-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Agu . 23, 2025 02:00 Back to list

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

Industry Trends and Market Dynamics in Architectural Meshes

The global architectural mesh market is experiencing robust growth, driven by increasing demand for sustainable building materials, innovative aesthetic solutions, and enhanced functional properties in both commercial and residential sectors. Architects and designers are increasingly turning to advanced materials that offer a blend of durability, visual appeal, and performance. A significant trend involves the integration of metallic elements into glass, leading to the rise of specialized products like Metal Mesh Fabric For Glass Laminated. This product category is poised for substantial expansion as it addresses critical needs such as energy efficiency, light control, and security, while simultaneously enabling unprecedented design flexibility.

Key market drivers include urbanization, the increasing adoption of smart building technologies, and stringent environmental regulations promoting green building practices. The demand for materials that can contribute to LEED certification and other sustainability metrics is paramount. Furthermore, the push for unique, customized building facades that reflect corporate identity or artistic vision continues to fuel innovation in the laminated glass and mesh sectors. The fusion of metal and glass provides an elegant, high-performance solution that caters to these evolving architectural and design preferences, setting new benchmarks for aesthetics and functionality in modern construction.

Understanding Metal Mesh Fabric For Glass Laminated

Metal Mesh Fabric For Glass Laminated represents a sophisticated composite material engineered to integrate the strength and aesthetic versatility of metallic meshes with the structural integrity and transparency of glass. This advanced product combines two or more layers of glass with one or more interlayers, typically made of PVB (Polyvinyl Butyral), EVA (Ethylene-vinyl acetate), or SGP (SentryGlas Plus), with the metal mesh fabric encapsulated within. The result is a highly durable, visually striking, and functionally superior panel that finds extensive use in high-end architectural and design applications.

