-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Août . 28, 2025 02:00 Back to list

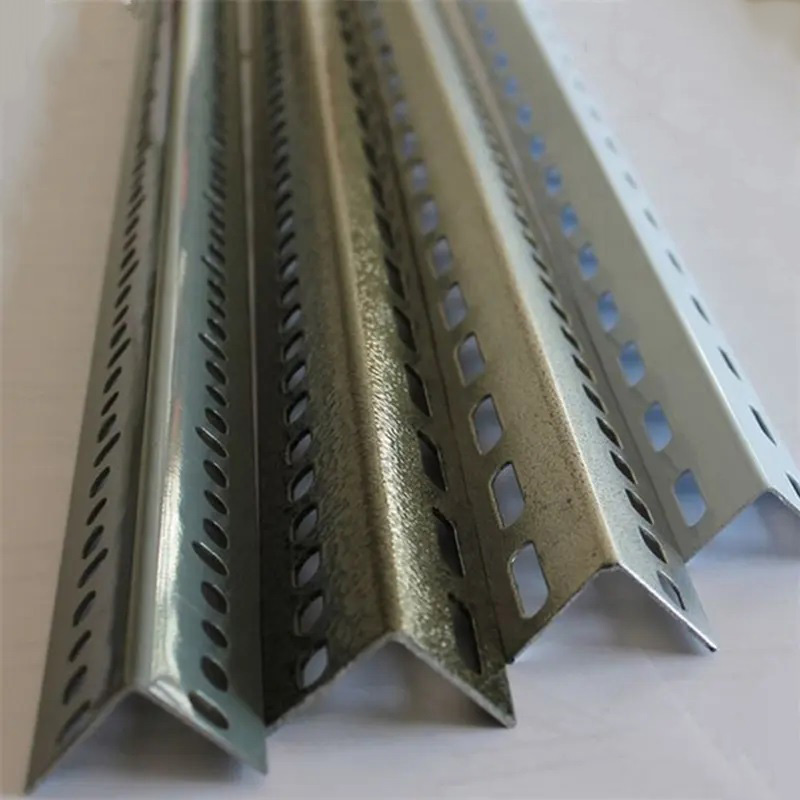

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

Navigating the Landscape of High-Performance Stainless Steel Angle Manufacturing

The demand for robust, corrosion-resistant, and versatile structural components continues to grow across myriad industrial sectors. In this context, the role of stainless steel angle factories is paramount, serving as the backbone for critical infrastructure and precision engineering applications. These specialized manufacturers are at the forefront of producing angle hole and angle bar products that meet stringent technical specifications and operational demands. Understanding the intricate processes, technical advantages, and vendor considerations is crucial for B2B decision-makers seeking reliable and high-quality stainless steel solutions.

This comprehensive guide delves into the core aspects of the stainless steel angle industry, from manufacturing intricacies to application advantages and vendor selection. We aim to provide an authoritative resource for engineers, procurement managers, and project developers, illuminating the expertise, experience, and trustworthiness that define leading stainless steel angle factories.

Current Industry Trends and Market Dynamics

The global market for stainless steel products, including angle sections, is experiencing sustained growth driven by urbanization, infrastructure development, and increased industrial output. Key trends impacting stainless steel angle factories include:

- Sustainable Manufacturing: A growing emphasis on eco-friendly production processes, energy efficiency, and waste reduction in steel manufacturing.

- Advanced Alloys: Development and adoption of new stainless steel grades (e.g., Duplex, Super Duplex) offering enhanced corrosion resistance and strength, particularly for harsh environments.

- Digitalization and Automation: Integration of Industry 4.0 technologies, such as IoT, AI, and advanced robotics, for improved production efficiency, quality control, and supply chain management. This allows leading steel slotted angles manufacturers to optimize their output.

- Customization: Increased demand for tailor-made angle sections, including specific hole patterns, lengths, and finishes, necessitating flexible production capabilities from stainless steel angle factories.

- Global Supply Chain Resilience: Efforts to diversify supply chains and mitigate risks, impacting sourcing strategies for raw materials and distribution networks for finished products from stainless steel angle factories and stainless steel angle suppliers.

