-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 24, 2025 16:50 volver a la lista

Secure & Durable Chain Link Fence | Galvanized & PVC Options

Understanding the Cerca de alambre: A B2B Perspective on Industrial Perimeter Security

The chain link fence, often referred to as a cyclone fence or diamond mesh fence, stands as a cornerstone in perimeter security and demarcation across countless industrial and commercial sectors. Its ubiquitous presence is a testament to its unparalleled combination of cost-effectiveness, durability, and adaptability. From securing critical infrastructure in petrochemical plants to delineating boundaries in public works, the chain link fence offers a robust yet visually unintrusive solution. This comprehensive guide delves into the technical intricacies, manufacturing excellence, diverse applications, and strategic considerations for B2B decision-makers seeking optimal fencing solutions.

Our focus extends beyond mere product description to encompass the full lifecycle of these essential security assets, emphasizing material science, manufacturing precision, and long-term performance metrics crucial for industrial procurement. We will explore the advantages of various finishes, including galvanized chain link fence and PVC coated chain link fence, and provide insights into wholesale chain link fence procurement for large-scale projects.

Manufacturing Excellence: The Process Behind the Chain Link Fence

The production of a high-quality chain link fence involves a meticulously controlled process, starting from raw material selection to final quality assurance. Understanding this process is vital for appreciating the product's inherent strengths and selecting the right specifications for demanding industrial environments.

Materials and Wire Drawing

The foundation of any durable chain link fence is the wire itself. Typically, this begins with high-grade steel rod, often low-carbon steel, which undergoes a cold drawing process to achieve the desired wire gauge. Common wire diameters range from 12.5 gauge (2.29mm) for light residential use to 6 gauge (4.11mm) for heavy-duty industrial security. The tensile strength of the drawn wire is critical, often specified between 60,000 to 80,000 PSI (415 to 550 MPa) to ensure resilience against impact and cutting.

Galvanization and Coating

- Hot-Dip Galvanization: This is the most prevalent and effective corrosion protection method. After wire drawing, the steel wire is immersed in a bath of molten zinc. The metallurgical bond formed between the zinc and steel provides a sacrificial barrier, protecting the steel from rust even if the coating is scratched. Coating weights are specified by ASTM A116 (e.g., Class 1, 2, or 3, with Class 3 offering maximum protection at 1.20 oz/ft² or 366 g/m²). This results in a robust galvanized chain link fence wire mesh.

- Electro-Galvanization: A thinner zinc coating is applied electrolytically. While cost-effective, it offers less corrosion resistance than hot-dip galvanization and is generally recommended for less demanding applications.

- PVC Coating: For enhanced aesthetics, superior corrosion resistance, and protection against harsh chemicals or extreme weather, PVC coated chain link fence wire is produced. This involves extruding a layer of polyvinyl chloride over galvanized wire. PVC coatings are available in various colors and thicknesses, providing an additional barrier against environmental degradation and extending service life significantly.

