-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Juil . 29, 2025 14:20 Back to list

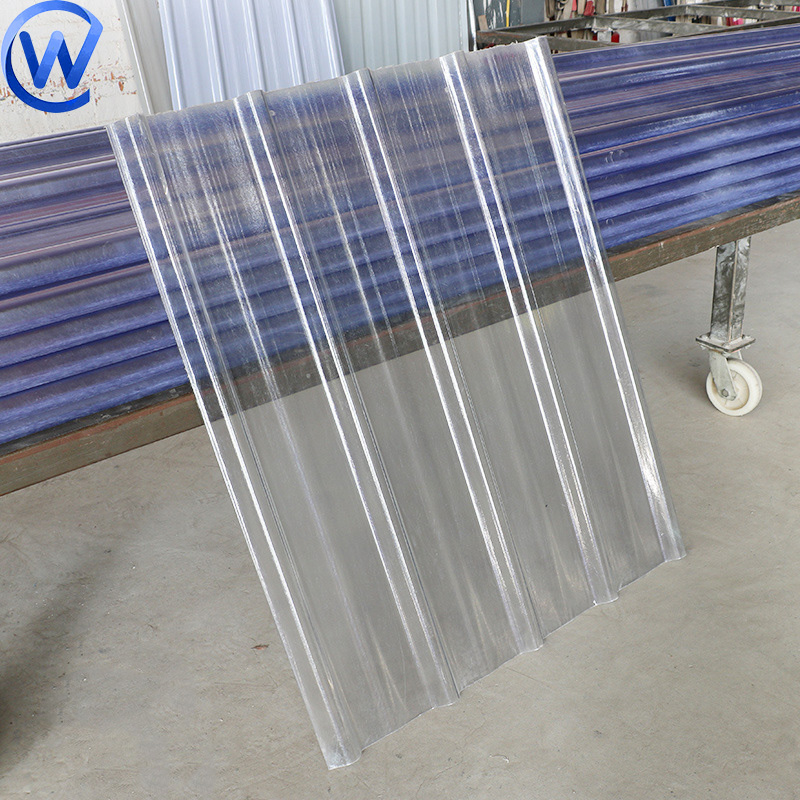

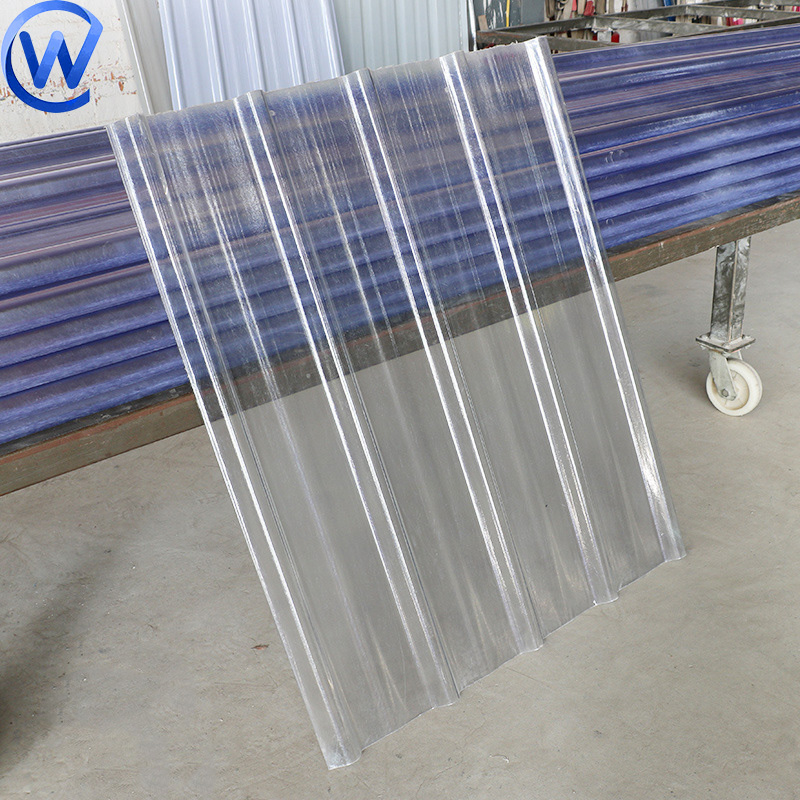

Premium Roof Tiles for Durable & Stylish Roofing Solutions

Roof Tiles are the foundation of modern roofing systems, providing durability, weather-resistance, and architectural value to industrial, commercial, and residential buildings worldwide. With evolving technologies, high-grade materials, and customized solutions, the Roof Tiles market is witnessing exponential growth and diversified applications across industries.

