-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 10, 2025 09:00 Back to list

Rib Lath for Superior Stucco & Plaster Reinforcement

Industry Trends and the Role of Rib Lath in Modern Construction

The global construction industry is continually evolving, driven by demands for increased structural integrity, improved material efficiency, and accelerated project timelines. Within this dynamic landscape, specialized building materials play a critical role in meeting these stringent requirements. One such indispensable material is Rib Lath, a high-performance expanded metal sheet primarily used as a plaster base and in concrete formwork. Recent trends indicate a growing preference for materials that offer both structural enhancement and ease of application, a niche where Rib Lath excels. The push for sustainable and durable construction practices further solidifies its position, as its robust design contributes to the longevity and resilience of built structures.

Technological advancements in manufacturing have led to the production of Rib Lath with superior tensile strength and corrosion resistance, expanding its utility beyond traditional applications. Innovations in material science, such as advanced galvanization techniques and the use of stainless steel variants, have significantly extended the service life of Rib Lath, making it suitable for aggressive environments. This evolution aligns perfectly with the industry's focus on reducing maintenance costs and ensuring long-term asset performance. As urban development continues globally, the demand for efficient and reliable construction materials like Rib Lath is projected to rise, particularly in regions experiencing rapid infrastructure expansion.

Manufacturing Process Flow of Rib Lath

The production of Rib Lath involves a precise, multi-stage manufacturing process designed to achieve its characteristic rigidity and excellent plaster-keying properties. Understanding this process is key to appreciating the material's structural integrity and performance capabilities.

Materials and Initial Preparation:

- ➤ Primarily, high-quality cold-rolled steel coils are used. For enhanced corrosion resistance, these coils are often pre-galvanized (hot-dip galvanized or electro-galvanized) in accordance with standards like ASTM A653/A653M for zinc-coated (galvanized) steel or ASTM A240 for stainless steel grades (e.g., 304, 316) for extreme environments.

- ➤ The steel coils are precisely slit to the required width, ensuring consistent raw material dimensions for the subsequent stages.

Expansion and Rib Forming:

- ➤ The slit steel sheets undergo a precision stamping and expanding process. Specialized machinery with cutting dies creates a series of parallel slits and stretches the metal, forming the distinctive diamond-shaped mesh pattern. This expansion increases the surface area and creates the rough texture essential for plaster adhesion.

- ➤ Simultaneously, or in a subsequent inline process, longitudinal ribs are cold-formed into the expanded metal. These ribs, typically V-shaped, provide the inherent stiffness and rigidity that define Rib Lath. The number and depth of these ribs vary based on the specific product type (e.g., High Rib Lath, Flat Rib Lath) and desired structural performance.

Finishing and Quality Control:

- ➤ After forming, the continuous mesh is cut to standard sheet lengths. Edges are often trimmed to remove burrs and ensure safe handling.

- ➤ Testing Standards: Each batch undergoes rigorous quality control. This includes dimensional checks (width, length, rib height, mesh opening size), material thickness verification, and visual inspection for defects. Manufacturers typically adhere to international quality management standards like ISO 9001 and product-specific standards such as ASTM C847 (Standard Specification for Metal Lath) or regional building codes.

- ➤ Service Life: When properly installed and protected within building envelopes, galvanized Rib Lath can have a service life exceeding 50 years. In highly corrosive environments, stainless steel variants offer superior longevity, potentially surpassing 75-100 years.