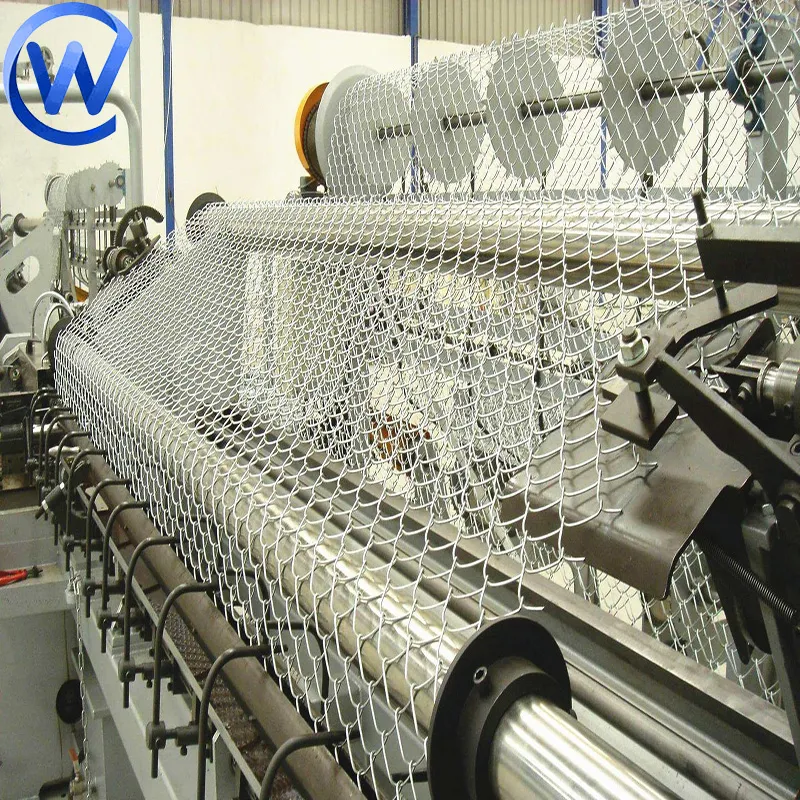

Weaving Process

Automated weaving machines take the treated wire (galvanized or PVC coated) and create the distinctive diamond pattern. Coiled wires are fed into the machine, which automatically twists and interlocks them to form the mesh. The mesh size, or diamond size, is a crucial specification, dictating the aperture of the mesh. Common mesh sizes include 2-inch (50mm) and 2.375-inch (60mm) for standard security, with smaller mesh sizes (e.g., 1.75-inch or 45mm) available for higher security or animal containment. The selvage (edge finish) is either "knuckled" (bent over) for safety or "twisted" (barbed) for enhanced security at the top and bottom of the fabric.

Quality Control and Testing Standards

Throughout the manufacturing process, stringent quality control measures are implemented. Key testing standards include:

- ASTM A392: Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric. This covers general requirements, wire sizes, mesh sizes, and zinc coating weights.

- ASTM F668: Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric. This details coating thickness, adhesion, and resistance to environmental factors.

- ISO 9001: Certification for quality management systems ensures consistent product quality and process adherence.

- Tensile Strength Testing: Ensures the wire meets specified breaking strength requirements.

- Coating Thickness Measurement: Verifies the galvanization or PVC coating weight/thickness using methods like X-ray fluorescence (XRF) or magnetic induction.

Figure 1: Automated weaving of chain link fence fabric.

Technical Specifications and Performance Parameters

Selecting the appropriate chain link fence requires a thorough understanding of its technical specifications. These parameters directly influence performance, durability, and suitability for specific applications.

Key Specifications for Industrial Applications

| Parameter | Typical Industrial Range | ASTM Standard | Impact on Performance |

|---|---|---|---|

| Calibre del cable (diámetro) | 9 Ga (3.76mm) - 6 Ga (4.11mm) | A392 / F668 | Thicker wire = greater strength, impact resistance, and longevity. Critical for security. |

| Mesh Size (Diamond) | 2" (50mm) - 2.375" (60mm) for standard; 1.75" (45mm) for high-security | A392 / F668 | Smaller mesh prevents climbing and deters intrusion of small objects/animals. |

| Zinc Coating Weight | Class 2 (0.60 oz/ft²) or Class 3 (1.20 oz/ft²) | A116 / A90 | Higher coating weight significantly extends corrosion resistance and service life for galvanized chain link fence. |

| PVC Coating Thickness | Min. 0.006" (0.15mm) over galvanized wire | F668 | Adds UV resistance, chemical resistance, and enhanced aesthetics to PVC coated chain link fence. |

| Fence Height | 6 ft (1.8m) to 12 ft (3.6m) typically; higher for specialized security | N/A | Determines the physical barrier and level of intrusion deterrence. Often combined with barbed wire. |

Service Life and Environmental Factors

The projected service life of a chain link fence varies significantly with material quality and environmental conditions. A standard galvanized fence (Class 2) typically lasts 15-20 years in moderate climates. A Class 3 galvanized chain link fence can exceed 25 years. PVC coated chain link fence often offers superior longevity, especially in coastal areas or industrial zones with chemical exposure, extending service life to 20-30+ years due to the added protective layer. Regular inspection and minimal maintenance can further prolong the effective lifespan, underscoring the long-term value proposition for wholesale chain link fence investments.