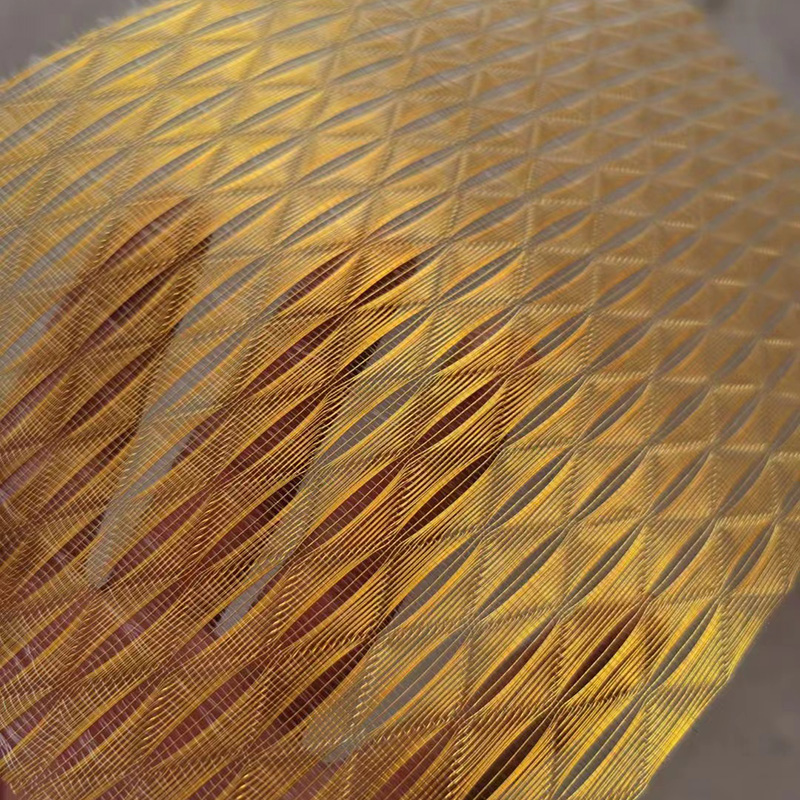

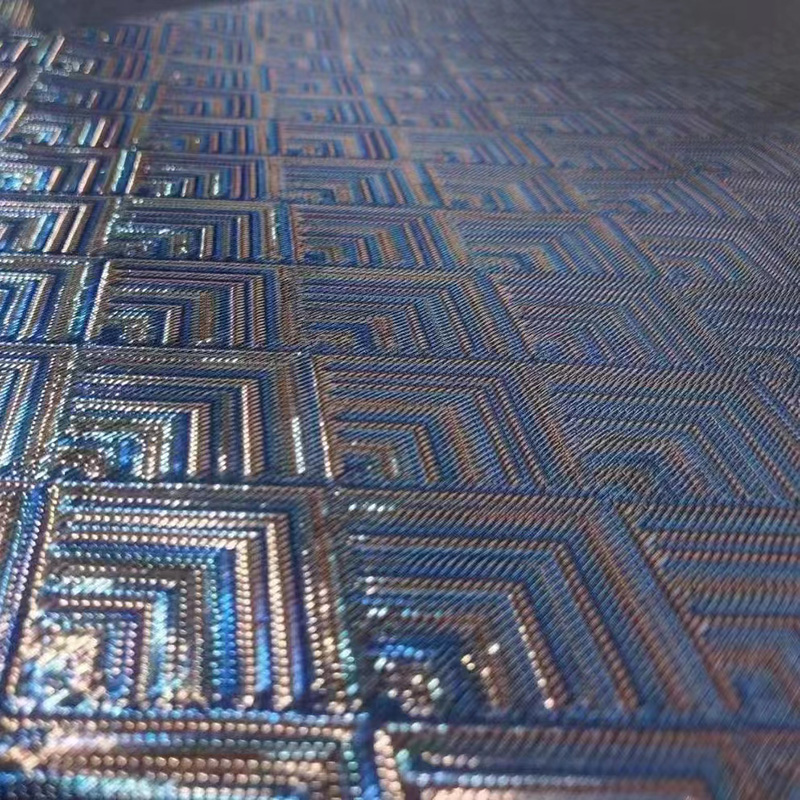

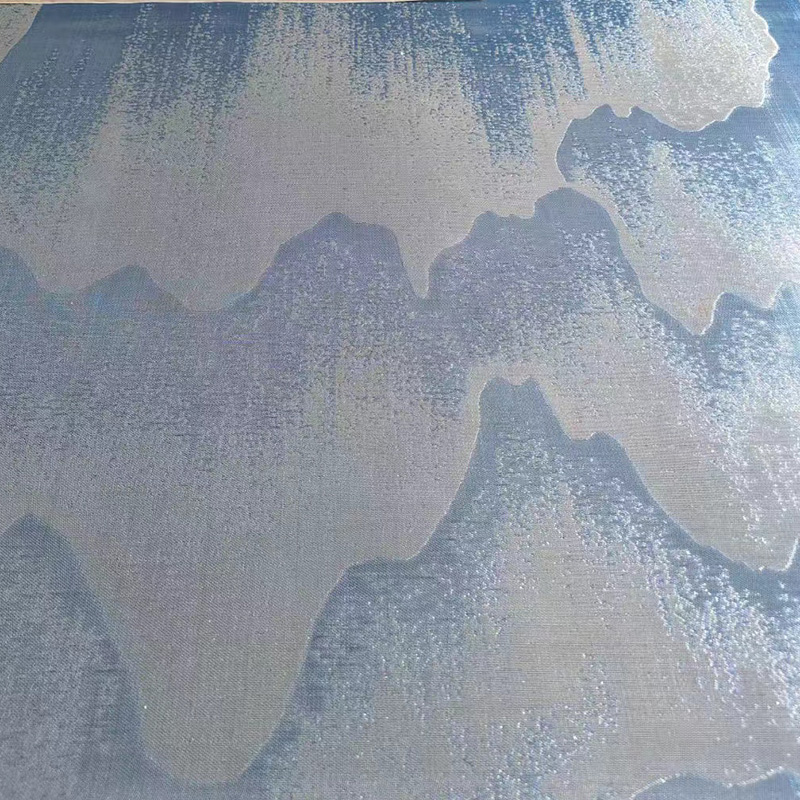

The selection of metal for the mesh is critical, with stainless steel (grades 304, 316, 316L) being the most common due to its exceptional corrosion resistance, strength, and aesthetic appeal. Other materials like brass, copper, bronze, and aluminum are also utilized for specific design requirements, offering distinct colorations and patinas. The mesh itself can be woven in various patterns, including plain weave, twill weave, and specialized decorative weaves, each imparting unique visual textures and light transmission characteristics. The lamination process permanently bonds the mesh to the glass, creating a monolithic structure that enhances safety by holding glass fragments together if shattered, while also providing UV protection, acoustic dampening, and solar control.

