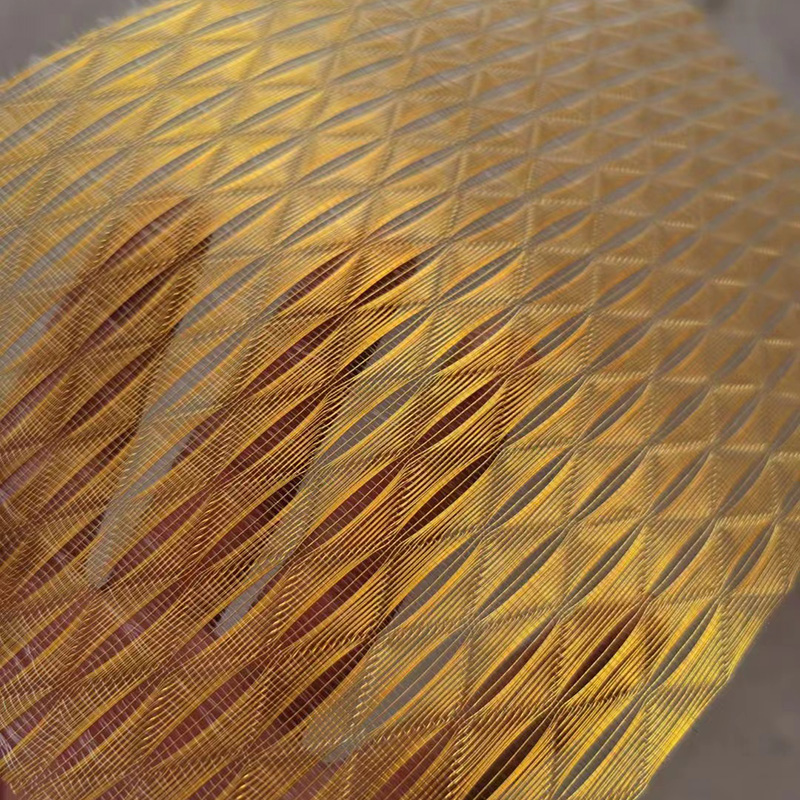

Premium Metal Mesh Fabric for Laminated Glass - Decorative & Durable

Introduction to Metal Mesh Fabric For Glass Laminated

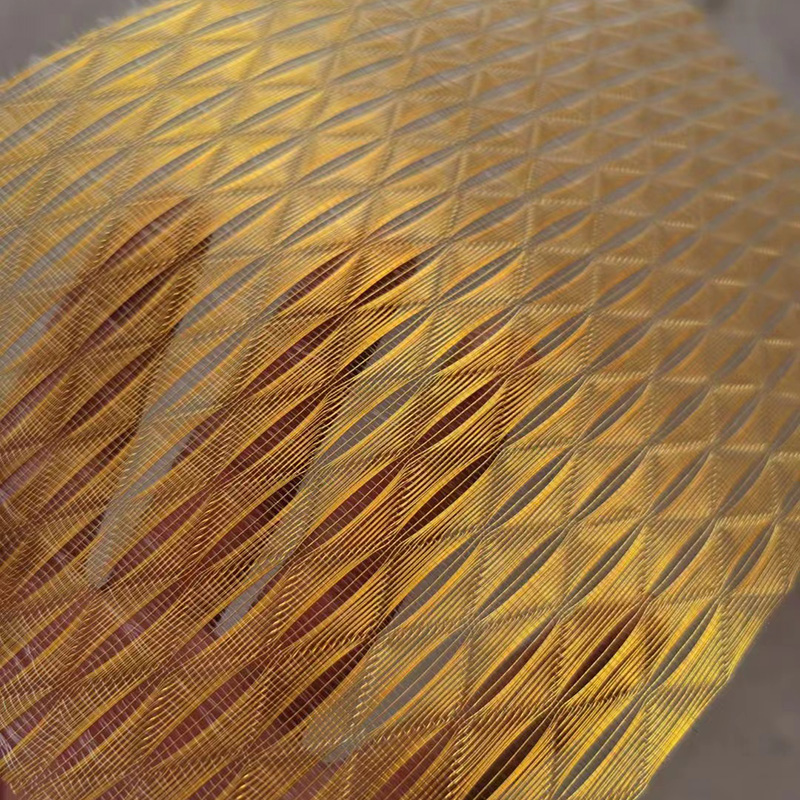

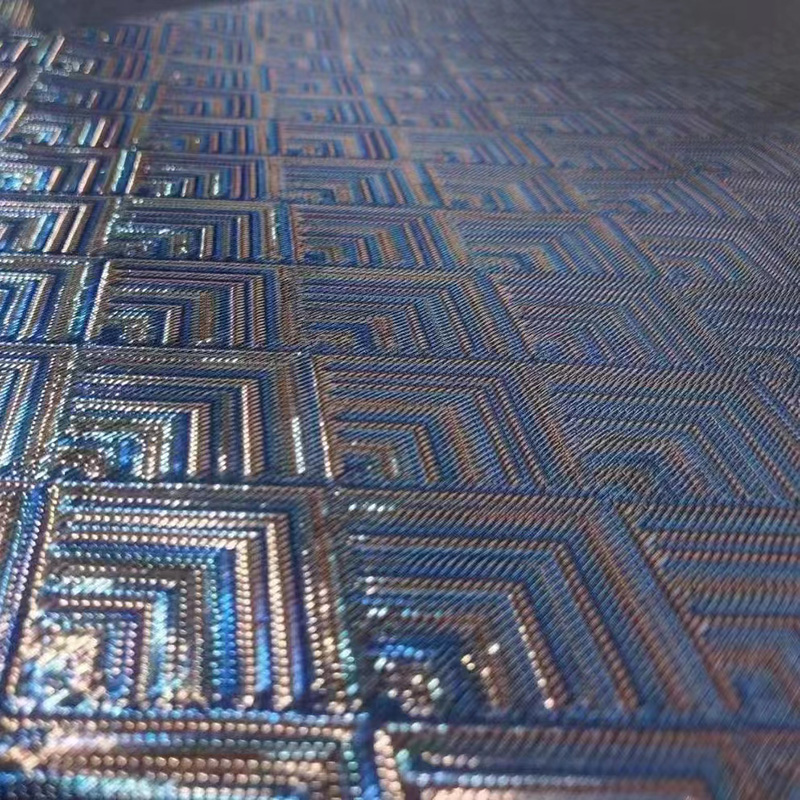

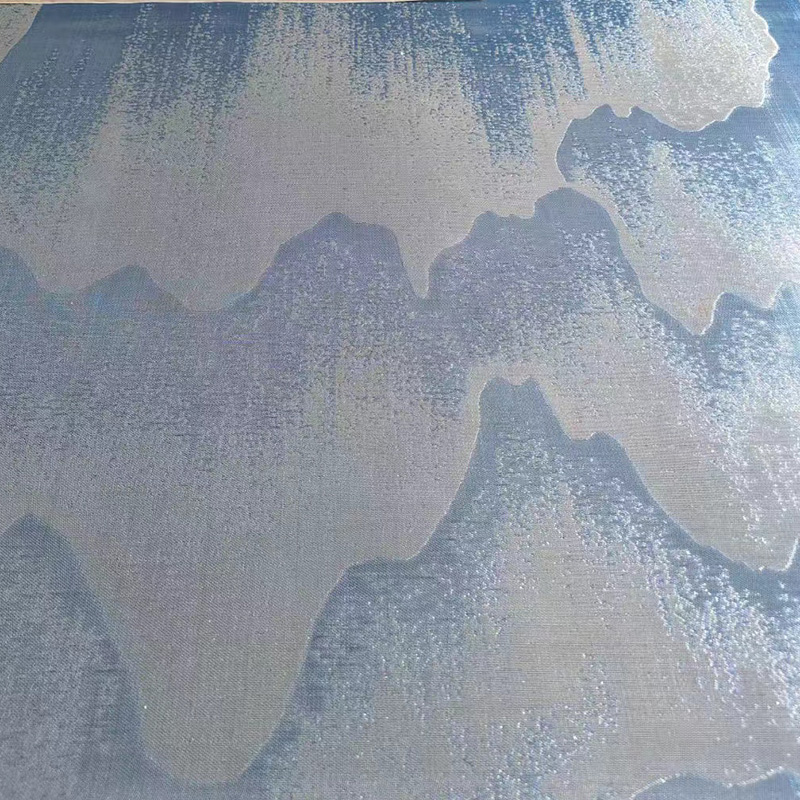

In modern architectural and interior design, the demand for innovative, high-performance materials continues to drive technological advancements. Among these, Metal Mesh Fabric For Glass Laminated stands out as a sophisticated solution, offering unparalleled aesthetic appeal, structural integrity, and functional versatility. This composite material, combining the strength and visual texture of woven metal with the safety and transparency of glass, provides architects, designers, and engineers with new possibilities for building envelopes, partitions, balustrades, and decorative elements.