Figure 2: Close-up of galvanized chain link fence wire mesh showing mesh integrity.

Industry Trends and Innovation in Chain Link Fence Systems

While the fundamental design of the chain link fence remains consistent, continuous innovation in materials and integration with modern security technologies are shaping its evolution. Current trends focus on enhancing security, extending service life, and improving aesthetic integration.

Enhanced Coatings and Materials

Beyond traditional galvanization and PVC, hybrid coatings incorporating zinc-aluminum alloys (e.g., Galfan or Bezinal) are gaining traction. These offer superior corrosion resistance, often exceeding standard galvanization by 2-3 times in accelerated salt spray tests, translating to even longer service life and reduced maintenance for chain link fence wire roll products.

Smart Fencing Integration

The modern industrial chain link fence is increasingly integrated with advanced security systems. This includes:

- Fiber Optic Sensors: Embedded or attached to the fence fabric, these detect vibrations caused by climbing, cutting, or tampering, providing instant alerts.

- Perimeter Intrusion Detection Systems (PIDS): Using seismic, microwave, or infrared technologies, PIDS can be deployed alongside a cyclone fence to create virtual exclusion zones, minimizing false alarms while maximizing detection accuracy.

- CCTV and Access Control: Seamless integration with surveillance cameras and controlled access points transforms a basic chain link fence into a smart, multi-layered security barrier.

Sustainability and Recycled Content

With growing emphasis on environmental responsibility, manufacturers are exploring the use of recycled steel content in wire production and developing more environmentally friendly coating processes. This aligns with corporate sustainability goals for large industrial users procuring wholesale chain link fence solutions.

Application Scenarios and Technical Advantages

The versatility of the chain link fence allows it to serve a vast array of target industries and application scenarios, each benefiting from its specific technical advantages.

Target Industries and Typical Use Cases:

- Petrochemical & Energy: Securing refineries, power plants, and pipeline perimeters against unauthorized access. Galvanized chain link fence with barbed wire is common due to its robust corrosion resistance and high security.

- Metallurgy & Mining: Fencing ore processing sites, equipment storage yards, and tailings ponds. The open mesh design allows for visual monitoring while providing a physical barrier.

- Water Supply & Drainage: Protecting water treatment facilities, reservoirs, and pumping stations. PVC coated chain link fence is often preferred for its resistance to moisture and chemical environments.

- Transportation & Logistics: Enclosing airports, railway lines, ports, and warehousing complexes. Its ease of installation and ability to conform to varied terrains make it ideal for extensive perimeters.

- Telecommunications: Securing cellular towers, data centers, and equipment enclosures. Often installed with privacy slats for visual obstruction.

- Government & Municipal: Fencing schools, parks, military bases, and correctional facilities. High-security configurations of diamond mesh fence are prevalent.

Technical Advantages:

- Corrosion Resistance: Particularly for galvanized chain link fence and PVC coated variants, superior resistance to rust and degradation ensures long-term integrity in harsh industrial settings. This is a critical advantage, significantly reducing lifecycle costs.

- Durability & Strength: The woven steel wire construction provides high tensile strength, making it difficult to cut or breach, especially with heavier gauges.

- Cost-Effectiveness: Compared to other high-security fencing options, the initial outlay and ongoing maintenance costs for a chain link fence are significantly lower, offering an excellent return on investment for large-scale deployments.

- Adaptability: Easily installed on varied terrains, including slopes and uneven ground. It can be extended, modified, or repaired without extensive structural changes.

- Visibility: The open mesh design allows for excellent visibility, aiding security personnel in monitoring perimeter activities without visual obstructions.

- Energy Saving (Indirect): By providing a reliable, long-lasting perimeter, it reduces the need for frequent patrols and maintenance, indirectly contributing to operational efficiency and resource conservation.

