-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Juil . 05, 2025 05:39 Back to list

High-Quality PVC Coated Wire Mesh Fence – Durable, Rustproof & Easy Installation Exporter/Manufacturer

- Introduction to PVC Coated Wire Mesh Fence and Current Market Trends

- Technical Advantages and Material Specifications

- How Major Exporters and Manufacturers Differ in Offerings

- Customization Solutions for Diverse Project Requirements

- Representative Application Case Studies and Performance Analysis

- Comparative Overview: Leading Suppliers and Price/Quality Data

- Why Choose a Reliable PVC Coated Wire Mesh Fence Partner

(pvc coated wire mesh fence)

Introduction: Understanding the Role of PVC Coated Wire Mesh Fence

PVC coated wire mesh fence has gained significant traction within the global security and fencing market due to its blend of strength, corrosion resistance, and visual appeal. Over the past decade, annual demand has grown by approximately 7.6%, with a market value reaching USD 1.2 billion in 2023, according to recent industry analysis. The usage spans sectors such as agriculture, residential, industrial, and transportation.

Globally, more than 58% of fencing installations in high-humidity or industrial environments now specify PVC coated mesh, reflecting its reliability in challenging conditions. Additionally, export demands contribute to a robust supply chain, with top regions including North America, Western Europe, and parts of Asia-Pacific. This introduction highlights not only its growing usage but also sets the stage for a deeper exploration of its technical distinctions, the supplier ecosystem, and application versatility.

Technical Advantages and Material Specifications

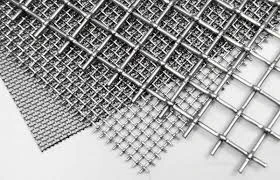

The fundamental advantage of a PVC coated wire mesh fence lies in its layered construction. The galvanized steel core ensures tensile strength—routinely tested to exceed 400 N/mm²—while the extruded PVC coating provides a resilient, UV-resistant surface, extending product lifespans by up to 20 years in exposed environments. Thickness options range from 3.0mm to 5.0mm, with mesh openings typically available in 50x50mm and 60x60mm grids.

Fire safety and chemical resistance are also notable. Quality fences undergo salt spray testing over 1000 hours, evidencing their capacity to resist both saline corrosion and aggressive industrial atmospheres. Colour customization—commonly in green (RAL 6005), black (RAL 9005), or white (RAL 9010)—enhances both aesthetic and compliance flexibility. The integration of anti-climb, anti-cut, and double wire structures further sets apart premium products from generic alternatives.

Industry-leading fencing meets international standards such as EN 10223-7 and ASTM F668, with coating adhesion tested to exceed 150gf/cm. This ensures that buyers—and end users—receive a security solution delivering dependable, long-term value irrespective of local climatic or operational challenges.

Differences Among Exporters, Manufacturers, and Suppliers

The global supply chain for PVC coated wire mesh fence is populated by a spectrum of providers: from manufacturers controlling the entire process (raw wire, galvanizing, coating, assembly) to trading companies and specialized exporters. Understanding these differences can be crucial for procurement managers and project planners.

Manufacturers typically invest in automated production lines with real-time quality monitoring, ensuring mesh uniformity and coating consistency. Leading exporters add value through advanced packaging, logistical coordination, and compliance documentation for cross-border shipments. Suppliers may operate as regional hubs, focusing on inventory availability and rapid delivery.

Procurement cost structures also vary. Statistics from the International Fencing Federation (IFF) show manufacturers’ direct pricing can be up to 18% more cost-effective than middle-tier traders. On the other hand, top-tier exporters offer bundled services such as OEM labeling, project-specific certifications, and after-sales support, adding commissioning or site-integrated analytics for enterprise clients.

| Provider Type | Key Strengths | Average Lead Time | Price Range (USD/m²) | Common Services |

|---|---|---|---|---|

| Manufacturer | Direct control, cost efficiency, quality assurance | 15-25 days | $5.00–$8.00 | OEM production, bulk orders |

| Exporter | Logistics optimization, compliance handling | 18-30 days | $5.50–$9.50 | Custom packaging, documentation |

| Supplier | Inventory access, rapid local delivery | 3–7 days | $6.50–$12.00 | Small batches, technical support |

Customization Solutions Tailored to Project Demands

Customizable options for PVC coated wire mesh fence go well beyond surface colour and mesh size. Leading suppliers provide end-to-end consultation, utilizing parametric design software for project-specific requirements such as terrain adaptation, unique post systems, and security enhancements like razor wire topping or sensor integration.

For infrastructure projects—e.g., expressway boundaries or data center perimeters—fencing can be fabricated with integrated cable conduits, pedestrian gates, or compatibility with access control electronics. The trend toward smart fencing enables seamless upgrades, such as alarm sensors or CCTV mounting, which 47% of surveyed security contractors identified as a primary purchasing criterion in 2023.

Durability can be tuned as well. By selecting higher-micron zinc coatings pre-PVC application, weather exposure ratings can be customized, reaching up to C5-M (very high, marine exposure) as per ISO 12944. These choices ensure that the final solution is not only functional but also cost-optimized and lifecycle-conscious, dovetailing with broader architectural and operational needs.