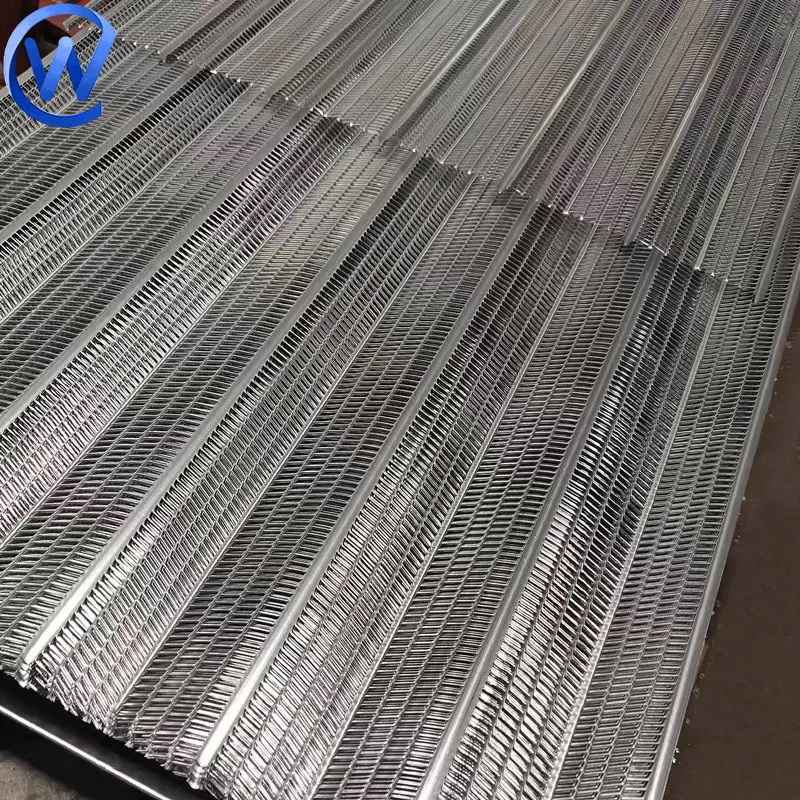

Precision manufacturing ensures consistent quality of Rib Lath.

Target Industries and Advantages:

Rib Lath is extensively utilized across various industries due to its inherent advantages:

- ✓ Building & Construction: Essential for internal and external plastering, stucco work, and as a permanent formwork for concrete slabs, beams, and columns, offering superior bond and crack resistance.

- ✓ Civil Engineering: Used in tunneling, bridge construction, and retaining walls, where its rigidity aids in structural support and concrete retention.

- ✓ Mining: Provides stability for shotcrete applications in mine shafts and underground excavations.

- ✓ Petrochemical & Industrial: Stainless steel versions are used in corrosive environments for fireproofing and insulation cladding, demonstrating excellent corrosion resistance against chemical exposure.

Technical Specifications and Parameters of Rib Lath

Selecting the appropriate Rib Lath for a project requires a thorough understanding of its technical specifications. These parameters dictate its suitability for various structural loads, plaster types, and environmental conditions. The table below details typical specifications for commonly available types.

Various types of Rib Lath offer distinct technical advantages.

Rib Lath Product Specification Table

| Characteristic | Metric Unit (Typical) | Imperial Unit (Typical) | Notes |

|---|---|---|---|

| Material | Galvanized Steel (G60/G90), Stainless Steel (304/316) | Galvanized Steel, Stainless Steel | Coating weight per ASTM A653 |

| Thickness / Gauge | 0.30mm - 0.50mm | 27 ga - 25 ga | Thicker gauges for heavier applications |

| Rib Height (Typical) | 4mm - 12mm | 0.16 in - 0.47 in | Higher ribs provide greater rigidity |

| Strand Width | Approx. 1.0mm - 2.0mm | Approx. 0.04 in - 0.08 in | Affects mesh strength and plaster key |

| Sheet Width | 450mm, 610mm | 18 in, 24 in | Standard panel widths |

| Sheet Length | 2200mm, 2440mm, 2500mm | 7 ft, 8 ft, 8.2 ft | Custom lengths available |

| Weight per Sheet (e.g., 27ga, 610x2440mm) | Approx. 2.5 kg - 3.5 kg | Approx. 5.5 lbs - 7.7 lbs | Varies by gauge and dimensions |

| Mesh Opening | 10x20mm to 15x30mm (approx.) | Varies | Optimal for mechanical keying of plaster/stucco |

| Tensile Strength (Base Material) | Typical 275-400 MPa | Typical 40-58 ksi | Per ASTM A653 for galvanized steel |

These specifications allow engineers and procurement specialists to precisely match the performance characteristics of Rib Lath with project requirements, ensuring structural integrity and long-term durability.

Application Scenarios and Technical Advantages

The versatility of Rib Lath allows its application across a broad spectrum of construction and industrial projects, each benefiting from its unique technical advantages.

Rib Lath excels in demanding construction applications, enhancing plaster and concrete performance.

Plaster and Stucco Reinforcement:

- ✓ Enhanced Mechanical Key: The expanded mesh and prominent ribs create an exceptional mechanical key for plaster, render, and stucco, ensuring superior bond strength and significantly reducing the risk of cracking and delamination. This is particularly crucial for exterior wall systems subject to thermal expansion and contraction.

- ✓ Consistent Thickness: The inherent rigidity provided by the ribs helps maintain a consistent plaster thickness across the surface, contributing to a flatter, more uniform finish and reducing material waste.

