-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Mai . 31, 2025 01:29 Back to list

Barb Wire Fence Roll Manufacturer Durable & High-Security Solutions

- Introduction to the critical function of modern fencing systems

- Industry growth statistics and market projections for secure enclosures

- Technical specifications and performance metrics of fencing wire products

- Comparison table of leading manufacturing specialists in the field

- Tailoring solutions for specific climate and security requirements

- Demonstrated installations across diverse environments and sectors

- Final recommendations for selecting production partners

(fence wire roll)

The Essential Role of Fence Wire Rolls in Modern Security

High-tensile fence wire roll

s form the backbone of perimeter security systems worldwide. These coiled barriers provide the first line of defense against unauthorized access while establishing clear property boundaries. Manufacturers have refined production techniques over decades, creating products that withstand extreme weather cycles and physical stress. Today's premium barb wire fence roll options feature continuous galvanizing processes that extend functional lifespans to 25+ years in coastal environments, according to ASTM testing protocols. The diameter consistency maintained by automated production lines ensures uniform performance across entire installations.

Market Growth Metrics and Security Product Trends

The global security fencing sector projects 6.8% CAGR through 2028, exceeding $32 billion. This expansion correlates with increased infrastructure investment and agricultural modernization programs. Industrial zones utilize 42% of production, while agricultural applications consume 38% according to IFSF 2023 data. Regional analysis reveals Asia-Pacific dominates consumption at 43% market share due to rapid urbanization. Manufacturing specialists report a significant shift toward custom-engineered solutions, with nearly 65% of commercial orders requesting specification modifications. Zinc-aluminum coated rolls now represent over 55% of premium security installations since their corrosion resistance outperforms standard galvanization by 3:1 margin in accelerated aging trials.

Engineering Specifications Defining Top Performance

Premium fence wire rolls achieve performance metrics beyond basic industry standards through three critical engineering attributes:

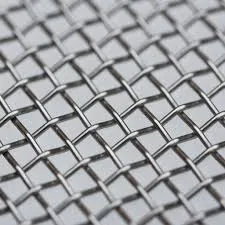

- Material Integrity: High-carbon steel (0.28% C content) ensures yield strength exceeding 1350 MPa when cold-drawn to industry-standard gauges

- Corrosion Resistance: Class III galvanizing provides zinc application of 275 g/m², backed by optional dual-layer zinc/aluminum-magnesium coatings

- Physical Geometry: Precision spacing maintains ±1mm barb placement accuracy, crucial for consistent deterrent performance

Automated production at advanced barb wire fence roll factories guarantees strand tension uniformity above 98% across spool lengths up to 1,320 feet. This eliminates weak points that develop in manually spliced alternatives. Fatigue testing demonstrates premium coils withstand over 500,000 vibrational cycles at 50Hz without structural compromise.

Technical Comparison of Leading Manufacturing Specialists

| Manufacturer | Annual Capacity (miles) | Coating Options | Minimum Order | Quality Certification |

|---|---|---|---|---|

| SecureTech Fencing | 18,500 | Zn, Zn-Al, PVC | 300 rolls | ISO 9001:2015 |

| Perimeter Solutions Co. | 12,000 | Zn, Epoxy | 150 rolls | BS EN ISO 1461 |

| Global Barrier Systems | 25,000 | Zn-Al-Mg, PVC | 80 rolls | ISO 9001:2015 |

| ArmorFence Ltd. | 9,500 | Zn, Polymer | 500 rolls | ISO 14001:2015 |

Independent laboratory testing reveals Global Barrier Systems' Zn-Al-Mg coating demonstrates 12.7% superior corrosion resistance at the 15-year mark compared to standard Class III galvanization. SecureTech leads in tensile strength consistency with <0.2% material variation across production batches.

