-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 05, 2024 07:39 Back to list

galvanized wire mesh factory

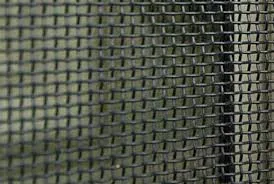

Understanding Galvanized Wire Mesh and Its Manufacturing Process

Galvanized wire mesh has become an essential component in various industries, thanks to its durability, corrosion resistance, and versatile applications. It is made by weaving together strands of wire that have undergone a galvanization process, which involves applying a protective zinc coating. This coating not only enhances the wire's lifespan but also improves its resistance to environmental factors, making it ideal for outdoor use.

The manufacturing process of galvanized wire mesh starts with the selection of high-quality steel wire. The wire is drawn to the desired thickness, which can vary depending on the intended application. Common gauges for wire mesh range from 8 to 24, with thicker wires providing added strength and durability. Once the wire is prepared, it is subjected to the galvanization process. There are two primary methods of galvanization hot-dip galvanization and electro-galvanization.

In hot-dip galvanization, the wire is immersed in molten zinc, creating a thick and robust coating. This method is favored for its longevity and superior protection against rust and wear. On the other hand, electro-galvanization involves electroplating the wire with zinc, yielding a thinner coating. While this method provides some protection, it may not be as durable as hot-dip galvanization, making it more suitable for indoor applications.

galvanized wire mesh factory

After the galvanization process, the wire is cut into appropriate lengths and assembled into mesh sheets. The mesh can vary in terms of hole size and pattern, depending on specific project requirements. Common configurations include square and rectangular openings, which can be customized to suit unique applications.

The applications of galvanized wire mesh are vast. In agriculture, it is used for fencing, animal enclosures, and crop protection. In construction, it serves as reinforcement in concrete and provides structural support for building frameworks. Additionally, galvanized wire mesh finds use in landscaping, creating barriers, and as decorative elements in architecture.

Choosing a reliable galvanized wire mesh factory is crucial for obtaining high-quality products. Such a factory should adhere to stringent quality control measures and industry standards. A reputable manufacturer will also offer customization options and a variety of mesh sizes to meet diverse needs.

In summary, galvanized wire mesh is a versatile and essential material that offers strength, durability, and resistance to corrosion. Understanding its manufacturing process and applications is vital for industries looking to leverage its benefits effectively.

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025