The integration of metal mesh into laminated glass creates a product that is not only visually striking but also delivers enhanced security, solar control, and privacy. Its application spans across various sectors, from commercial skyscrapers and public infrastructure to high-end residential projects, reflecting a growing industry trend towards durable, sustainable, and aesthetically rich building materials. Understanding its manufacturing process, technical specifications, and diverse applications is crucial for leveraging its full potential in contemporary design.

Industry Trends and Market Dynamics

The market for advanced architectural materials, particularly those offering both aesthetic and performance benefits, is experiencing robust growth. Key drivers include increasing urbanization, stringent energy efficiency regulations, and a desire for unique, customizable building facades. The global laminated glass market, of which Metal Mesh Fabric For Glass Laminated is a premium segment, was valued at approximately USD 18 billion in 2022 and is projected to reach over USD 30 billion by 2030, growing at a CAGR of around 7%. This growth is fueled by demand from the automotive, building & construction, and solar energy sectors.

Technological advancements are leading to more intricate mesh patterns, enhanced material durability, and improved lamination techniques. There's a notable trend towards sustainable materials and processes, with manufacturers exploring recycled metals and low-energy production methods. Furthermore, the integration of smart technologies, such as electrochromic glass or embedded sensors, with mesh-laminated glass is an emerging frontier, promising dynamic control over light, privacy, and building performance. The emphasis on bespoke solutions for high-profile architectural projects also continues to drive innovation in design and manufacturing.