Permanent Formwork for Concrete:

- ✓ Reduced Formwork Removal: When used as permanent formwork, especially in concrete joints, soffits, and complex shapes, Rib Lath eliminates the need for stripping conventional formwork. This accelerates construction schedules and reduces labor costs.

- ✓ Excellent Concrete Retention: The mesh structure allows excess water to drain out while retaining concrete fines, promoting denser concrete and eliminating cold joints. This improves the structural integrity of the concrete element.

- ✓ Fire Resistance: The metallic composition contributes to fire resistance, which is critical for structural elements in commercial and industrial buildings.

Corrosion Resistance and Energy Efficiency:

- ✓ Durable in Harsh Environments: Galvanized Rib Lath provides a sacrificial zinc coating that protects the steel substrate from rust and corrosion, making it suitable for exterior applications and areas with moderate humidity. Stainless steel variants offer superior corrosion resistance in marine, chemical, and highly aggressive industrial environments.

- ✓ Facilitates Insulation: In cavity wall constructions or insulated render systems, Rib Lath can secure insulation boards and act as a robust base for exterior finishes, contributing to enhanced thermal performance and energy saving in buildings by minimizing thermal bridging and air infiltration.

Vendor Comparison and Customized Solutions

The market for Rib Lath is diverse, with various manufacturers offering products that differ in quality, adherence to standards, and customization capabilities. When selecting a vendor, it's crucial to evaluate several factors beyond just price.

Reliable vendors provide consistent quality and support for Rib Lath solutions.

Key Factors for Vendor Comparison:

- ★ Certifications & Compliance: Look for manufacturers adhering to international standards such as ISO 9001 for quality management, and product-specific standards like ASTM C847. Certifications from recognized bodies provide assurance of consistent quality and performance.

- ★ Material Quality: Verify the grade and coating of steel used. For galvanized Rib Lath, inquire about the zinc coating weight (e.g., G60, G90) to ensure adequate corrosion protection for your specific application.

- ★ Manufacturing Precision: Consistent rib height, strand width, and mesh pattern are indicators of a quality product. Inconsistencies can lead to uneven plaster application or reduced structural integrity.

- ★ Logistics & Lead Times: A reliable vendor will have efficient supply chain management, offering reasonable lead times and flexible delivery options to minimize project delays.

- ★ Technical Support & After-Sales Service: Access to expert technical guidance, installation support, and responsive customer service can be invaluable, especially for complex projects.

Customized Solutions:

While standard Rib Lath dimensions are widely available, many projects benefit from customized solutions. A reputable manufacturer should offer:

- ● Tailored Dimensions: Production of sheets in non-standard widths or lengths to reduce waste and optimize installation time for specific architectural designs or structural requirements.

- ● Material Options: Offering different steel grades (e.g., higher strength alloys) or coating types (e.g., enhanced zinc-aluminum coatings) for specialized environmental conditions.

- ● Rib Configuration: Adjustments to rib height or spacing to meet unique plastering or concrete bonding challenges, ensuring optimal performance for bespoke applications.

- ● Pre-fabricated Elements: Some advanced manufacturers can provide pre-cut or pre-formed Rib Lath elements for intricate architectural features, further streamlining on-site work.

Partnering with a vendor capable of providing customized solutions ensures that the Rib Lath integrates seamlessly into complex project designs, enhancing efficiency and structural performance.

Application Case Studies & Customer Experience

Real-world applications highlight the tangible benefits of using Rib Lath. Our commitment to quality and client success is reflected in numerous projects, ranging from large-scale infrastructure to specialized architectural finishes.

Rib Lath deployed in a large-scale commercial building project.

Case Study 1: High-Rise Residential Tower – Façade Reinforcement

- ‣ Challenge: A 40-story residential tower in a coastal city required a durable, crack-resistant stucco façade that could withstand significant wind loads and salt exposure. Traditional lathing methods showed potential for cracking over time due to building movement and environmental factors.

- ‣ Solution: Galvanized Rib Lath (G90 coating, 3.4 lbs/sy) was specified and installed as the primary plaster base. Its inherent rigidity and enhanced mechanical keying properties significantly improved the bond between the substrate and the multi-coat stucco system.

- ‣ Outcome: After 5 years, the façade shows no signs of cracking or delamination, exceeding the client's expectations for durability and aesthetic longevity. The project manager noted a 15% reduction in plastering time due to the ease of application over the rigid lath.