Manufacturing Process Flow of Laminated Metal Mesh Glass

The production of Metal Mesh Fabric For Glass Laminated is a meticulous process requiring precision engineering and adherence to strict quality control standards. The typical manufacturing flow involves several critical stages:

1. Material Sourcing and Preparation

- Metal Wire Selection: High-grade metallic wires (e.g., AISI 304, 316, 316L stainless steel, brass, copper) are selected based on desired aesthetic, corrosion resistance, and structural properties. Wire diameters typically range from 0.1 mm to 2.0 mm.

- Glass Selection: Annealed, heat-strengthened, or fully tempered glass panels are chosen. Thickness varies from 3mm to 19mm per layer, depending on application and required impact resistance.

- Interlayer Film: High-performance polymeric films (PVB, EVA, SGP) are prepared. SGP interlayers offer superior stiffness and post-breakage performance compared to traditional PVB.

2. Metal Mesh Fabrication (Weaving/Forming)

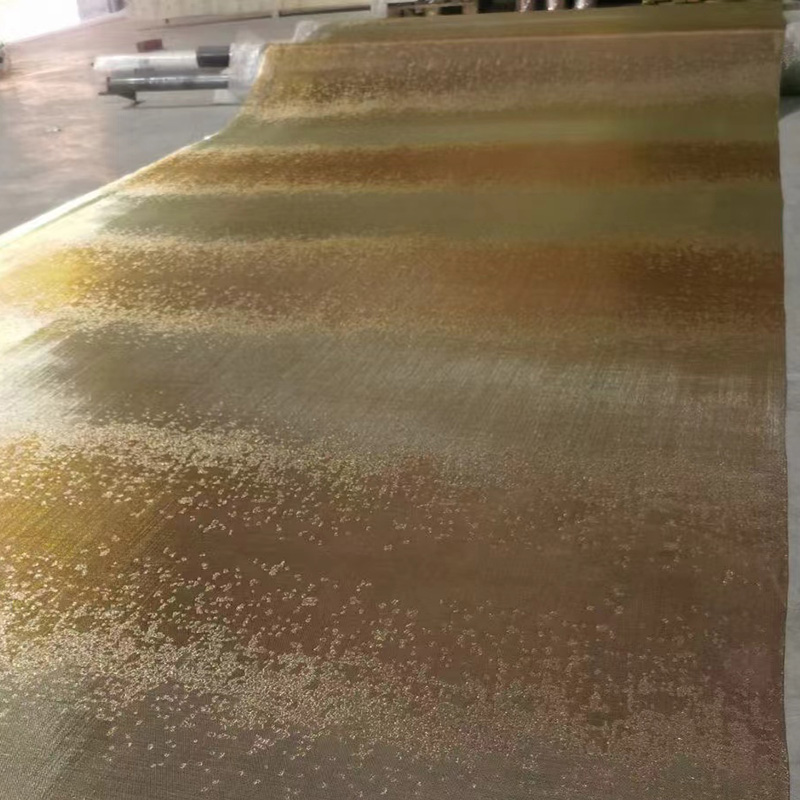

Utilizing specialized weaving looms, metal wires are interwoven to create specific mesh patterns. Common patterns include plain weave (basic warp and weft), twill weave (diagonal pattern), and various crimped or decorative weaves. The open area percentage of the mesh, a critical parameter, is carefully controlled during this stage, influencing light transmission and aesthetic effect. CNC machining might be employed for precise cutting and edge finishing of mesh sheets.

3. Cleaning and Surface Treatment

Both the glass sheets and the metal mesh are meticulously cleaned to remove any dust, oils, or contaminants. This ensures optimal adhesion during the lamination process and prevents visual imperfections. The metal mesh may undergo additional surface treatments, such as passivation for stainless steel, to enhance corrosion resistance or apply specific finishes.

