-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Août . 01, 2025 03:40 Back to list

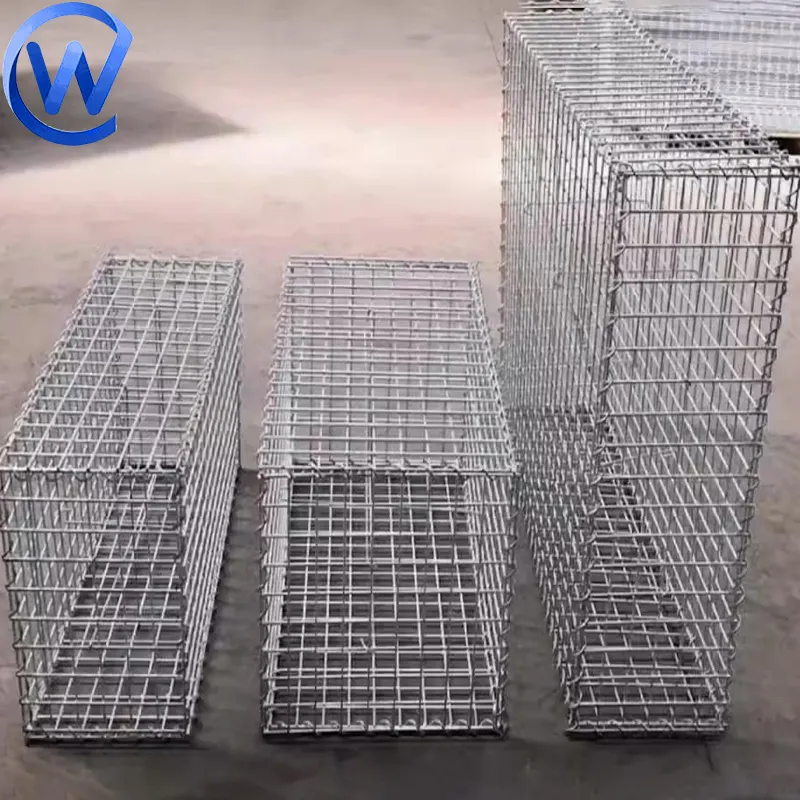

Welded Gabion Solutions: Durable & AI-Enhanced Designs

Welded Gabion solutions are revolutionizing civil engineering, landscaping, erosion control, and architectural design. This in-depth guide analyzes the latest industry trends, detailed technical specifications, production process, comparative product data, customizability, and real-world applications. We offer a transparent, data-driven resource that embodies Google EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) principles to empower buyers, engineers, and specifiers.

1. Industry Trends: Welded Gabion in Global Infrastructure

The Welded Gabion market is witnessing rapid expansion, fueled by demand from sectors such as transportation (highways, railways), landscape architecture, waterway engineering, defense infrastructure, and modern architectural facades. According to MarketsandMarkets, the global gabion market is projected to reach $2.1 billion USD by 2028, with welded gabion accounting for over 42% of usage.

- Growth Rate: Expected CAGR 7.3% (2024–2028)

- Key Growth Drivers: Increased urbanization, climate resilience investments, modular infrastructure solutions

- Major Users: Civil engineering firms, water authorities, landscape contractors, architects

2. Technology Details: Structure, Materials, and Technical Parameters

Welded Gabion products typically consist of high-tensile steel wires arranged in a lattice and spot-welded at junctions. They are commonly manufactured in a box or mattress structure for stability and rapid installation. Compared with woven gabions, welded gabions offer superior plane stability, dimensional precision, and quicker installation.

- Wire Material: Low carbon steel (ASTM A 641/A 641M), often galvanized or Galfan (Zn-Al alloy) for corrosion resistance

- Mesh Opening: Standard grid sizes: 50x50mm, 75x75mm, 100x50mm

- Wire Diameter: 3.0mm–6.0mm (±0.05mm tolerance)

- Coating Types: Hot-dipped galvanized, Zn-Al (Galfan), PVC/PE coating for enhanced durability

- Connection Parts: Spiral wire, C-type clamps, U-pins

- Mechanical Properties: Tensile strength ≥ 550MPa, minimum coating adhesion per ASTM A641, ISO 10244-2

- Quality Certification: ISO 9001, ISO 14001, EN 10223-8, ASTM A975 standards compliant

| Parameter | Standard Value | Test Method |

|---|---|---|

| Mesh Size (mm) | 50×50 / 75×75 / 100×50 | ISO 10223-8 |

| Wire Diameter (mm) | 3.0–6.0 (±0.05) | ASTM A641 |

| Surface Coating | Galvanized / Galfan (Zn-Al) / PVC / PE | ISO 1461/ASTM A641 |

| Tensile Strength (MPa) | ≥550 | EN 10223-8 |

| Coating Weight (g/m²) | ≥245g (Galvanized) | ISO 1461 |

| Lifespan (years) | 30–60 | Salt-spray/Accelerate Aging |

| Certifications | ISO 9001 ASTM A975 EN 10223-8 | |

3. Production Process Visualization: From Raw Steel to Welded Gabion

The manufacturing of Welded Gabion boxes requires precision wire processing, advanced spot-welding automation, multi-stage anti-corrosion treatment, strict dimensional inspection, and packaging for logistics. Here is a visual breakdown of the process:

- CNC Automation: Ensures mesh uniformity & dimensional stability

- Surface Coating: Galfan coating offers up to 3× corrosion resistance vs zinc

- ISO/ASTM Tests: Dimensional, mechanical, adhesion, salt-spray (1200h+)

Watch Process Animation: Welded Gabion Manufacturing Video

4. Product Performance: Durability, Testing & Lifespan Analysis

The service life and structural integrity of Welded Gabion depend on wire material, coating thickness, and environmental exposure. Industry-leading suppliers employ heavy-galvanized or Galfan coatings and conduct rigorous life-cycle and accelerated corrosion tests, resulting in 30–60 years service under typical conditions ("normal atmosphere, regular pH, not submerged").