Case Study 2: Underground Tunnel Project – Shotcrete Support

- ‣ Challenge: A critical section of a metropolitan underground tunnel required immediate and robust support for shotcrete application to stabilize rock faces and ensure worker safety. The irregular rock contours presented difficulties in achieving uniform shotcrete thickness.

- ‣ Solution: Customized, heavy-gauge galvanized Rib Lath with extra-high ribs was supplied. Its inherent stiffness allowed it to be contoured to the rock face, providing a stable formwork and rebar support for the wet shotcrete application.

- ‣ Outcome: The project achieved a consistent and strong shotcrete layer, significantly improving ground support and accelerating the tunneling process by 20%. The engineers praised the lath's adaptability and strength under demanding conditions.

Trustworthiness, Lead Times, Warranty, and Support

Building trust in B2B relationships is paramount. Our commitment extends beyond delivering high-quality Rib Lath; it encompasses transparent processes, robust support, and clear commitments.

Reliable packaging ensures Rib Lath arrives in perfect condition.

Frequently Asked Questions (FAQ):

Q: What is the primary difference between Rib Lath and expanded metal lath?

A: Rib Lath features stiffening ribs running longitudinally, providing significantly greater rigidity and strength compared to standard flat expanded metal lath. This makes it ideal for applications requiring enhanced structural support, such as ceiling plastering or concrete formwork, without sagging.

Q: Can Rib Lath be used outdoors in corrosive environments?

A: Yes, galvanized Rib Lath offers good corrosion resistance for most outdoor applications. For highly corrosive environments like marine or industrial chemical zones, we recommend using stainless steel Rib Lath (e.g., Grade 316) for superior longevity and performance.

Q: What are the typical lead times for large orders?

A: Standard lead times for common dimensions of Rib Lath are typically 2-4 weeks, depending on order volume and current production schedules. For customized orders or very large quantities, lead times may extend to 4-6 weeks. We work closely with our clients to establish realistic timelines and offer expedited production options where feasible.

Lead Time & Fulfillment Details:

- ► Order Processing: Orders are processed within 24-48 hours of confirmation.

- ► Manufacturing & Quality Check: Production typically takes 1-3 weeks, followed by stringent quality assurance protocols to ensure compliance with specifications.

- ► Shipping: We partner with reliable logistics providers to offer various shipping options (sea freight, air cargo, land transport) tailored to project deadlines and budget. Real-time tracking is provided.

Warranty Commitments:

Our Rib Lath products are backed by a comprehensive warranty against manufacturing defects and material failure under normal use and installation. Specific warranty periods vary by product type and material, typically ranging from 5 to 10 years. Detailed warranty terms are provided with each purchase agreement and are fully compliant with industry standards.

Customer Support Information:

- ✆ Technical Assistance: Our team of experienced engineers is available for technical consultations, product selection guidance, and installation best practices. Contact us via phone or email during business hours.

- ✉ Sales & Inquiries: For quotes, custom orders, or general sales inquiries, please reach out to our dedicated sales department.

- 📞 After-Sales Support: Post-purchase support includes assistance with delivery issues, product concerns, and warranty claims. Your satisfaction is our priority.

Our Rib Lath is packaged securely for transport and delivery.

Conclusion

Rib Lath stands as a foundational material in modern construction, offering unparalleled rigidity, superior plaster and concrete adhesion, and adaptability across diverse applications. Its consistent performance, backed by rigorous manufacturing processes and adherence to international standards, makes it an indispensable choice for engineers and construction professionals seeking durable, efficient, and cost-effective solutions. From reinforcing delicate plasterwork in architectural marvels to providing robust support in demanding civil engineering projects, the technical advantages of Rib Lath contribute significantly to the longevity and structural integrity of built environments worldwide. As the industry continues to innovate, the evolution of Rib Lath, including specialized material options and customized solutions, ensures its continued relevance and essential role in future construction paradigms.

References

- ASTM International. (2018). ASTM C847/C847M-18, Standard Specification for Metal Lath. West Conshohocken, PA: ASTM International.

- ASTM International. (2020). ASTM A653/A653M-20, Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. West Conshohocken, PA: ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems — Requirements. Geneva, Switzerland: ISO.

- Building Material & Construction Market Research Reports. (2023). Global Expanded Metal Lath Market Analysis. Retrieved from industryresearch.com.

- Portland Cement Association (PCA). (2019). Guide to Stucco Application. Skokie, IL: PCA.

- U.S. Department of Energy. (2020). Energy Efficiency in Commercial Buildings. Retrieved from energy.gov.

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025