Figure 3: Chain link fence securing a large industrial facility.

Vendor Comparison and Strategic Procurement of Chain Link Fence

When sourcing wholesale chain link fence solutions, B2B buyers must evaluate vendors beyond just price. A strategic approach considers quality, certifications, lead times, and post-sales support.

Key Factors for Vendor Evaluation:

| Evaluation Criterion | Importance for B2B Procurement | Questions to Ask Vendors |

|---|---|---|

| Product Quality & Certifications | Ensures compliance with industry standards (e.g., ASTM A392 for galvanized chain link fence) and long-term performance. | "Are your products ASTM certified? Can you provide test reports for wire gauge, zinc coating, or PVC thickness?" |

| Manufacturing Capabilities | Indicates capacity for large orders (wholesale chain link fence) and ability to produce specialized configurations. | "What is your maximum daily production capacity? Do you handle custom mesh sizes or wire gauges?" |

| Customization Options | Crucial for projects with unique security, environmental, or aesthetic requirements. | "Can you provide PVC coated chain link fence in specific RAL colors? Do you offer special selvage options?" |

| Logistics & Lead Time | Timely delivery is critical for project schedules and cost control. | "What are your typical lead times for standard vs. custom orders? What shipping options are available for chain link fence wire roll?" |

| Technical Support & Warranty | Ensures assistance with installation, maintenance, and recourse for product defects. | "What is your product warranty? Do you offer technical support for installation challenges?" |

Customized Solutions for Specialized Chain Link Fence Applications

While standard chain link fence offers broad utility, many industrial projects necessitate tailored solutions to meet specific operational, environmental, or security challenges. Leading manufacturers provide extensive customization options.

Tailoring Fabric and Coatings

- Wire Gauge & Mesh Size: Custom combinations are available. For instance, a very small mesh (e.g., 1.25" or 32mm) with heavy gauge wire (e.g., 6 Ga) can be specified for maximum anti-climb and anti-cut properties, transforming a standard diamond mesh fence into a high-security barrier.

- Coating Systems: Beyond standard galvanization, specialized anti-corrosion treatments can be applied for marine environments or areas with high chemical exposure, significantly enhancing the resilience of the galvanized chain link fence. Dual coating systems (e.g., hot-dip galvanized and then PVC coated) offer the ultimate protection.

- Color Options: While green and black are common for PVC coated chain link fence, custom RAL colors can be specified to match corporate branding or blend seamlessly with architectural aesthetics, crucial for certain commercial B2B projects.

Integrated Security Enhancements

Customization extends to incorporating security features directly into the fence system:

- Barbed Wire/Razor Wire Topping: Multi-strand barbed wire or concertina razor wire can be pre-installed on extension arms, significantly increasing deterrence.

- Privacy Slats: These can be woven into the chain link fence mesh during manufacturing or installed post-fabrication, offering visual screening without compromising airflow.

- Gates and Access Points: Custom-fabricated swing gates, sliding gates, or cantilever gates, often automated and integrated with access control systems, are essential for complete perimeter solutions.

Figure 4: Specialized PVC coated chain link fence for environmental resistance.

Application Case Studies: Real-World Deployment of Chain Link Fence

The effectiveness of a chain link fence is best demonstrated through its successful deployment in critical industrial applications. These examples highlight the adaptability and reliability of the product.

Case Study 1: Perimeter Security for a Major Solar Farm

Client: Leading Renewable Energy Developer, Western USA.

Challenge: Secure a 500-acre remote solar farm against theft of valuable panels and equipment, as well as unauthorized access. The site experiences extreme temperature fluctuations and high UV exposure.

Solution: Installation of 8 miles of 8-foot high, 9-gauge galvanized chain link fence with a Class 3 zinc coating, topped with three strands of barbed wire. The galvanized chain link fence wire mesh provided excellent resistance to corrosion from dust and occasional rain, while the heavy gauge deterred cutting. The open mesh allowed for unobstructed views for remote CCTV monitoring. The project successfully achieved a zero-incident rate for intrusion over the first three years, demonstrating the efficacy of a robust chain link fence system in challenging environments.