These trends underscore the dynamic nature of the industry and the continuous innovation required to remain competitive and meet evolving client needs.

The Manufacturing Process: Precision from Raw Material to Finish

The production of stainless steel angles involves a series of meticulously controlled stages, ensuring the final product meets exact dimensional and metallurgical specifications. Leading stainless steel angle factories adhere to rigorous quality protocols throughout this process.

1. Raw Material Selection and Preparation

The foundation of a high-quality stainless steel angle lies in the raw material. Typically, high-grade stainless steel billets (e.g., AISI 304, 316, 316L for austenitic grades; 430 for ferritic grades; 2205 for duplex grades) are sourced. These materials are chosen for their specific properties: 304 for general-purpose corrosion resistance, 316/316L for enhanced resistance to chlorides and acidic environments, and duplex for superior strength and corrosion resistance. Chemical composition is verified against ASTM A276 or equivalent standards.

2. Primary Forming: Hot Rolling

The most common method for producing stainless steel angles is hot rolling. Billets are heated to high temperatures (typically 1100-1250°C) to make them malleable. They are then passed through a series of rolling mills, gradually reducing their cross-section and forming the characteristic L-shape. This process refines the grain structure, enhancing mechanical properties. The hot-rolled products, often referred to as steel slotted angles, offer robust structural integrity.

3. Secondary Forming and Finishing

- Cold Forming (for smaller, precision angles): For smaller or more precise angles, cold forming techniques like cold bending or cold drawing may be used, which offers tighter tolerances and improved surface finish but less ductility than hot rolling.

- Punching/Drilling (for Angle Hole products): Specialized CNC machinery is employed for precise punching or drilling of holes according to client specifications. This ensures accurate alignment and consistent hole dimensions, crucial for modular assembly. This is where the "angle hole" designation comes from, showcasing the versatility of stainless steel angle factories.

- Cutting and Straightening: Angles are cut to specified lengths using high-precision saws or shears and then straightened to ensure flatness and angular accuracy.

- Pickling and Passivation: To remove scale and impurities from the rolling process and enhance corrosion resistance, angles undergo pickling (acid cleaning) and passivation (forming a passive chromium oxide layer).

4. Quality Control and Testing Standards

Throughout the manufacturing cycle, rigorous testing is conducted to ensure compliance with international standards such as ISO 9001 (Quality Management), ASTM A484/A484M (General Requirements for Stainless Steel Bars, Billets, and Forgings), and relevant ANSI specifications. Key tests include:

- Chemical Analysis: Verification of alloy composition using spectrometers.

- Mechanical Testing: Tensile strength, yield strength, elongation, and hardness tests (Brinell or Rockwell) to assess structural integrity.

- Dimensional Inspection: Precise measurement of leg length, thickness, angularity, and hole spacing.

- Surface Finish Inspection: Visual and instrumental checks for defects, scale, and surface roughness.

- Non-Destructive Testing (NDT): Ultrasonic testing, dye penetrant inspection, or eddy current testing for internal flaws where critical.

This meticulous process ensures that products from a reputable stainless steel angle factory offer an extended service life, often exceeding 50 years in benign environments, and demonstrating exceptional corrosion resistance and mechanical strength crucial for demanding industries like petrochemical and metallurgy.

Figure 1: Hot rolling process for stainless steel angles at a leading factory.

Technical Specifications and Product Parameters

Understanding the key technical parameters is essential for specifying the correct stainless steel angles for any project. Leading stainless steel angle factories provide comprehensive data sheets covering these aspects.

Typical Product Specifications (Angle Hole / Angle Bars)

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material Grades | Austenitic (304, 304L, 316, 316L), Duplex (2205), Ferritic (430) | ASTM A276, EN 10088-3 |

| Leg Length (A x B) | Equal or Unequal, external dimensions of the angle legs | 20mm x 20mm to 200mm x 200mm |

| Thickness (t) | Material thickness of the angle legs | 2mm to 20mm |

| Standard Lengths | Common stock lengths; custom lengths available | 4m, 6m, 6.1m (20ft), 12.2m (40ft) |

| Hole Type / Pattern | Round, square, slotted; custom patterns for angle hole bars | Diameters from 6mm to 25mm |

| Surface Finish | Mill finish, pickled & annealed, polished (e.g., #4, #8 mirror) | According to ASTM A480 |

| Tolerance | Dimensional and angular accuracy | Conforms to ASTM A484/A484M, EN 10056-2 |

These specifications are crucial for ensuring interoperability and structural integrity, especially for complex assemblies. Stainless steel angle suppliers must provide clear documentation for each batch of material.