1. Industry Overview and Market Trends

The global Roof Tiles market exceeded USD 29 billion in 2023 and is expected to reach USD 37.8 billion by 2028 (source), marking a CAGR of over 5.4%. Major industry drivers include increasing urbanization, sustainable construction, advancement in manufacturing (like CNC and robotic molding), and stricter compliance with standards such as ISO 9001 and EN 490.

Today, Roof Tiles are engineered with a blend of traditional craftsmanship and automated precision, catering to sectors from petrochemical to civil engineering. Key industry trends are:

- Growing demand for eco-friendly & recycled roof tile materials (clay composites, advanced ceramics, galvanized metals)

- Integration of energy-saving coatings (IR-reflective, thermal insulators)

- Use of advanced surface treatments for anti-corrosion and longevity

- Wider adoption of modular, CNC-cut designs for fast installation

2. Technical Specifications & Comparative Analysis

Main Technical Parameters of Roof Tiles

| Parameter | Ceramic Roof Tile | Galvanized Steel Roof Tile | Clay Roof Tile | Concrete Roof Tile |

|---|---|---|---|---|

| Standard Dimensions (mm) | 420×330×13 | 1200×400×15 | 410×250×12 | 420×335×14 |

| Weight / m² | 43 kg | 18 kg | 38 kg | 47 kg |

| Water Absorption (%) | ≦6 | 0 | 6-9 | 5-9 |

| Bending Strength (MPa) | 15-24 | ≥30 | 12-18 | 12-22 |

| Thermal Conductivity (W/mK) | 0.85 | 45 | 0.90 | 1.1 |

| Service Life (years) | 40–60 | 30–50 | 50–80 | 30–40 |

| Fireproof Grade | A1 | A1 | A1 | A1 |

| Compliant Standards | EN 490, ISO 9001 | ASTM A653, ISO 14001 | EN 1304, ISO 9001 | EN 490, ANSI Z97.1 |

Product Comparison Chart

3. Manufacturing Process of Roof Tiles

- Raw Material Preparation

High-purity clay, silica, and high-tensile galvanized steel (as per ISO 10545/ASTM A653) are sourced for batch preparation. - → Precise Molding (CNC/Pressing/Extrusion)

Automated CNC shaping ensures high dimensional accuracy (±0.3mm). - → Firing/Heat Treatment

Kiln firing at 1050°C (ceramics) or galvanizing for metals for anti-corrosion. - → Surface Treatment & Glazing

Application of IR-reflective coating and weatherproof glazing. - → Precision Trimming

Robotic CNC trimming for perfect fit, burr removal, and finishing. - → Automated Inspection

Dimensional and surface defect scanning, according to ISO 9044/ANSI A137.1 protocols. Defect rate <0.2% per batch. - → Packaging & Logistics

Integration of RFID-traceable packaging for efficient tracking.

4. Key Material Characteristics & Testing Standards

- Ceramic and clay Roof Tiles: High compressive strength (≥23 MPa), water absorption below 7%, high-fire resistance; recommended by AS 2049.

- Galvanized steel Roof Tiles: Compliant with ASTM A653 and ISO 14001 for surface coating & corrosion resistance; salt-spray test result: corrosion starting >1,300 hrs.

- All types: Pass EN 490 wind uplift & freeze-thaw cycling requirements.

Durability: Leading products exhibit minimal color fading (<3%) and maintain ≥90% tensile strength after 10 years of exposure (per ISO 10545-13, EN 1304).