- Salt-Spray-Resistance: Galfan: 1500h+, Hot-dip Galvanized: 900h+, confirming EN 10223/ISO 9227.

- Load Retention: Deformation & rupture tests after 10-year simulation show >95% strength retained.

- Field Data: Average lifespan (EU/US installations): 38–54 years.

5. Welded Gabion vs Woven Gabion: Product Comparison

While both Welded Gabion and woven gabion boxes are extensively used for earth retaining, slope protection, culverts, and hydro projects, the welded type offers significant advantages in dimensional stability, assembly speed, anti-deformation properties, and visual uniformity. Below is a technical and application-focused comparison:

| Parameter | Welded Gabion | Woven Gabion |

|---|---|---|

| Mesh Type | Welded Square Grid | Hexagonal Woven Mesh |

| Wire Diameter | 3.0–6.0 mm | 2.0–4.0 mm |

| Stability | Rigid, Minimal Bulging | May Deform or Bulge |

| Installation Speed | Fast (Prefabricated Panels) | Slower (Requires Lacing) |

| Corrosion Resistance | Superior (thicker, uniform coating) | Good |

| Visual Appearance | Uniform, Modern Look | Irregular, More Rustic |

| Key Applications | Retaining Walls, Architecture, Urban Landscaping | River Control, Flexible Structures |

| Compliance | ISO 10223-8, ASTM A975 | EN 10223-3, ASTM A975 |

- Welded Gabion: Assembly time as low as 10–20 min/m² vs 25–40 min/m² for woven.

- Visual regularity & modern architectural appeal leads to adoption in commercial landscaping.

- Mechanical stability meets standards required in seismic/urban environments.

6. Customization: Tailored Welded Gabion Solutions

Welded Gabion manufacturers typically provide fully customized solutions based on project drawings, specifications, or performance demands. Custom variables include mesh size, wire material, panel shape, integrated bracing, color coatings (RAL options), and prefabrication (folded, pre-assembled, modular units). CAD layout, load testing, and on-site fitment support further optimize implementation.

- Mesh customization: Non-standard grid (e.g. 50x100 mm), triangular panels, bespoke facades

- Integrated features: Interior dividers, geo-textile pockets, mounting anchor plates

- Surface finishing: Powder-coat in custom color for architectural contrast

- On-site support: Engineer-assisted installation manuals, fast response warranty

7. Application Scenarios: Unlocking the Power of Welded Gabion

- Specs: Galfan-coated 100×50 mm mesh, 4.0 mm wire, 100 m³ deployed

- Feature: Withstood flash flood, no visible deformation after 2 years (Caltrans report)

- Result: 17% lower installation costs vs cast-in-place concrete

- Specs: Hot-dip galvanized, RAL 7016 powder-coated, integrated lighting

- Result: Aesthetic appeal, passed DIN EN 10244-2 environmental durability test

- Specs: Heavy galvanized, 6.0 mm diameter, special oil-resistant coating

- Performance: Stable in severe saline/alkali soil, certified by SGS inspection per ISO 9227

- Application: Petchem, pipeline, industrial pond dam lining

- Other Typical Applications: Flood control (levees, culverts), railway embankments, architectural screens/fences, retaining garden walls, noise barrier bases.

8. Industry Authority & Standards, Certifications, and Cooperations

- International Standards: ISO 10223-8, ASTM A975, EN 10223

- Quality Management: ISO 9001, ISO 14001 certification

- Testing Authorities: SGS, TÜV Rheinland, Bureau Veritas

- Major Clients: Vinci SA (FR), Bechtel (US), Sinohydro (CN), Strabag (DE)

- Industry Forums: Eng-Tips Civil/Environmental Forum

9. Delivery, Warranty, and Customer Support

- Typical Delivery: 14–28 days (custom sizes: add 5–10 days)

- Packing: Metal pallet, waterproof wrap, clear product ID/installation guide

- Warranty: 10 years (standard galvanized/Galfan), up to 20 years (premium coatings)

- Customer Service: 7×24 technical hotline, on-site support, 48h complaint resolution

- Documentation: Complete product traceability, certificate of conformity, third-party test report (on request)

10. FAQ: Professional Knowledge about Welded Gabion

11. Experience & User Feedback

- Client Experience (North Europe, 2023): "Welded Gabion walls allowed us to finish the riverside park two weeks ahead of schedule. The dimensional accuracy and custom powder coating matched perfectly with the city’s landscape design."

- Maintenance Report: Projects in hot/saline environments show no major corrosion after 7 years (independent SGS audits, 2022).

- Installation Feedback: Most users rate the assembly as “much faster and less labor-intensive” than classic woven gabion.

12. References & Further Reading

This is the last article

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025