4. Lay-up and Pre-lamination

The components are assembled in a cleanroom environment. Typically, a layer of glass is placed, followed by an interlayer film, the metal mesh, another interlayer film, and finally the second layer of glass. This assembly is then passed through a pre-lamination roller or vacuum bag system to remove trapped air and ensure preliminary adhesion.

5. Autoclave Lamination (Casting/Forging Analogue)

The pre-laminated assembly is placed into an autoclave, where it undergoes a precisely controlled cycle of heat and pressure. This process, analogous to casting or forging in its transformative effect, causes the interlayer material to melt and flow, creating a permanent, transparent bond between the glass layers and encapsulating the metal mesh. The specific temperature and pressure profiles are critical for achieving optimal optical clarity, adhesion, and structural integrity. For certain applications, vacuum lamination ovens may be used as an alternative.

6. Quality Control and Testing

Each laminated panel undergoes rigorous quality checks. This includes visual inspection for defects (bubbles, inclusions, alignment), dimensional accuracy, and adhesion tests. Performance testing is conducted in accordance with international standards such as ISO (e.g., ISO 12543 for Laminated Glass), ANSI Z97.1 (Safety Glazing Materials), and ASTM (e.g., ASTM E1300 for structural integrity of glass). These tests confirm parameters like impact resistance, optical distortion, and delamination resistance. The service life of such products is typically very long, often exceeding 20-30 years in non-aggressive environments, due to the durable materials and encapsulated mesh.

7. Edging and Packaging

Finished panels are edged, cleaned, and carefully packaged to prevent damage during transit. Target industries benefiting from this manufacturing process include high-end architecture, interior design, automotive, and specialized industrial applications such as control room glazing in petrochemical, metallurgy, and water supply & drainage facilities, where enhanced safety and aesthetics are paramount.

Technical Specifications and Performance Parameters

The performance of Metal Mesh Fabric For Glass Laminated is defined by a combination of material properties, weave geometry, and the lamination process itself. Understanding these technical specifications is crucial for specifying the correct product for a given application.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Mesh Material | Stainless Steel (304, 316, 316L), Copper, Bronze, Brass, Aluminum | AISI 316L for high corrosion resistance |

| Glass Type | Annealed, Heat-Strengthened, Fully Tempered | Customizable |

| Interlayer | PVB, EVA, SGP | 0.38mm to 1.52mm thickness |

| Wire Diameter | Diameter of individual metal wires | 0.1 mm - 2.0 mm |

| Mesh Pitch/Opening | Distance between wire centers or opening size | 0.2 mm - 20 mm (or more for decorative) |

| Open Area Percentage | Percentage of light/air allowed through mesh | 10% - 80% (varies by design) |

| Total Glass Thickness | Overall thickness of the laminated panel | 6.76 mm - 40 mm+ |

| Maximum Panel Dimensions | Largest size achievable for a single panel | Up to 3200 mm x 6000 mm (depending on supplier) |

| Light Transmission | Visible Light Transmittance (VLT) | 15% - 70% (mesh dependent) |

| Solar Heat Gain Coefficient (SHGC) | Ability to block solar heat gain | 0.25 - 0.55 (mesh dependent) |

| UV Protection | Blockage of harmful UV rays | >99% (typical for PVB/EVA/SGP) |

| Acoustic Reduction | Sound Transmission Class (STC) rating | Up to 38 dB+ (depending on total thickness and interlayer) |

These parameters directly influence the performance of the laminated glass in terms of energy saving (through controlled solar heat gain), corrosion resistance (via material selection), and overall structural integrity. For instance, an architect might choose a finer mesh with a lower open area for greater solar shading, thus enhancing energy efficiency, or a robust stainless steel mesh for extreme environmental conditions to ensure superior corrosion resistance in coastal or industrial settings.

Versatile Application Scenarios

The unique combination of aesthetics, durability, and functional properties makes Metal Mesh Fabric For Glass Laminated suitable for a broad spectrum of high-demand applications across various industries:

- Architectural Facades and Cladding: Offering dynamic visual effects, solar shading, and weather protection. The material can reduce heat gain, contributing to energy saving in large buildings.

