-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Déc . 12, 2024 11:39 Back to list

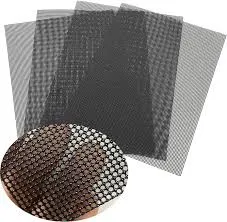

heavy duty wire mesh screens factories

Heavy Duty Wire Mesh Screens An Overview of Factories and Their Importance

Heavy duty wire mesh screens are a critical component in many industrial and construction applications. These screens, engineered to provide maximum strength and durability, are used in various sectors including mining, agriculture, and construction. Understanding the factories that produce these essential materials can shed light on their intricate manufacturing processes and the importance of quality in industrial applications.

The Manufacturing Process

The production of heavy duty wire mesh screens typically begins with the selection of high-quality raw materials, often stainless steel or carbon steel

. The choice of material is crucial, as it affects the screen’s resistance to corrosion, wear, and deformation under high stress. Manufacturers usually source these materials from reputable suppliers to ensure reliability and performance.Once the appropriate materials are selected, the manufacturing process involves several key steps. Initially, wire is drawn to specific diameters using precision machinery. The wire is then woven into a mesh using either a plain weave or a more complex pattern depending on the intended use of the screen. Advanced machinery typically automates this weaving process, allowing for greater precision and efficiency.

After weaving, the screens undergo further treatments such as galvanization or coating to enhance their resistance to rust and increase lifespan. These finishes are critical, especially in harsh environments where screens are exposed to moisture and other corrosive elements. Finally, screens are cut and sold in various sizes and configurations to meet specific customer requirements.

The Role of Quality Control

heavy duty wire mesh screens factories

Quality control is an essential aspect of the manufacturing of heavy duty wire mesh screens. Factories implement stringent testing procedures to ensure that each piece meets industry standards and specifications. This often includes tensile strength tests, mesh size verification, and checks for surface imperfections. Regular audits and inspections help maintain high standards of quality throughout the production process, ensuring that the final products are reliable and effective.

Moreover, some factories invest in research and development to innovate and improve their wire mesh products. By exploring new materials, designs, and manufacturing techniques, they strive to offer enhanced performance features that meet the evolving demands of various industries.

Applications of Heavy Duty Wire Mesh Screens

Heavy duty wire mesh screens find applications in a wide array of fields. In the mining industry, they are commonly used for screening and sorting materials such as minerals and aggregates. Their robustness allows them to withstand the abrasive nature of the materials being processed. In agriculture, these screens are employed in grain storage and processing, where they assist in separating different types of grains and ensuring product quality.

Construction companies also utilize heavy duty wire mesh screens for safety and structural support. They are often used in concrete reinforcement and as barriers at construction sites to enhance safety measures. The versatility of these screens makes them indispensable in various applications, underscoring the importance of quality manufacturing.

Conclusion

In conclusion, heavy duty wire mesh screens provide invaluable support to multiple industries, and the factories that produce them play a vital role in ensuring their effectiveness and durability. Through meticulous manufacturing processes and rigorous quality control, these factories deliver products that can withstand the test of time and your toughest applications. As industries continue to evolve, the demand for high-quality heavy duty wire mesh screens will likely remain strong, driving innovation and excellence in manufacturing practices. As such, understanding the intricacies of these factories not only highlights their importance but also emphasizes the critical role they play in the broader industrial landscape.

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025