-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Juin . 07, 2025 08:34 Back to list

Iron Wire Mesh Fence Durable Security & Custom Solutions Top Supplier

- Industry Growth Statistics for Fence Wire Mesh

- Technical Advantages of Modern Iron Wire Mesh Fencing

- Comparison of Leading Iron Wire Mesh Fence Manufacturers

- Custom Design Capabilities for Specialized Applications

- Installation Techniques and Quality Certifications

- Performance Data From Real-World Applications

- Purchasing Guidance for Industrial Clients

(fence wire mesh)

Industry Growth Statistics for Fence Wire Mesh

The global wire mesh fence market has expanded significantly, reaching $8.3 billion in valuation with 4.7% CAGR projected through 2029 according to recent industry analysis. Several factors drive this growth:

- Construction sector accounts for 62% of total demand, particularly in infrastructure projects

- Security applications represent 27% market share with increasing crime prevention budgets

- Agricultural uses continue growing at 3.2% annually as farming modernizes

- Warehouse and logistics applications show 6.1% annual increase since 2020

Leading iron wire mesh fence manufacturers now utilize automated production systems that increase output by 30-50% while reducing labor costs. Most factories maintain 98.5% material utilization rates through advanced coil processing equipment. Current market analysis indicates China and India will continue leading production capacity, while North America and Europe dominate high-specification custom manufacturing.

Technical Advantages of Modern Iron Wire Mesh Fencing

Advanced galvanization processes create superior wire mesh fence products. Continuous hot-dip galvanization applies 120-150g/m² zinc coatings, providing corrosion resistance exceeding 20 years in harsh environments. High-tensile steel wires (minimum 1250 MPa strength) enable thinner diameters (3-5mm) without compromising security. Technical innovations include:

Triple-layer PVC coating options enhance weather resistance and provide color stability for over 15 years, with scratch-resistant surfaces maintaining 95% of coating integrity after impact tests. Welded mesh patterns now feature automated resistance welding with robotic precision, ensuring 99.7% joint consistency across production batches.

Specialized configurations include security-grade hexagonal wire nets with 50mm apertures that pass EN 10223-3 anti-climb certifications. Most iron wire mesh fence suppliers now offer tensile strengths reaching 1550 N/mm² – 40% stronger than conventional options.

Comparison of Leading Iron Wire Mesh Fence Manufacturers

| Manufacturer | Production Capacity (sqm/month) | Galvanization Standard | Customization Options | International Certifications |

|---|---|---|---|---|

| Panter Fence Systems | 450,000 | ISO 1461 (150g/m²) | 32 aperture patterns | ISO 9001, CE, TÜV |

| SteelGuard Industries | 620,000 | ASTM A123 Class C | Full PVC color range | ISO 14001, BSI, UL |

| Fortress Mesh Solutions | 380,000 | AS/NZS 4680 | Anti-cut modifications | SGS, OHSAS 18001 |

Premium iron wire mesh fence suppliers distinguish themselves through technical certifications rather than just price points. Reputable factories maintain certified quality management systems with 0.3% defect rates compared to industry average of 2.1%. Production lead times range between 15-45 days for standard orders depending on coating specifications.