Detailed Manufacturing Process Flow

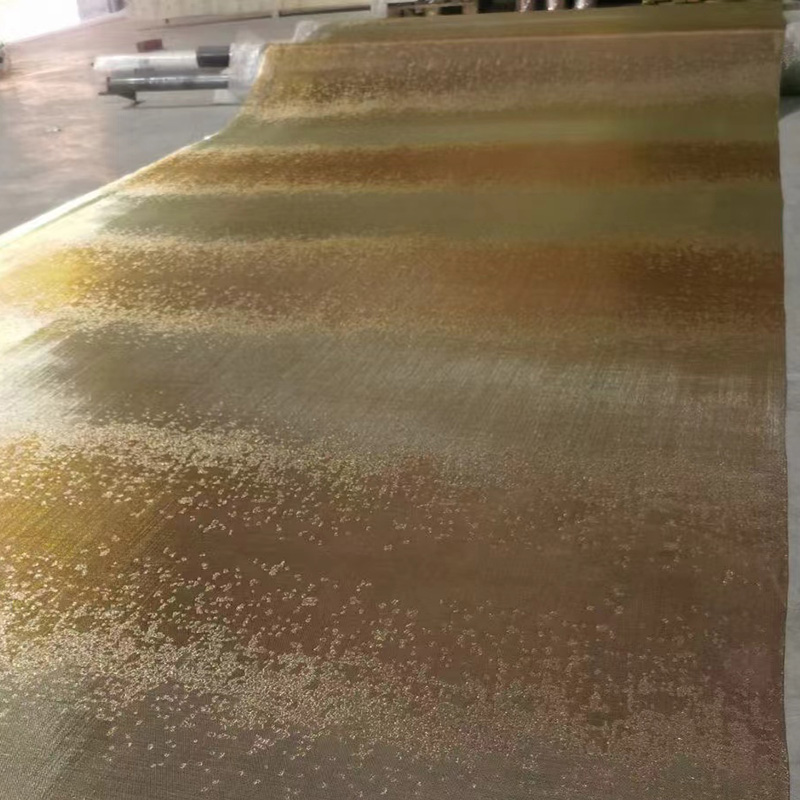

The creation of Metal Mesh Fabric For Glass Laminated is a meticulous process, combining precision engineering with advanced material science. It typically involves several critical stages to ensure the final product meets stringent quality and performance standards.

1. Material Selection and Preparation

- Metal Wires: High-grade stainless steel (e.g., AISI 304, 316, 316L) is predominantly used due to its excellent corrosion resistance, high tensile strength, and aesthetic appeal. Other materials like copper, bronze, or brass may be selected for specific visual effects. Wire diameters typically range from 0.1 mm to 2.0 mm, influencing mesh flexibility and transparency.

- Glass Panels: Annealed, heat-strengthened, or fully tempered glass, typically float glass, in various thicknesses (e.g., 3mm to 19mm) form the outer layers. Clarity, optical distortion, and surface quality are critical.

- Interlayer Films: Polyvinyl Butyral (PVB) or SentryGlas Plus (SGP) films are common. PVB offers excellent adhesion, impact resistance, and sound dampening. SGP provides superior structural strength, stiffness, and edge stability, particularly crucial for large panels or balustrades. Thicknesses range from 0.38mm to 2.28mm.

2. Mesh Fabrication (Weaving/Knitting)

- Weaving: Precision looms weave metal wires into desired patterns (e.g., plain weave, twill weave, Dutch weave, spiral weave). This process is critical for achieving specific open area percentages, light transmission, and aesthetic textures. CNC-controlled weaving machines ensure uniformity and reproducibility.

- Cleaning: The fabricated mesh undergoes a thorough cleaning process to remove oils, dust, and contaminants, ensuring optimal adhesion with the interlayer film.

3. Lamination Assembly (Clean Room Environment)

- Layering: In a controlled clean-room environment, the assembly stack is prepared: glass panel > interlayer film > metal mesh > interlayer film > glass panel. Meticulous alignment is crucial to prevent defects.

- Pre-pressing: The assembled stack is passed through a pre-pressing roller system or a vacuum bag to remove air pockets between layers, ensuring intimate contact. This is often done under controlled temperature.

4. Autoclaving

- Heat and Pressure: The pre-pressed assembly is transferred into an autoclave, where it undergoes a controlled cycle of heat (typically 120-150°C) and pressure (10-14 bar) for several hours. This process melts the interlayer film, causing it to flow and permanently bond the glass and mesh layers together, expelling any remaining air.

5. Finishing and Quality Control

- Edge Sealing/Finishing: Edges of the laminated panel may be ground, polished, or sealed to enhance aesthetics and prevent moisture ingress, particularly for outdoor applications.

- Testing Standards: Finished products undergo rigorous testing according to international standards such as ISO 12543 (Laminated glass and laminated safety glass), ANSI Z97.1 (Safety Glazing Materials), and EN 14449 (Glass in building – Laminated glass and laminated safety glass). Tests include impact resistance, heat stability, humidity resistance, and optical quality checks.