Case Study 2: Chemical Plant Boundary in a Coastal Region

Client: International Chemical Manufacturing Corporation, Gulf Coast, USA.

Challenge: Establish a durable and corrosion-resistant perimeter around a chemical processing plant located near the coast, exposed to saltwater spray and various chemical fumes. The fence also needed to present a clean, professional aesthetic.

Solution: Deployment of a 10-foot high, 6-gauge PVC coated chain link fence (black color) over a Class 3 hot-dip galvanized core. The dual-layer protection offered by the PVC coated chain link fence provided superior resistance to both marine atmospheric corrosion and industrial chemical exposure. This cyclone fence solution not only met stringent safety and security requirements but also maintained its aesthetic appeal over an extended period, minimizing maintenance costs and enhancing the site's professional image.

Figure 5: High-security chain link fence with integrated access control.

Ensuring Trust: FAQs, Lead Times, Warranty, and Support

For B2B clients, trust is paramount. Our commitment to transparency in product quality, delivery, and post-sales support underpins every chain link fence solution we provide.

Frequently Asked Questions (FAQ)

- Q: What is the difference between galvanized and PVC coated chain link fence?

A: Galvanized chain link fence is steel wire coated with zinc for corrosion resistance. PVC coated chain link fence has an additional layer of PVC over the galvanized wire, offering superior aesthetics, enhanced corrosion resistance, and protection against UV and chemicals. - Q: How do I choose the right wire gauge and mesh size for my project?

A: Wire gauge determines strength (lower gauge = thicker wire). Mesh size affects security (smaller mesh = harder to climb). For high-security industrial applications, we generally recommend 9 gauge or 6 gauge wire with a 2-inch or 1.75-inch mesh size. Our technical team can provide detailed consultation. - Q: Can your chain link fence integrate with existing security systems?

A: Yes, our chain link fence systems are designed for seamless integration with a wide range of security technologies, including PIDS, CCTV, and access control. We can provide specifications compatible with your existing infrastructure. - Q: What is the lead time for large wholesale chain link fence orders?

A: Standard chain link fence wire roll orders typically have a lead time of 2-4 weeks. For large-volume wholesale chain link fence or highly customized orders, lead times can range from 4-8 weeks, depending on material availability and production queue. We prioritize clear communication on fulfillment details.

Lead Time and Fulfillment Details

We maintain a robust supply chain and efficient manufacturing processes to ensure timely delivery. Standard chain link fence products are typically dispatched within 10-14 business days. Custom orders or large wholesale chain link fence quantities may require additional time for fabrication and specialized coating, with estimated delivery dates provided upon order confirmation. We work with trusted logistics partners to ensure secure and efficient transportation of your chain link fence wire roll products to your specified location.

Warranty Commitments

Our chain link fence products are manufactured to stringent international standards. We offer a comprehensive warranty ranging from 10 to 20 years on galvanized products, and up to 15-25 years on PVC coated chain link fence, specifically covering manufacturing defects and premature corrosion under normal use conditions. Full warranty terms and conditions are available upon request, underscoring our confidence in product durability and quality.

Dedicated Customer Support

Our commitment extends beyond delivery. We provide dedicated technical support and after-sales service to assist with installation queries, maintenance best practices, and any operational challenges. Our team of experts is available via phone and email to ensure your chain link fence system performs optimally throughout its extensive service life.

References

- ASTM International. (2023). ASTM A392/A392M-23, Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric.

- ASTM International. (2023). ASTM F668/F668M-23, Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric.

- ISO. (2015). ISO 9001:2015, Quality management systems – Requirements.

- Zinc Institute. (2022). Galvanizing for Corrosion Protection: A Comprehensive Guide.

- Fence Industry Association. (2021). Best Practices for Industrial Fence Installation and Maintenance.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NoticiasNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NoticiasNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NoticiasNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NoticiasNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NoticiasNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NoticiasNov.11,2025