- Interior Partitions and Decorative Walls: Creating elegant, semi-transparent dividers that allow light flow while maintaining distinct spaces.

- Balustrades and Railings: Enhancing safety with robust, impact-resistant panels that also provide a sophisticated aesthetic.

- Elevator Cab Interiors: Adding a luxurious and modern touch to vertical transportation systems, with enhanced scratch and impact resistance.

- Sun Shading and Glare Control: Effectively managing daylight and reducing glare, which significantly improves occupant comfort and energy efficiency.

- Security and Safety Panels: Used in areas requiring increased security, such as banks, government buildings, or industrial control rooms. The laminated structure prevents shattering and maintains integrity upon impact.

- Furniture and Retail Displays: Incorporating metallic textures into high-end furniture and bespoke retail fixtures for a distinctive look.

- Artistic Installations and Public Art: Providing a unique medium for artists to explore light, shadow, and reflection within permanent installations.

- Target Industries: In sectors like petrochemical, metallurgy, and water supply & drainage, this material is increasingly used for control room windows, observation panels, or protective screens where a combination of high visibility, impact resistance, and sometimes corrosion resistance is critical for operational safety and longevity. For instance, in a metallurgy plant, the corrosion resistance of stainless steel mesh within laminated glass ensures the integrity of viewing panels despite exposure to harsh atmospheric conditions.

Technical Advantages and Performance Benefits

The integration of metal mesh into laminated glass panels delivers a compelling suite of technical advantages and performance benefits that surpass conventional glazing solutions:

- Enhanced Structural Integrity and Safety: The laminated structure, especially with an SGP interlayer, provides superior post-breakage performance. In the event of an impact, glass fragments adhere to the interlayer and mesh, reducing the risk of injury. This also contributes to enhanced security against forced entry or vandalism.

- Outstanding Corrosion Resistance: When utilizing high-grade stainless steel (e.g., 316L), the encapsulated mesh is protected from external corrosive agents, making it ideal for coastal environments, chemical processing plants, or areas with high pollution.

- Superior Energy Efficiency: The metallic mesh acts as a natural sunshade, reducing solar heat gain and thus decreasing cooling loads in buildings. This directly translates to significant energy saving and lower operational costs. The combination of glass and mesh also improves the U-value, contributing to better thermal insulation.

- Controlled Light Transmission and Glare Reduction: The mesh weave pattern and open area can be precisely engineered to modulate the amount of visible light entering a space, minimizing glare while maximizing natural illumination.

- UV Radiation Protection: The interlayer material typically blocks over 99% of harmful UV rays, protecting interior furnishings, artwork, and occupants from fading and damage.

- Acoustic Performance: The multi-layered structure of laminated glass with an interlayer provides excellent sound dampening properties, significantly reducing noise transmission, which is beneficial in urban environments or areas requiring sound isolation.

- Unmatched Aesthetic Appeal: The metallic texture and inherent reflectivity of the mesh create dynamic visual effects that change with light conditions, offering architects and designers a unique tool for creating bespoke, high-impact facades and interiors.

- Longevity and Low Maintenance: The robust construction materials and sealed environment of the laminated panel ensure a long service life with minimal maintenance requirements, even in challenging environmental conditions.

Vendor Comparison for Metal Mesh Fabric For Glass Laminated

Selecting the right vendor for Metal Mesh Fabric For Glass Laminated is crucial for ensuring product quality, project success, and long-term satisfaction. Key criteria should be evaluated beyond just initial cost. Below is a conceptual comparison table outlining important factors:

| Evaluation Factor | Leading Supplier (e.g., GalvanizedMeshProducts.com) | Alternative Supplier (General Market) |

|---|---|---|

| Product Expertise & Range | Extensive portfolio of mesh types, materials, and glass configurations; deep technical knowledge. | Limited range, less specialization in exotic materials or complex weaves. |

| Customization Capabilities | Highly flexible for bespoke designs, unique patterns, and large panel sizes; R&D support for new material combinations. | Standard options only, limited ability to deviate from catalog. |