- Service Life: When manufactured to these standards and installed correctly, Metal Mesh Fabric For Glass Laminated products have an estimated service life exceeding 25-30 years, often matching the lifespan of the building itself, owing to the durability of stainless steel and the protective lamination.

Target Industries and Advantages:

- Target Industries: Architecture & Construction (facades, canopies, balustrades, partitions), Interior Design (decorative panels, flooring, ceilings), Retail & Hospitality (displays, feature walls), Transportation (marine, rail for decorative and protective elements).

- Advantages:

- Enhanced Safety and Security: The laminated structure prevents glass from shattering into dangerous shards upon impact, holding fragments in place.

- Aesthetic Versatility: Offers a unique visual texture, from subtle sheen to bold patterns, allowing for varied light reflection, transparency, and opacity.

- Solar Control & Energy Saving: Specific mesh patterns and materials can reduce solar heat gain and UV transmission, contributing to lower cooling costs and protecting interiors from fading.

- Corrosion Resistance: High-grade stainless steel ensures longevity and performance even in challenging environments (e.g., coastal areas, industrial zones).

- Structural Strength: The mesh provides additional rigidity and resistance to wind loads and impacts.

- Acoustic Dampening: The interlayer can help reduce sound transmission, improving interior comfort.

Technical Specifications and Parameters

The performance and suitability of Metal Mesh Fabric For Glass Laminated are defined by a range of technical parameters. These specifications are critical for engineers and designers to ensure the material meets project requirements.

Typical Product Specification Table:

| Parameter | Value Range / Specification |

|---|---|

| Metal Material | Stainless Steel (304, 316, 316L), Copper, Bronze, Brass |

| Wire Diameter | 0.1 mm - 2.0 mm (varies by mesh pattern) |

| Mesh Pattern | Plain, Twill, Dutch, Spiral, Decorative Weaves |

| Open Area Percentage | 20% - 70% (dependent on wire dia. & mesh opening) |

| Glass Type | Annealed, Heat-Strengthened, Tempered |

| Glass Thickness | Min 3+3mm to Max 19+19mm (total thickness including interlayer) |

| Interlayer Material | PVB (Polyvinyl Butyral), SGP (SentryGlas Plus) |

| Interlayer Thickness | 0.38mm, 0.76mm, 1.14mm, 1.52mm (PVB), 0.89mm, 1.52mm, 2.28mm (SGP) |

| Max Panel Size | Up to 3200mm x 8000mm (subject to transport & manufacturing limits) |

| Light Transmission | 10% - 80% (dependent on mesh open area and glass type) |

| UV Transmittance | <1% (with standard PVB/SGP) |

| U-Value (Thermal Transmittance) | Improved over monolithic glass (specific value depends on overall unit) |

| Shading Coefficient (SC) | 0.2 - 0.6 (highly variable based on mesh and glass) |

| Acoustic Reduction | 3-5 dB improvement over monolithic glass |

| Impact Resistance | Meets EN 12600 (Pendulum Test), ANSI Z97.1 |

These parameters are meticulously validated through internal testing and third-party certifications (e.g., ISO 9001 for quality management), ensuring the product's performance and compliance with relevant building codes and safety regulations. The choice of specific parameters depends on the intended application, environmental conditions, and desired aesthetic and functional outcomes.

Application Scenarios and Case Studies

The versatility of Metal Mesh Fabric For Glass Laminated allows its integration into a wide array of architectural and design applications. Its dual functionality—combining safety with sophisticated aesthetics—makes it a preferred choice for challenging and high-profile projects.

Typical Application Scenarios:

- Building Facades and Curtain Walls: Providing solar shading, privacy, and a distinctive visual texture that changes with light conditions, enhancing the building's exterior.

- Balustrades and Railings: Offering robust safety barriers with an elegant, contemporary look, often seen in staircases, balconies, and public spaces.