Application Scenarios and Target Industries

The versatility of stainless steel angles makes them indispensable across a broad spectrum of industries, primarily due to their superior corrosion resistance, high strength-to-weight ratio, and aesthetic appeal. Stainless steel angle factories cater to diverse market segments.

Figure 2: Stainless steel angles used in a water treatment facility.

- Petrochemical and Chemical Processing: In environments exposed to aggressive chemicals, acids, and high temperatures, stainless steel angles provide critical structural support for pipelines, platforms, and storage tanks. Their inherent corrosion resistance ensures long-term integrity and minimizes downtime, offering significant energy saving advantages by reducing the need for frequent replacements.

- Metallurgy and Mining: Used in conveyor systems, scaffolding, and structural frameworks within smelters and processing plants where resistance to abrasive materials and harsh conditions is crucial. Products from a reliable steel slotted angles manufacturer are vital here.

- Water Supply & Drainage Systems: For wastewater treatment plants, desalination facilities, and water distribution networks, stainless steel angles form robust support structures for tanks, filters, and piping, resisting corrosion from water and various effluents.

- Food & Beverage Processing: The hygienic properties of stainless steel, coupled with its ease of cleaning, make angles ideal for frames, racks, and supports in food preparation areas, adhering to strict sanitation standards.

- Architectural and Construction: Used for decorative elements, structural reinforcement, balustrades, and window frames, particularly in coastal or high-humidity regions where atmospheric corrosion is a concern.

- Marine and Offshore: Due to their excellent resistance to saltwater corrosion, stainless steel angles are used in ship construction, offshore platforms, and marine infrastructure.

- Aerospace and Transportation: Lightweight yet strong, they are utilized in specific components requiring high performance and durability.

The perforated or slotted angle bars from steel slotted angles suppliers simplify assembly and offer modularity, which is particularly beneficial in these diverse applications.

Technical Advantages of Stainless Steel Angle Products

Choosing stainless steel angles offers distinct technical advantages over other materials, making them a preferred choice for demanding applications. These benefits are a direct result of the inherent properties of stainless steel alloys and the precision manufacturing capabilities of stainless steel angle factories.

- Superior Corrosion Resistance: The primary advantage is the formation of a passive chromium oxide layer, protecting the steel from rust and various corrosive agents. Different grades offer varying levels of resistance to pitting, crevice corrosion, and stress corrosion cracking. This property is crucial for applications in harsh outdoor, marine, or chemical environments.

- High Strength and Durability: Stainless steel offers excellent tensile and yield strength, providing robust structural support without excessive bulk. This contributes to longer service life and reduced maintenance, representing significant energy saving in the long run.

- Heat Resistance: Certain stainless steel grades (e.g., 310S) maintain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications.

- Hygienic Properties: The non-porous surface of stainless steel resists bacterial growth and is easy to clean, making it ideal for pharmaceutical, food, and medical industries.

- Aesthetic Appeal: Stainless steel angles provide a clean, modern, and high-quality finish, often used in architectural and design-conscious applications. Various surface finishes (e.g., polished, brushed) can be achieved.

- Recyclability: Stainless steel is 100% recyclable without degradation, contributing to sustainable engineering practices.

These combined advantages underscore why steel slotted angles manufacturers are increasingly relied upon for critical structural components.

Vendor Comparison: Selecting the Right Partner

Choosing the right stainless steel angle factory or supplier is a critical decision impacting project success, cost-efficiency, and long-term reliability. A careful comparison helps identify the best steel slotted angles exporter or steel slotted angles supplier for your specific needs.