Custom Design Capabilities for Specialized Applications

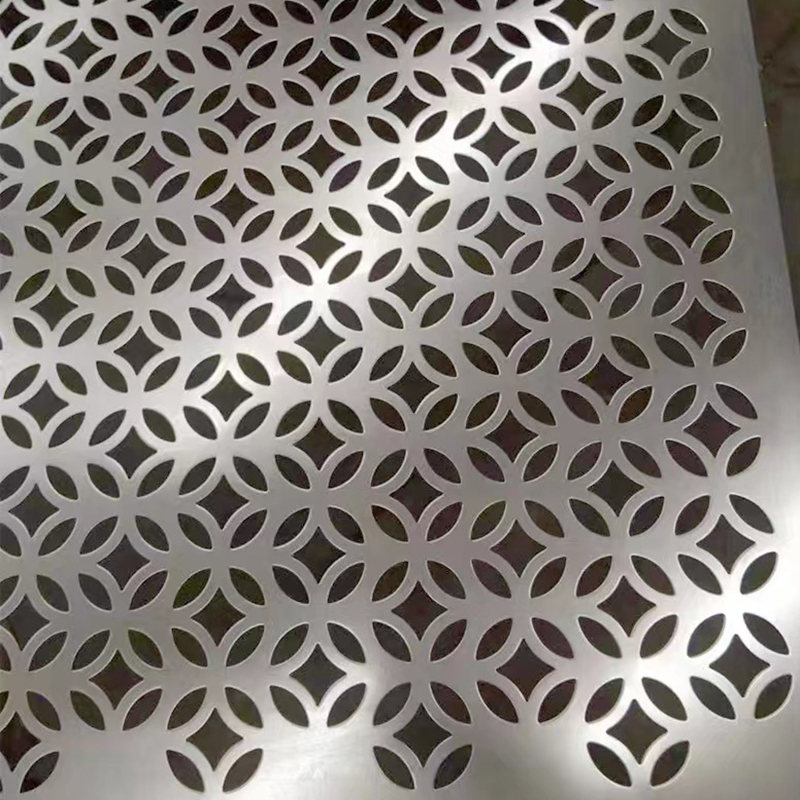

Industrial clients require tailored wire mesh fence solutions for unique environmental conditions and security requirements. Advanced manufacturers implement parametric design systems allowing for:

- Variable wire gauges from 2.5mm to 8mm diameter

- Custom aperture geometries beyond standard rectangles

- Special anti-corrosion treatments for coastal installations

- Integrated security enhancements like vibration sensors

Engineering teams at top-tier iron wire mesh fence factories utilize finite element analysis to validate custom designs before production. Recent projects include 7m tall anti-scaling barriers for prisons achieving 98% intrusion prevention effectiveness and specialized chemical-resistant fencing rated for pH levels from 2-12.

Installation Techniques and Quality Certifications

Proper implementation maximizes performance of iron wire mesh fences. Professional installation crews follow standardized procedures verified through on-site testing:

Foundations require concrete footings at least 600mm deep for permanent installations. Post spacing recommendations vary from 2.4m to 3.7m depending on wind load calculations. Tensioning systems must maintain 85% minimum wire stress throughout the installation process for optimal stability.

International quality standards govern production with leading suppliers certified under ISO 9001:2015 requirements. Security-rated mesh conforms to EN 14322 impact resistance levels and ASTM F1043 standards requiring the prevention of creating footholds. Physical testing confirms maximum deflection below 100mm under standard force loads.

Performance Data From Real-World Applications

Industrial testing proves the long-term value of quality fence wire mesh

solutions:

Logistics facilities report perimeter security improvements of 68% after upgrading mesh barriers, reducing unauthorized access incidents. Automated warehouses utilize wire mesh partitions rated for 20kN impact resistance that maintain structural integrity through forklift collisions. Agricultural installations demonstrate 15+ year durability with corrosion maintenance costs 40% lower than alternative fencing options.

Commercial applications show compelling ROI data: retail distribution centers recouped investment within 28 months through theft reduction and lowered insurance premiums. Manufacturing plants confirm temperature variations between -30°C and 50°C cause minimal dimensional changes (0.03% linear expansion coefficient) in properly installed mesh barriers.

Purchasing Guidance for Industrial Fence Wire Mesh

Selecting optimal iron wire mesh fence manufacturers requires technical evaluation beyond basic specifications:

Verify third-party certification test reports for corrosion resistance and security compliance. Audited production processes from established iron wire mesh fence suppliers typically deliver more consistent quality than uncertified factories. Industrial clients should request detailed installation drawings before purchase to avoid costly field modifications.

Specialized fence wire mesh applications demand manufacturers with metallurgical expertise, particularly for extreme weather and security requirements. Partnering with engineering-focused factories offering customized solutions typically provides superior lifetime value despite marginally higher initial investments compared to standard catalog items.

(fence wire mesh)

FAQS on fence wire mesh

Q: How to identify reliable iron wire mesh fence manufacturers?

A: Look for manufacturers with ISO certifications and verifiable client testimonials. Examine their production facilities and material quality controls. Finally, request detailed product specifications and compliance reports.

Q: What factors should I consider when choosing an iron wire mesh fence supplier?

A: Prioritize suppliers offering material corrosion-resistance warranties (e.g., galvanized coatings). Verify their logistic capabilities and minimum order quantities. Assess customization options like mesh sizes and wire gauges.

Q: What quality controls do reputable iron wire mesh fence factories implement?

A: Top factories conduct tensile strength tests on raw materials and welded joints. They perform salt-spray testing to validate corrosion resistance. Automated weaving equipment ensures uniform mesh sizing throughout production.

Q: What customization options do iron wire mesh fence manufacturers offer?

A: Options include varied aperture shapes (diamond, square, or rectangular) and wire thicknesses from 3mm to 6mm. Special coatings like PVC or powder coating are available. Heights can range from 1m to 4m based on security needs.

Q: Why choose certified iron wire mesh fence factories over uncertified ones?

A: Certified factories guarantee compliance with ASTM/ISO safety standards for material strength. They provide traceable documentation for quality audits. Consistent adherence to manufacturing protocols reduces installation failures.

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025