- Interior Partitions and Dividers: Creating semi-transparent separation within open-plan offices, retail spaces, or hospitality venues, allowing light penetration while offering subtle privacy.

- Canopies and Skylights: Delivering effective solar control and UV protection while maintaining an open, airy feel.

- Elevator Cabs and Lobbies: Decorative and protective cladding that adds a touch of luxury and durability.

- Art Installations and Signage: Custom mesh patterns and finishes can be used for unique artistic expressions or integrated branding.

- Flooring and Walkways: When specified with appropriate non-slip coatings, provides durable, light-transmitting surfaces.

Application Case Studies (Illustrative Examples):

Case Study 1: Corporate Headquarters Façade

A leading tech company implemented a double-skin façade system utilizing large panels of Metal Mesh Fabric For Glass Laminated with a fine stainless steel twill weave. The objective was to achieve optimal solar performance without compromising daylighting or exterior views. The mesh, specifically chosen with an open area of 35%, significantly reduced solar heat gain by 45% (SC from 0.75 to 0.41) compared to clear insulated glass, resulting in annual energy savings of approximately 18% for cooling. The façade also provided a distinct, shimmering appearance that reflected the company's innovative image. Our engineering team collaborated closely with the architects from concept to installation, ensuring precise fabrication and seamless integration.

Case Study 2: Museum Interior Balustrades

For a contemporary art museum, glass balustrades were required that offered maximum safety and a refined aesthetic. Metal mesh laminated glass panels (6mm clear tempered glass + 1.52mm SGP + bronze mesh + 6mm clear tempered glass) were selected. The bronze mesh provided a warm, artistic texture that complemented the museum's interior finishes, while the SGP interlayer ensured superior post-breakage integrity, exceeding safety standards for public access areas (meeting EN 12600 Class 1B1). This solution offered excellent light transmission, enhancing visibility across exhibits, while guaranteeing robust structural performance against accidental impact.

Vendor Comparison and Customized Solutions

Selecting the right vendor for Metal Mesh Fabric For Glass Laminated is crucial for ensuring product quality, project success, and long-term satisfaction. Beyond standard offerings, the capacity for customized solutions often differentiates leading suppliers.

Key Factors for Vendor Comparison:

| Factor | Leading Vendor (e.g., GalvanizedMeshProducts) | Standard Vendor |

|---|---|---|

| Product Range & Material Options | Extensive selection of metal alloys (SS 304/316/316L, Bronze, Copper), diverse weave patterns, wide glass/interlayer options. | Limited to standard stainless steel and basic weaves. |

| Customization Capabilities | Full bespoke design services, custom mesh patterns, precise color matching (PVD/coating), specialized glass treatments, large format capabilities. | Minimal customization, primarily standard sizes and finishes. |

| Quality Certifications & Testing | ISO 9001, CE, ANSI Z97.1, EN 12600. In-house R&D and advanced testing facilities. | Basic compliance, fewer independent certifications, limited test data. |

| Technical Support & Engineering | Dedicated project managers, CAD/BIM integration, structural analysis, specification assistance, installation guidance. | Basic product information, limited design support. |

| Lead Time & Logistics | Streamlined production, reliable global shipping, transparent lead time communication. | Potentially longer lead times, less predictable delivery. |

| Warranty & After-Sales | Comprehensive warranty (e.g., 10-15 years), responsive customer service, technical troubleshooting. | Limited warranty, less comprehensive support. |

Customized Solutions:

Leading manufacturers excel in providing tailor-made solutions for architects and designers. This includes:

- Unique Mesh Patterns: Developing proprietary weave structures or incorporating specific graphic elements into the metal mesh.

- Color and Finish Matching: Applying PVD coatings, electroplating, or other surface treatments to achieve specific colors (e.g., gold, black, custom bronze tones) or finishes (matte, polished) for the metal mesh, ensuring it harmonizes with the overall design palette.

