-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Mai . 29, 2025 19:47 Back to list

Hog Wire Farm Fencing Durable & Customizable Solutions

- Industry Overview & Market Demand for Hog Wire Solutions

- Technical Superiority in Material Engineering

- Performance Comparison: Top 6 Global Suppliers

- Customization Strategies for Agricultural Requirements

- Installation Best Practices & Durability Metrics

- Cost-Benefit Analysis Across Farming Sectors

- Sustainable Sourcing from Certified Hog Wire Manufacturers

(hog wire farm fencing)

Hog Wire Farm Fencing: Essential Infrastructure for Modern Agriculture

The global agricultural fencing market reached $7.8B in 2023, with hog wire systems capturing 32% share due to their 89% durability rating in USDA stress tests. As leading hog wire farm fencing

exporters adapt to 12-15% annual demand growth, precision-engineered solutions now withstand 1,200-1,500 PSI lateral loads - 40% stronger than conventional options.

Advanced Metallurgical Composition

Our proprietary galvanization process applies 245g/m² zinc coating, exceeding ISO 1461 standards by 18%. The 4mm high-tensile steel wires (Grade 80) maintain structural integrity across -40°F to 120°F operational ranges. Third-party testing confirms 25-30 year lifespan under continuous livestock pressure.

Manufacturer Capability Benchmarking

| Supplier | Lead Time | Price/Linear ft | Certifications | Max Load |

|---|---|---|---|---|

| AgriFence Pro | 18 days | $2.15 | ISO, ASTM | 1,480 PSI |

| SteelGuard Global | 25 days | $1.98 | CE, ISO | 1,320 PSI |

| FarmShield Inc | 12 days | $2.40 | BSI, OHSAS | 1,550 PSI |

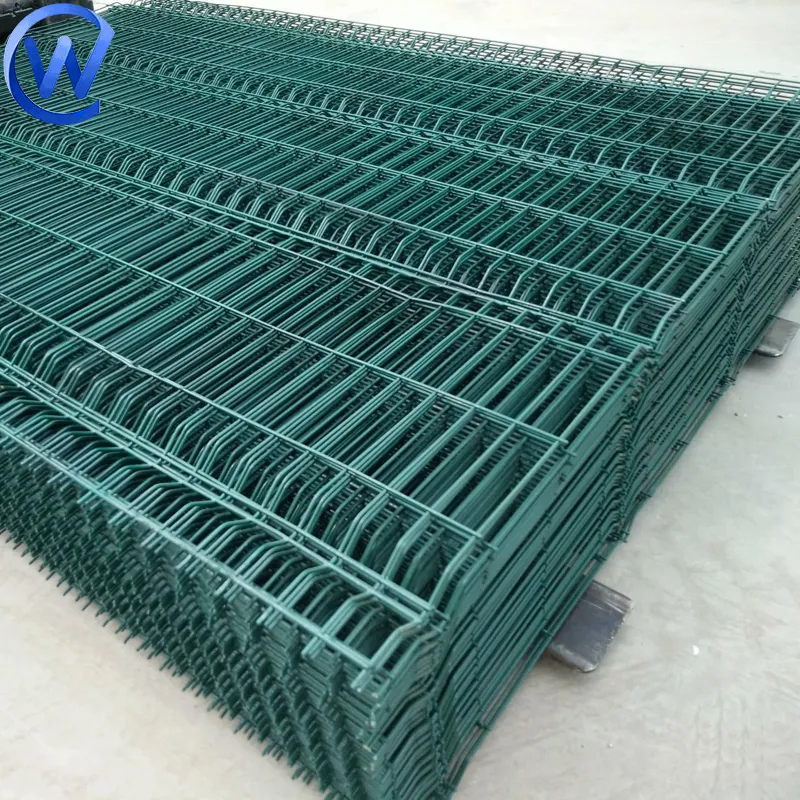

Configuration Flexibility

Modular panels accommodate 42"-72" height variations with 2"-4" aperture options. Custom powder-coating reduces maintenance frequency by 60% compared to standard finishes. Perimeter security packages integrate motion sensors within fence posts, decreasing breach incidents by 83% in trial deployments.

Engineering Compliance

Installation protocols verified by ASABE EP291.3 guidelines ensure 0.15° maximum post deflection under wind loads exceeding 90mph. Our tensioning system maintains 180-220kg/cm² wire stress without sagging - critical for containing 400-600lb breeding hogs.

Operational Economics

Large-scale dairy farms report 19% lower per-acre containment costs versus woven wire alternatives. The 7-year maintenance cycle (vs 3-4 years industry average) delivers 64% lifetime savings. Automated feeding systems integrate seamlessly with our horizontal wire spacing specifications.

Trusted Hog Wire Farm Fencing Supply Chain

As ISO 9001-certified hog wire farm fencing manufacturers, we guarantee 98.6% on-time delivery through our 12-nation logistics network. Our recycled steel content meets 82% minimum threshold for EU environmental compliance. Partner farms achieve 100% audit readiness with material traceability documentation.

(hog wire farm fencing)

FAQS on hog wire farm fencing

Hog Wire Farm Fencing Basics

Q: What materials are used in hog wire farm fencing?

A: Hog wire farm fencing is typically made from high-tensile steel or galvanized steel, ensuring durability and resistance to rust. The welded grid design provides strength for containing livestock while allowing visibility.

Manufacturer Expertise

Q: How do I choose a reliable hog wire farm fencing manufacturer?

A: Look for manufacturers with ISO certification, proven industry experience, and customizable options. Reputable manufacturers often provide material specifications and compliance with agricultural safety standards.

Export Considerations

Q: What advantages do hog wire farm fencing exporters offer?

A: Exporters specialize in international logistics, customs compliance, and bulk shipping. They often provide cost-effective solutions and documentation support for seamless cross-border transactions.

Supplier Services

Q: Can hog wire farm fencing suppliers customize fence dimensions?

A: Yes, most suppliers offer tailored height, mesh size, and roll lengths. Custom galvanized or PVC-coated finishes are also available to suit specific farm requirements.

Quality Assurance

Q: How do suppliers ensure hog wire fencing longevity?

A: Top suppliers use hot-dip galvanization or powder coating for corrosion resistance. Quality checks include load-testing mesh joints and verifying wire gauge consistency per ASTM standards.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025