-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Ene . 06, 2025 19:10 Back to list

galvanized welded wire mesh

Navigating the expansive world of construction materials, welded wire mesh emerges as an indispensable asset. This versatile, durable, and economical material plays a pivotal role in modern infrastructure, offering an unmatched combination of strength and flexibility. As a testament to its growing popularity, welded wire mesh is increasingly used across various applications, from residential projects to comprehensive infrastructure developments.

In essence, welded wire mesh is a prefabricated grid constructed from stainless steel or carbon steel wires that are electrically welded at intersections. The result is a robust panel with uniform spacing that ensures consistent reinforcement. The production technique itself is a marvel of engineering precision, designed to meet the stringent demands of today’s construction industry for stability and safety.

In the complex arena of civil engineering, the practicality of welded wire mesh cannot be understated. Its application ranges from reinforcing concrete slabs to providing structural support for walls and columns. Unlike traditional materials, welded wire mesh offers superior tensile strength due to its welded junctions, enabling it to withstand substantial loads and resist deformation. This proves invaluable in high-pressure environments such as sewer systems, tunnels, and retaining walls, where structural integrity is paramount.

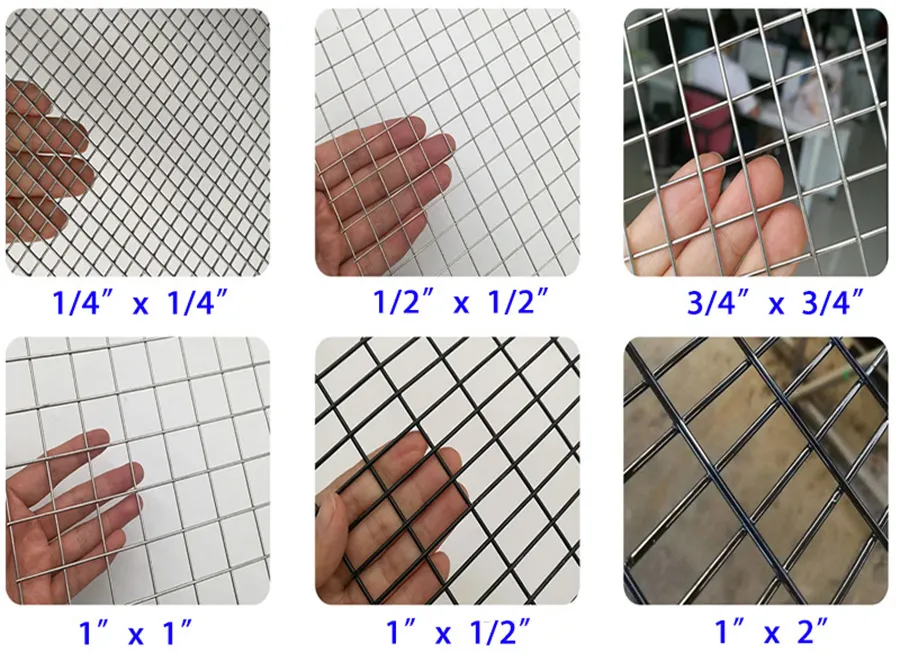

As a recognized expert in construction materials, the efficacy of welded wire mesh is not only observed but also scientifically substantiated. Studies highlight its considerable advantages over traditional steel reinforcement bars. Specifically, its prefabricated nature reduces on-site installation time significantly, leading to cost efficiencies. With the ability to tailor mesh sizes to specific project needs, builders achieve optimal material usage, minimizing waste and therefore contributing positively to sustainable building practices.

welded wire mesh

Professionals across the industry acknowledge welded wire mesh’s versatility. It adapts seamlessly into prefabricated concrete components and modular construction approaches that are proliferating in contemporary architecture. For example, in precast construction methods, the use of welded wire mesh enhances the quality and durability of components such as wall panels, beams, and roofing elements, thereby extending their lifespan and reducing maintenance costs.

Beyond technical supremacy, the reliability of welded wire mesh is anchored in compliance with international standards such as ASTM A185/A185M. Adherence to such standards ensures high quality and uniformity, essential factors for construction materials to gain industry-wide trust. These standards set the benchmark for quality control processes, ensuring that each piece of welded wire mesh meets the safety and performance criteria vital for critical construction ventures.

The strategic investment in welded wire mesh consequently signifies a commitment to quality and longevity, attractive to stakeholders seeking sustainable and economical solutions. Companies and construction professionals vouch for its performance through real-world successes, reinforcing the material's authoritative status in the industry. Such endorsements build a foundation of trust, exemplified by decades of proven field performance that mitigates risk and enhances accountability in project delivery.

To encapsulate, welded wire mesh isn’t merely a product; it is an innovation that epitomizes the confluence of expertise, reliability, and efficiency. As the architectural landscape continues to evolve, its role is set to expand, solidifying its position as a preferred choice among the construction professionals who shape tomorrow’s infrastructure today.

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025