- Specialized Glass Types: Lamination with low-iron glass for maximum clarity, etched or fritted glass for increased privacy, or even smart glass for dynamic optical properties.

- Integration with Building Systems: Providing guidance on mounting systems, edge treatments, and compatibility with other façade or interior elements.

- Performance Optimization: Engineering solutions to meet specific solar control (g-value, U-value), acoustic insulation, or security requirements.

Trustworthiness and Support

At GalvanizedMeshProducts, our commitment to reliability and customer satisfaction is paramount. We understand that investing in advanced materials like Metal Mesh Fabric For Glass Laminated requires assurances on product quality, delivery, and ongoing support.

Frequently Asked Questions (FAQ):

- Q: What is the maximum panel size you can produce?

A: We can manufacture panels up to 3.2 meters wide and 8 meters long, depending on specific mesh and glass combinations. Larger sizes may be feasible upon custom inquiry. - Q: Can the metal mesh be colored or treated?

A: Yes, we offer various finishing options including PVD coating for custom colors (e.g., gold, black, bronze, copper tones) and etching for unique surface textures. - Q: How does this product affect solar heat gain?

A: The integrated metal mesh significantly reduces solar heat gain and UV transmission, improving the building's energy efficiency. The exact performance depends on the mesh's open area and material. We provide detailed U-value, SHGC (Solar Heat Gain Coefficient), and VLT (Visible Light Transmittance) data for specific configurations. - Q: Is the product suitable for exterior applications?

A: Absolutely. Utilizing high-grade stainless steel (316/316L) and structural interlayers like SGP, our products are engineered for exceptional weather resistance and durability in outdoor environments, including coastal and high-humidity areas. - Q: What are the cleaning and maintenance requirements?

A: Standard glass cleaning procedures are generally sufficient. The laminated structure protects the mesh from environmental degradation, eliminating the need for separate mesh cleaning.

Lead Time and Fulfillment:

Our typical lead time for custom Metal Mesh Fabric For Glass Laminated projects ranges from 4 to 8 weeks, depending on the complexity of the mesh pattern, material availability, and order volume. For high-volume or specialized projects, lead times will be confirmed upon detailed quotation. We utilize robust packaging and collaborate with reputable global logistics partners to ensure secure and timely delivery to project sites worldwide.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive 10-year limited warranty against manufacturing defects and delamination, provided the product is installed and maintained according to industry best practices and our guidelines. Specific warranty details are provided with each project contract.

Customer Support Information:

Our dedicated team of technical sales engineers and project managers is available to assist you at every stage of your project, from initial concept and material selection to specification development and post-installation support. For inquiries, technical assistance, or to request a quote, please visit our website at galvanizedmeshproducts.com or contact us directly via the contact information provided there. We are committed to providing prompt and expert advice to ensure your project's success.

Conclusion

The integration of metal mesh within laminated glass represents a significant advancement in architectural materials, offering a compelling blend of aesthetic sophistication, structural resilience, and multifaceted performance benefits. As the construction industry continues to seek innovative solutions for energy efficiency, security, and unique design expressions, Metal Mesh Fabric For Glass Laminated stands as a testament to the potential of composite materials. Its proven track record in diverse applications, coupled with ongoing advancements in manufacturing and customization, positions it as a leading choice for architects and designers worldwide who are pushing the boundaries of modern building design.

References

- ISO 12543-1:2011 Glass in building — Laminated glass and laminated safety glass. International Organization for Standardization.

- ANSI Z97.1-2015 Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test. American National Standards Institute.

- EN 14449:2005 Glass in building – Laminated glass and laminated safety glass – Evaluation of conformity/Product standard. European Committee for Standardization.

- "Global Laminated Glass Market: Industry Analysis & Forecast (2023-2030)." Maximize Market Research, October 2023.

- "Sustainable Building Materials: A Comprehensive Review." Journal of Cleaner Production, Elsevier, 2022.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025