Key Comparison Factors for Stainless Steel Angle Suppliers

| Factor | High-Quality Vendor | Typical Vendor |

|---|---|---|

| Certifications & Standards | ISO 9001, ASTM, EN, PED (Pressure Equipment Directive) compliant; full material traceability. | Basic quality certificates; limited traceability. |

| Product Range & Customization | Extensive stock, custom dimensions, hole patterns, finishes; engineering support. | Limited standard sizes; minimal customization options. |

| Quality Control & Testing | In-house lab, comprehensive mechanical, chemical, NDT testing; detailed test reports. | Reliance on external labs or basic internal checks. |

| Lead Time & Logistics | Reliable, communicated lead times; efficient global logistics network for steel slotted angles exporters. | Inconsistent delivery; potential for delays. |

| After-Sales Support | Responsive technical support, warranty, clear return policy, problem resolution. | Limited or no post-sale assistance. |

| Experience & Reputation | Years in business, strong industry reputation, client testimonials, repeat business. | Newer to market or less established track record. |

Partnering with an experienced stainless steel angle factory ensures not only product quality but also reliability, technical support, and adherence to project timelines. Reputable steel slotted angles manufacturers are transparent about their processes and capabilities.

Customized Solutions and Design Flexibility

Modern industrial applications frequently require more than off-the-shelf components. Leading stainless steel angle factories excel in providing customized solutions, enhancing design flexibility and project-specific optimization. This includes:

- Tailored Dimensions: Production of angles with non-standard leg lengths, thicknesses, and precise cut lengths to minimize waste and fabrication time on-site.

- Custom Hole Patterns: Designing and punching specific hole configurations (diameters, spacing, shapes) for seamless integration with existing structures or unique assembly requirements, a hallmark of advanced angle hole bar manufacturing.

- Special Alloys and Finishes: Working with less common stainless steel grades (e.g., higher nickel alloys for extreme conditions) or applying specialized surface treatments (e.g., electropolishing for ultra-hygienic applications).

- Pre-Fabrication Services: Some steel slotted angles factory operations offer additional services like welding, bending, and assembly of complex structures, reducing the need for multiple vendors.

- Engineering Consultation: Offering expertise in material selection, structural analysis, and design optimization to ensure the customized solution meets performance criteria and cost objectives.

This capability is particularly valuable for complex engineering projects where standard components may not suffice. Experienced stainless steel angle suppliers work closely with clients to develop optimal solutions.

Real-World Application Case Studies

Examining practical applications demonstrates the tangible benefits and proven reliability of stainless steel angles from specialized stainless steel angle factories.

Case Study 1: Offshore Oil & Gas Platform

A major energy company required structural angles for a new offshore platform in the North Sea. The conditions were extremely challenging, involving constant exposure to saltwater, high winds, and corrosive atmospheric elements. A reputable stainless steel angle factory supplied custom-fabricated Duplex 2205 stainless steel angles (AISI S31803) with specific hole patterns for modular assembly. The material's superior pitting and crevice corrosion resistance, combined with higher tensile strength compared to austenitic grades, significantly extended the platform's service life and reduced maintenance intervals. The project benefited from precise lead times and comprehensive material certifications from the steel slotted angles factory.

Figure 3: Stainless steel angles providing structural integrity in an industrial setting.

Case Study 2: Municipal Wastewater Treatment Plant

A municipal authority undertook an upgrade of its wastewater treatment facilities, requiring robust and corrosion-resistant support frameworks for clarifiers, aeration tanks, and chemical dosing systems. Standard carbon steel angles would rapidly degrade in the highly corrosive environment. A trusted stainless steel angle factory provided large quantities of 316L stainless steel angles, including numerous pre-punched angle hole bars. The decision was based on 316L's enhanced resistance to chlorides and its proven performance in similar applications. The customized angle hole bars facilitated rapid, bolt-together assembly, dramatically cutting installation time and labor costs. The factory's adherence to ISO standards and provision of comprehensive test reports ensured complete compliance with regulatory requirements.

