-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Août . 28, 2024 13:53 Back to list

welded mesh for concrete exporters

Welded Mesh for Concrete Exporters A Growing Market Demand

Welded mesh, commonly used in construction and civil engineering, particularly in concrete applications, has seen a considerable rise in demand in recent years. This increase can be attributed to the rapid expansion of infrastructure development globally. For exporters in the welded mesh industry, understanding market trends, quality standards, and customer needs is essential for tapping into this lucrative market.

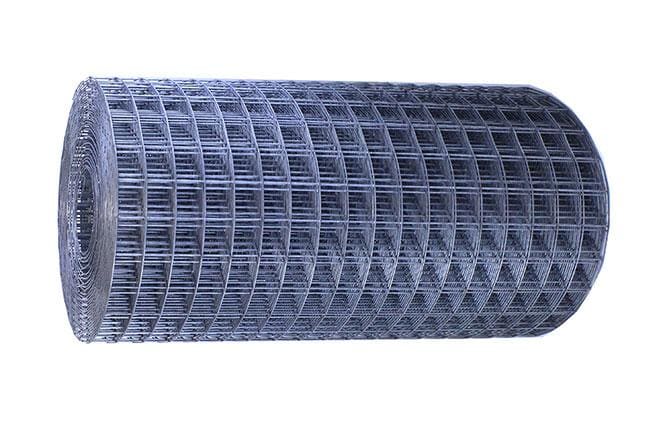

Welded mesh is made from steel wires that are welded together at regularly spaced intervals, forming a grid-like pattern. This product serves multiple purposes in concrete applications, including reinforcement, support, and prevention of cracking. The strength and durability of welded mesh make it an ideal choice for various structures, from residential buildings to large-scale industrial projects.

Welded Mesh for Concrete Exporters A Growing Market Demand

Furthermore, established manufacturers have recognized the importance of adhering to international quality standards. Compliance with standards such as ISO and ASTM is vital to ensure that welded mesh products meet the necessary performance criteria. Exporters must focus on quality control during production, ensuring that their mesh products can withstand the rigors of construction demands, thus gaining the trust of international buyers.

welded mesh for concrete exporters

Another essential aspect for exporters is understanding the preferences of different markets. For instance, some regions may prefer galvanized welded mesh, which offers enhanced corrosion resistance, especially in coastal areas. Other markets may require specific sizes, wire gauges, or spooling options tailored to their localized needs. Adaptability and customization can significantly enhance a supplier’s competitiveness in the global market.

The rise of sustainable construction practices has also influenced the welded mesh sector. Eco-conscious builders increasingly prefer materials that can be recycled or are made from recycled raw materials. Exporters who can demonstrate their commitment to sustainability through eco-friendly production processes will appeal to a growing segment of environmentally aware clients.

Additionally, technological advancements in manufacturing processes have improved the efficiency and cost-effectiveness of producing welded mesh. Adopting innovative techniques, such as automated welding and advanced quality testing, enables exporters to enhance their productivity and reduce waste. This not only helps in keeping prices competitive but also in fulfilling bulk orders quickly, meeting the deadlines of construction projects.

In conclusion, the welded mesh market for concrete has witnessed robust growth, particularly for exporters. By focusing on quality, adapting to regional preferences, and embracing sustainability, suppliers can position themselves advantageously in this dynamic landscape. As the global demand for infrastructure continues to rise, those exporters who innovate and prioritize customer satisfaction will undoubtedly thrive in the competitive international market for welded mesh products. The future looks promising for welded mesh exporters ready to take advantage of these emerging opportunities.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025