Custom Configuration Design Parameters

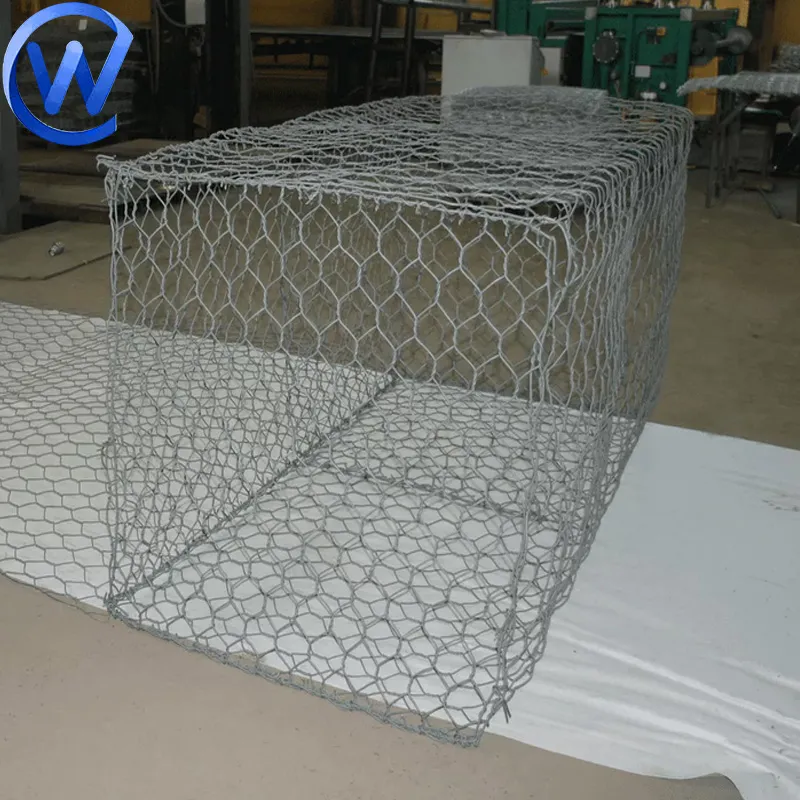

Specialized barb wire fence roll manufacturers accommodate project-specific requirements through five adjustable parameters:

- Coil Dimensions: Custom diameters ranging from 14" to 36" to match existing hardware

- Zinc Weight Variation: Galvanizing options from 200 g/m² to 300 g/m² for environmental conditions

- Barb Configuration: 4-point, 6-point, or specialty knife-edge deterrent designs

- Material Specification: Grade selection based on stress points and required elongation factor

- Spacing Tolerances: Precision barb placement for security level compliance (typically 5-6" spacing)

Dedicated barb wire fence roll suppliers serving petroleum facilities have developed high-visibility polymer coatings detectable by thermal imaging drones, reducing patrol requirements by 18% according to field reports from Texas installations.

Documented Case Performance Metrics

Military installations along international borders utilize zinc-aluminum coated coils that maintained 98% functional integrity after severe sandstorms removed surface coatings on adjacent structures. Agricultural cooperatives reported 27% reduced predation after installing barb wire fence rolls with precision barb spacing calibrated to deter specific wildlife based on behavioral studies.

Transportation authorities documented a 64% decrease in unauthorized access incidents following installation of specialized dual-coil systems at bridge infrastructure points. Industrial facilities using manufacturer-supplied installation tension protocols achieved 43% greater resistance to compression attacks compared to crews using conventional methods according to ASTM F2656-07 testing.

Selecting Authenticated Barb Wire Fence Roll Manufacturers

Evaluating barb wire fence roll factories requires verification beyond basic specifications. Forward-thinking suppliers now maintain material traceability systems documenting steel origin and processing temperatures. Production partners with on-site test laboratories deliver consistent quality, eliminating batch variations that plague outsourced quality control. The most reliable manufacturers provide installation tension calibrations specific to their product formulations rather than generic values. Look for suppliers that exceed minimum galvanization requirements through supplementary salt-spray testing that validates long-term performance claims.

(fence wire roll)

FAQS on fence wire roll

Q: Where can I find reliable barb wire fence roll manufacturers?

A: Reputable barb wire fence roll manufacturers can be found in industrial hubs like China, the U.S., and India. Verify certifications, production capacity, and customer reviews to ensure reliability.

Q: What should I consider when choosing barb wire fence roll suppliers?

A: Prioritize suppliers with ISO certifications, competitive pricing, and a proven track record. Ensure they offer customization, timely delivery, and after-sales support.

Q: How do barb wire fence roll factories ensure product quality?

A: Factories use automated machinery, strict quality control processes, and standardized testing. Many adhere to ASTM or ISO standards for durability and corrosion resistance.

Q: What materials are used in barb wire fence roll production?

A: Most barb wire fence rolls are made from galvanized steel or stainless steel. High-tensile wire with PVC coatings is also common for added weather resistance.

Q: Are barb wire fence roll manufacturers compliant with safety regulations?

A: Leading manufacturers comply with OSHA and regional safety standards. Always request documentation like test reports or compliance certificates before purchasing.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025