Ensuring Trustworthiness and Authoritativeness

For B2B procurement, trust and authoritativeness are paramount. Leading stainless steel angle factories build this through transparent practices, robust quality systems, and demonstrable expertise.

Certifications and Adherence to Standards

- ISO 9001: A fundamental certification ensuring a consistent quality management system.

- ASTM & EN Standards: Compliance with international material and dimensional specifications (e.g., ASTM A276, ASTM A484/A484M, EN 10088-3, EN 10056-2) guarantees product interoperability and performance.

- PED (Pressure Equipment Directive): Relevant for components used in pressure systems, ensuring safety and compliance within the EU.

- Material Test Certificates (MTCs): Provision of 3.1 or 3.2 MTCs (EN 10204) for full traceability of chemical composition and mechanical properties from melt to finished product.

Client Partnerships and Industry Standing

Years of service, long-term partnerships with major engineering firms, and a portfolio of successfully completed projects are indicators of an authoritative stainless steel angle factory. Look for evidence of consistent supply to critical industries and positive customer feedback.

Frequently Asked Questions (FAQ)

Here are answers to common questions posed to stainless steel angle factories and stainless steel angle suppliers.

Figure 4: Detailed inspection of stainless steel angle quality.

-

Q1: What is the typical lead time for custom stainless steel angles?

A1: Lead times vary based on complexity, quantity, and current production schedules. For standard items, it can be 2-4 weeks. For highly customized products or large volumes, it may range from 6-12 weeks. Reputable stainless steel angle factories provide accurate estimates upon inquiry and maintain transparent communication.

-

Q2: What warranty is offered on your stainless steel angle products?

A2: Our products typically come with a standard 1-year warranty against manufacturing defects and material failures under normal operating conditions. Extended warranties may be available depending on the product and application. Specific warranty terms are provided with each quotation.

-

Q3: Can you ship products internationally?

A3: Yes, as experienced steel slotted angles exporters, we have extensive experience with international logistics. We work with trusted freight forwarders to ensure efficient and compliant delivery worldwide, handling customs documentation and packaging for overseas transit.

-

Q4: What kind of after-sales support do you provide?

A4: We offer comprehensive after-sales support including technical assistance for installation queries, troubleshooting, and material performance guidance. Our customer service team is available via phone and email during business hours to address any concerns. We are committed to ensuring client satisfaction throughout the product lifecycle.

-

Q5: How do I request a quote for specific stainless steel angles?

A5: Please visit our website's "Contact Us" or "Request a Quote" section. Provide detailed specifications including material grade, dimensions (leg length, thickness), length, quantity, required hole patterns (if applicable), and any specific certifications. Our sales team will respond promptly with a comprehensive proposal.

Conclusion

The selection and procurement of stainless steel angle products demand a detailed understanding of manufacturing processes, technical specifications, and vendor capabilities. Leading stainless steel angle factories distinguish themselves through their commitment to quality, adherence to international standards, capacity for customization, and reliable customer support. By prioritizing expertise, experience, authoritativeness, and trustworthiness, B2B decision-makers can secure the highest quality stainless steel angles, ensuring the longevity and integrity of their critical projects across diverse industrial landscapes.

Citations

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, 10th Edition.

- ASTM International, A276/A276M - 17: Standard Specification for Stainless Steel Bars and Shapes. ASTM, 2017.

- EN 10088-3: Stainless steels - Part 3: Technical delivery conditions for semi-finished products, bars, rods, wire, sections and bright products of corrosion resisting steels for general purposes. European Committee for Standardization, 2014.

- ISO 9001:2015: Quality management systems — Requirements. International Organization for Standardization, 2015.

This is the last article

-

Stainless Steel Angle Factories: Premium Quality & Custom Solutions

NewsAug.28,2025

-

Heavy-Duty Stackable Storage Cages for Efficient Warehouse Storage

NewsAug.27,2025

-

Stainless Steel Wire Mesh: Durable & Corrosion-Resistant Rolls

NewsAug.26,2025

-

Durable Fences: Garden, Pool, Metal & Security Solutions

NewsAug.25,2025

-

Perforated Metal Mesh Sheets: Custom & Wholesale Solutions

NewsAug.24,2025

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025