Application Case Studies: Real-World Performance

To highlight practical performance, several real-world case studies illustrate the versatility of PVC coated wire mesh fence in diverse climates and application scenarios:

- Agricultural Perimeter, Central Germany (2022): More than 12,000 meters of green PVC coated mesh were installed around farmlands. After 24 months, post-inspection found less than 1.5% coating degradation, compared to 6-8% with painted wire mesh in adjacent fields. Vandalism and rust reports were almost eliminated versus prior installations.

- Logistics Park, Southeastern U.S. (2023): A 4.5-meter-high fence, integrating anti-climb mesh and concrete base, withstood two major hurricanes with zero breaches. Insurer reports recognized the fence as a critical loss prevention measure, reducing annual premiums by 12% for property owners.

- Urban Transit Infrastructure, Southeast Asia (2021): Custom-fabricated black PVC coated panels with integrated surveillance lines secured 14km of metro rail. System integration reduced on-site construction time by 28%, as recorded in project audits.

Performance data consistently highlights that initial investment premiums (typically 10-15% higher than bare wire mesh) are offset by dramatic reductions in ongoing maintenance, vandalism repair, and replacement cycles.

Comparative Analysis: Top Suppliers, Pricing, and Quality Benchmarks

Navigating a large supplier pool requires robust comparison across technical parameters, price points, and reliability indices. The following table summarizes recent benchmarks among leading PVC coated wire mesh fence exporter and manufacturer portfolios (2024 update):

| Supplier | Production Capacity (tons/month) | Coating Thickness (mm) | ISO Certification | Warranty (years) | Avg. Export Price (USD/m²) |

|---|---|---|---|---|---|

| TopGuard Fencing Ltd. | 800 | 0.40–0.60 | ISO 9001, 14001 | 15 | $6.20 |

| MeshWorld Industries | 1000 | 0.50 | ISO 9001 | 12 | $5.90 |

| SecureLine Exporters | 650 | 0.45 | ISO 9001, 45001 | 10 | $6.50 |

| GreenMesh Tech | 900 | 0.55 | ISO 14001 | 17 | $6.80 |

Factors such as actual coating thickness, adherence to ISO standards, and warranty conditions are primary indicators of long-term value. Survey results from industry procurement heads favor suppliers documenting full traceability of materials plus third-party testing, trends that continue to influence best practices.

Why Partner with a Trusted PVC Coated Wire Mesh Fence Provider

In selecting a PVC coated wire mesh fence partner, buyers—and end-users—benefit from prioritizing compliance, transparency, and documented manufacturing protocols. Top-tier suppliers not only ensure consistent product quality, but also support project customization, timely after-sales service, and full regulatory compliance.

The consequences of opting for low-bid, non-certified solutions can be severe, from premature corrosion and structural failures to regulatory penalties. With over 65% of major infrastructure projects now stipulating traceability and ISO-compliant security barriers, quality assurance has become a non-negotiable standard.

As the market continues expanding, working with an established pvc coated wire mesh fence

exporter, manufacturer, or supplier secures both the immediate goals of installation and the long-term interests of clients—delivering assets that protect property, people, and reputations well into the future.

(pvc coated wire mesh fence)

FAQS on pvc coated wire mesh fence

Q: What is a PVC coated wire mesh fence?

A: A PVC coated wire mesh fence is a steel fence coated with durable polyvinyl chloride for enhanced weather resistance and longevity. It is widely used for security, garden, and industrial fencing. The PVC layer adds extra protection against corrosion.Q: How do I find a reliable PVC coated wire mesh fence exporter?

A: Look for exporters with verified credentials and positive customer reviews specializing in PVC coated wire mesh fences. Check their compliance with international standards and ability to provide documentation. Request samples or certifications for assurance.Q: What are the benefits of buying from a PVC coated wire mesh fence manufacturer directly?

A: Purchasing directly from a manufacturer ensures competitive pricing and better quality control. Manufacturers can also provide customized solutions tailored to your needs. It often leads to improved communication and after-sales support.Q: How can I choose the best PVC coated wire mesh fence suppliers?

A: Compare multiple suppliers on product quality, lead time, and price. Check if the suppliers offer installation guidance and after-sales services. Reliable suppliers should also have a proven track record in international trade.Q: Are PVC coated wire mesh fences suitable for outdoor use?

A: Yes, PVC coated wire mesh fences are ideal for outdoor use due to their rust and corrosion resistance. The PVC coating protects the underlying metal from weather damage. They are perfect for gardens, parks, and industrial sites.-

High-Quality Horse Fence Wire – Reliable Manufacturer, Exporter & Suppliers

NewsJul.05,2025

-

Premium Annealed Black Wire - Leading Black Annealed Wire Manufacturers & Exporters

NewsJul.05,2025

-

High-Quality PVC Coated Wire Mesh Fence – Durable, Rustproof & Easy Installation Exporter/Manufacturer

NewsJul.05,2025

-

High Quality Galvanized Wire 3mm - Leading Manufacturer, Exporter & Supplier

NewsJul.04,2025

-

High-Quality Security Fence Supplier & Manufacturer Leading Exporter

NewsJun.24,2025

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025