-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 24, 2024 02:04 Back to list

Reliable Suppliers of Galvanized Square Woven Wire Mesh for Various Applications and Industries

Understanding Galvanized Square Woven Wire Mesh and Its Suppliers

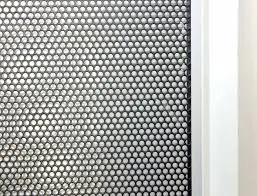

Galvanized square woven wire mesh is an essential material in various industries, known for its durability, corrosion resistance, and versatility. This type of mesh is created by weaving together wire strands in a square pattern, which provides strength and stability for a range of applications, from construction to agriculture. The addition of a galvanized coating enhances the wire’s resilience against rust and wear, making it an ideal choice for outdoor and demanding environments.

Characteristics of Galvanized Square Woven Wire Mesh

The primary characteristic that sets galvanized wire mesh apart from other types of mesh is the zinc coating applied to the steel wire. This galvanization process can occur through two methods hot-dip galvanization and electro-galvanization. Hot-dip galvanization involves immersing the wire in molten zinc, resulting in a thicker coating that offers superior protection. On the other hand, electro-galvanization applies a thinner layer using electrochemical processes, which may be more suitable for certain applications where extreme exposure to the elements is not a concern.

Galvanized square woven wire mesh is available in various wire diameters, mesh openings, and roll sizes, making it customizable to meet specific project requirements. Common applications of this mesh include fencing, filtration screens, machine guards, and even as reinforcement for concrete.

Applications Across Industries

The versatility of galvanized square woven wire mesh means it can be found in numerous sectors - Construction Used as temporary fencing, concrete reinforcement, and scaffolding safety nets. It provides essential structural support and safety features on construction sites. - Agriculture Farmers utilize this mesh for building animal enclosures, crop protection, and as trellising systems. Its robust nature ensures longevity even in harsh weather conditions. - Industrial In manufacturing, it serves as a protective barrier, machine guarding, and equipment enclosures. Its ability to withstand tough environments is a significant advantage for industrial applications. - Filtration The mesh is perfect for filtration purposes, be it water treatment or air filtration systems, where durability and precision are imperative.

Choosing the Right Supplier

galvanized square woven wire mesh suppliers

When looking for suppliers of galvanized square woven wire mesh, it's essential to consider a few critical factors to ensure quality and reliability.

1. Quality Assurance A reputable supplier should meet industry standards for durability and performance. Requesting certifications or compliance with ANSI or ASTM standards can be a good start.

2. Customization Options Different projects require different specifications. A supplier that offers customization in terms of wire diameter, mesh size, and roll length can better cater to your specific needs.

3. Customer Service Reliable suppliers should have excellent customer service to assist in choosing the right products and addressing any concerns during the ordering process.

4. Experience and Reputation Look for suppliers with a proven track record in the industry. Check customer reviews, and case studies, or ask for referrals to gauge their reputation and reliability.

5. Pricing and Availability While price is an important consideration, the cheapest option is not always the best. Balance cost with quality to find a supplier that offers value. Also, ensure they can meet your required delivery timelines.

Conclusion

Galvanized square woven wire mesh is a critical material across various industries due to its strength, durability, and flexibility. Partnering with the right suppliers ensures access to high-quality products tailored to your specific needs. As you explore options, prioritize quality, customer service, and the ability to meet your unique requirements to ensure you make an informed choice. With the right materials and partners, your projects can achieve both efficiency and longevity.

-

Chicken Wire Fence Suppliers Durable & Affordable Poultry Solutions

NewsMay.19,2025

-

Mesh Screen Panels High-Quality Exporter & Manufacturer Solutions

NewsMay.19,2025

-

3D Panel Fence for Cattle Farms Durable & Customizable Solutions

NewsMay.19,2025

-

Barbed Wire Mesh High-Security Razor Fencing Solutions by Experts

NewsMay.18,2025

-

Durable Deer Netting Solutions Reliable Manufacturer & Supplier

NewsMay.18,2025

-

Durable 1x1 Welded Wire Mesh Panels Custom & Export Solutions

NewsMay.18,2025