-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dic . 22, 2024 17:33 Back to list

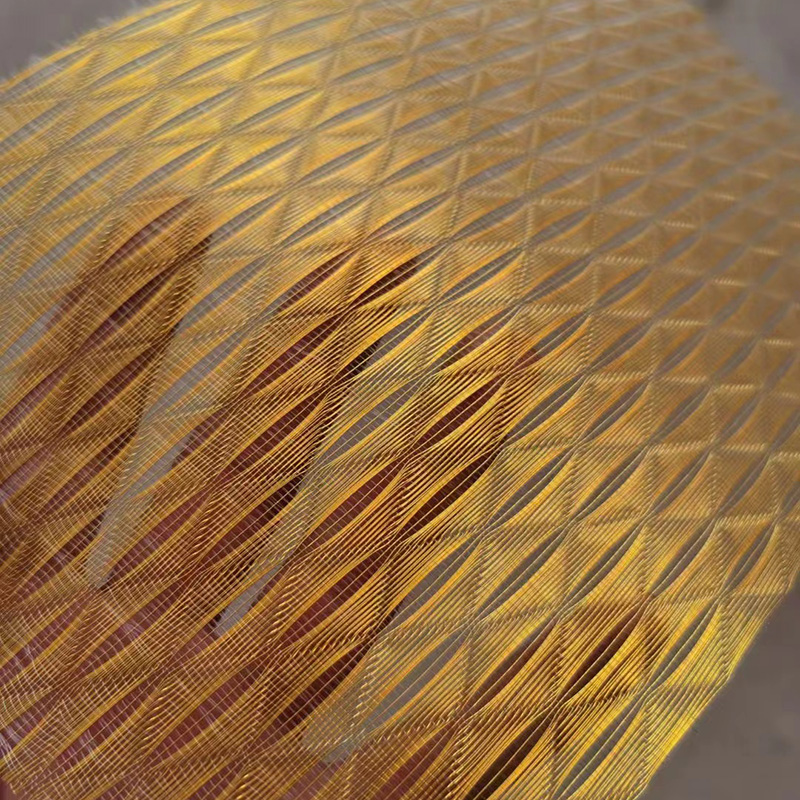

twisted soft annealed iron wire factory

The Art and Craft of Twisted Soft Annealed Iron Wire Innovation in Manufacturing

In the heart of many industrial processes, one might overlook the significance of seemingly simple materials like wire. However, twisted soft annealed iron wire emerges as a crucial element across various applications, from construction to crafting. This article delves into the fascinating world of its manufacturing, focusing on factories dedicated to producing this exceptional wire.

Understanding Twisted Soft Annealed Iron Wire

Twisted soft annealed iron wire is an alloy that has undergone a specific annealing process which makes it more malleable and ductile. The “twisted” aspect refers to the process of intertwining strands of wire, enhancing its tensile strength and flexibility. This type of wire finds uses in diverse fields such as fencing, mesh production, and even artistic endeavors. Its soft nature allows it to be easily shaped and manipulated, making it ideal for both industrial and artisanal applications.

The Manufacturing Process

The production of twisted soft annealed iron wire involves several meticulous steps. It begins with sourcing high-quality iron. In modern factories, the process utilizes advanced techniques to ensure the wire’s uniform composition and superior quality.

Once the iron is ready, it undergoes a series of heating processes. Annealing is crucial; it softens the metal, allowing it to be easily drawn into thinner wires. This process transforms the iron’s crystalline structure, giving it a softer, more ductile property. Temperature control plays a vital role here, as overheating can damage the metal’s integrity.

After annealing, the wire is drawn through successively smaller dies. This cold drawing increases its length while decreasing its diameter, offering precise control over the wire’s thickness. The next step is twisting; multiple strands of wire are twisted together to enhance strength and flexibility, making it suitable for various applications.

Quality Control Measures

twisted soft annealed iron wire factory

Quality control is imperative in a twisted soft annealed iron wire factory. Each batch undergoes rigorous testing for tensile strength, flexibility, and resistance to rust. Factories implement advanced technology, including automated machinery equipped with sensors that monitor the physical properties of the wire in real time. This meticulous scrutiny ensures that only the highest quality products reach the market.

Applications Across Industries

The versatility of twisted soft annealed iron wire allows it to be utilized across multiple industries. In construction, it is used for reinforcing concrete and creating secure fencing structures. Gardeners and landscapers often rely on it for trellises and supports, as its malleability makes it simple to work with.

Moreover, it serves a functional role in manufacturing processes, such as producing mesh or netting for safety barriers and other protective applications. Beyond utility, artists and craftsmen use twisted soft annealed iron wire for sculptures, jewelry, and decorative pieces. Its aesthetic appeal, combined with its functional properties, has inspired a myriad of creative uses.

Sustainable Practices in Manufacturing

Modern factories are increasingly adopting sustainable practices in the production of twisted soft annealed iron wire. This includes recycling scrap metal, reducing energy consumption during the manufacturing process, and minimizing waste. Governments and industries are advocating for eco-friendly practices, and many factories have shifted towards greener alternatives to ensure a minimal environmental footprint.

Conclusion

Twisted soft annealed iron wire may appear unassuming, yet it plays an instrumental role in various sectors, demonstrating both strength and versatility. The manufacturing process, grounded in precision and quality, showcases the craftsmanship involved in creating a material that seamlessly marries function with form. As industries evolve and seek sustainable solutions, the significance of twisted soft annealed iron wire will only continue to grow, underscoring the intricate relationship between traditional manufacturing and modern innovation.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025