5. Data Visualization: Technology Trends & Market Analysis

6. Manufacturer Comparison: Roof Tiles Quality Benchmarking

| Manufacturer | Product Series | Primary Material | Certifications | Key Features | Typical Lead Time |

|---|---|---|---|---|---|

| Galvanized Mesh Products | GMT Ultra-Tough | Galvanized Steel Alloy | ISO 9001, RoHS, ASTM A653 | CNC-edge; corrosion-resistant; windproof clamps; custom sizes | 10–15 days |

| Monier | Duratop Ceramic | Ceramic | EN 490, ISO 10545 | UV glazed; up to 60-year lifespan; 100% recyclable; fast mounting | 12–21 days |

| Boral | EcoSlate | Clay | EN 1304, ISO 9001 | Natural color; low absorption; thermal barrier layer | 15–18 days |

| Ludowici | Classic Line | Concrete | EN 490, ANSI Z97.1 | High-strength; anti-slip surface; freeze-thaw stable | 12–17 days |

7. Customization Solutions & Service Capabilities

Available Customizations:

- Material grades (ceramic, galvanized steel/alloy, clay, eco-concrete)

- Size, thickness, and unique pattern/shapes (CNC-precision up to ±0.5mm)

- Surface finish (glazing, IR reflectivity, sanded, matte)

- Color matching and architectural profiles (Pantone matching available)

- Mounting systems (self-locking, windproof, ventilated designs)

- Branding, RFID tracking, and logo embossing

8. Application Scenarios & Case Studies

-

Petrochemical Facility, Guandong: Used anti-corrosive glazed Roof Tiles for 114,000㎡ roof, withstanding acid gases and temperature variations (±60°C).

Result: Reduced maintenance costs by 38% over 8 years. -

High-Speed Railway Stations, Xinjiang: Adopted Roof Tiles with custom colors matching regional aesthetics. Tiles passed all EN 490 wind-uplift and freeze-thaw tests.

Result: No detected leaks or cracks after 6 winters. -

Metropolitan Hospital, London: Installed low absorption ceramic Roof Tiles on 21,000㎡ roof, exceeding BS EN 1304 rainfall penetration standards.

Result: Maintained original color >95% after 5 years. -

Urban Eco-housing Project, Brazil: Integrated IR-reflective Roof Tiles to lower roof surface temperature by 12°C in peak sun.

Result: Reduced HVAC energy costs by 27% (refer: ResearchGate study).

9. Quality Assurance & Standard Compliance

- All Roof Tiles are tested per ISO 10545, ISO 13006, and EN 490 (see ISO Standards).

- Supplier holds ISO 9001:2015, RoHS, and CE certificates.

- Audited & trusted by enterprises: Aramco, Sinopec, GE Construction, Siemens Real Estate.

- 18 years of worldwide project service experience.

10. FAQ: Professional FAQ on Roof Tiles

A: High-purity ceramic, natural clay, galvanized steel (per ASTM A653), and eco concrete are most common. Each ensures a unique balance of strength, weight, and weatherproofing.

A: Key standards include ISO 9001 for quality systems, EN 490/EN 1304 for performance, and ANSI Z97.1 for safety. Surface coating is certified per ISO 14001.

A: For ceramics, ≤6%; for clay, 6–9%; steel/concrete, 0–5% (ISO 10545 guidelines).

A: EN 490 and ASTM C1222 prescribe wind-uplift, overlap, and fastening requirements. Proper underlayment and venting per NRCA guidelines is essential.

A: Glazed finishes increase water resistance and longevity, while matte/sanded reduce surface glare and are recommended for high glare areas.

A: Quality Roof Tiles last 40–60 years for ceramics, up to 80 years for premium clay, and 30–50 years for galvanized products (see data above).

A: Yes, clay and ceramic tiles are 100% recyclable. Metal tiles are remelted for use, complying with ISO 14021 eco-label standards.

11. Customer Support & Trust

- 24/7 technical support via phone, email, and on-site assistance

- All Roof Tiles delivered with batch QA reports and traceable codes

- Free sample policy for architectural projects & B2B clients

- All installations covered under insurance and technical guarantee

References / Further Reading:

[1] National Roofing Contractors Association, Roof Tiles, 2024

[2] ISO Standardization: ISO 10545–2018

[3] Journal of Materials in Civil Engineering, “Performance Benchmarking for Clay and Concrete Roof Tiles” (ASCE Library)

[4] Roofing Industry Forum, RoofingContractor.com, Latest Trends

[5] Energy-saving Impact by Reflective Tiles, ResearchGate Study

For product inquiries, visit: Roof Tiles Official Website

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025