| Certifications & Quality Assurance | ISO 9001, CE, ASTM, ANSI compliance; rigorous in-house testing and third-party verification. | Basic compliance, fewer independent certifications or limited test data. |

| Technical Support & Design Assistance | Dedicated engineering team, CAD/BIM support, on-site consultation, specification guidance. | Sales-focused support, minimal engineering input. |

| Lead Times & Fulfillment | Efficient production, clear communication of lead times, reliable global logistics. | Variable and often longer lead times, less transparent communication. |

| Warranty & After-Sales Service | Comprehensive warranty, dedicated after-sales support, installation guidance. | Limited warranty, minimal post-purchase support. |

A leading supplier will not only provide a superior product but also offer unparalleled service and support, crucial for complex architectural projects where technical precision and timely delivery are paramount.

Customized Solutions and Bespoke Design Integration

Recognizing that every architectural project has a unique vision, providers of Metal Mesh Fabric For Glass Laminated offer extensive customization capabilities. This flexibility is a cornerstone of its appeal in high-end design.

- Mesh Material and Weave Patterns: Clients can specify not only the metal alloy (e.g., 304, 316, 316L, copper, brass) but also intricate weave patterns, wire diameters, and open area percentages to achieve specific aesthetic and functional outcomes (e.g., level of opacity, light reflection, solar performance).

- Glass Type and Configuration: Options include clear, ultra-clear (low-iron), tinted, or acid-etched glass. Thickness, temper (annealed, heat-strengthened, tempered), and edge work (polished, beveled) are all customizable. Multi-layer laminates for enhanced security or acoustic performance are also available.

- Interlayer Technology: Selection of PVB, EVA, or SGP interlayers allows for fine-tuning of mechanical strength, moisture resistance, and post-breakage performance. Special colored interlayers can also be incorporated to add subtle hues to the final product.

- Panel Dimensions and Shapes: Panels can be fabricated to precise dimensions, including oversized and complex shapes (e.g., curves, irregular polygons), accommodating ambitious design schemes.

- Integrated Solutions: Advanced customization includes integration with smart technologies, such as embedded LEDs or thin-film photovoltaics, transforming the glass into an interactive or energy-generating facade.

The collaboration process typically involves close consultation with architects and designers, from initial concept development and material selection to prototyping and final production, ensuring the bespoke solution perfectly aligns with the project's vision and technical requirements.

Application Case Studies and Customer Experience

Real-world applications demonstrate the transformative power of Metal Mesh Fabric For Glass Laminated. Our extensive experience with diverse clients highlights our commitment to delivering high-performance, aesthetically compelling solutions.

Case Study 1: Corporate Headquarters Facade

A major technology firm required a distinctive facade for its new headquarters that would reflect innovation and sustainability. We provided bespoke laminated glass panels incorporating a fine, stainless steel 316L mesh with an open area of 40%. The solution delivered exceptional solar shading, reducing the building's HVAC load by an estimated 18%, while creating a shimmering, dynamic exterior that changed appearance with the ambient light. Customer feedback emphasized the enhanced aesthetic appeal and measurable energy savings.

Case Study 2: High-Security Financial Institution

For a new financial institution building, security was paramount. Our multi-layer laminated glass with a robust mesh and SGP interlayer was specified for all ground-floor glazing. This product provided certified blast and forced-entry resistance, exceeding industry standards (e.g., UL 752 Level 3). The client praised the seamless integration of high security with an elegant, modern design that did not compromise transparency or natural light. "The peace of mind knowing our assets are protected without sacrificing our architectural vision is invaluable," remarked the project manager.

Case Study 3: Coastal Resort Balustrades

A luxury resort located in a highly corrosive coastal environment needed durable yet visually striking balustrades. We supplied laminated glass with 316L stainless steel mesh, chosen for its superior corrosion resistance and ability to withstand saline conditions. The mesh provided a subtle shimmering effect, enhancing the resort's upscale ambiance. The client reported zero degradation or discoloration of the mesh after five years of exposure, a testament to the product's longevity and material quality.

Quality Assurance, Certifications, and Authoritativeness

Our commitment to excellence is underpinned by rigorous quality assurance protocols and adherence to international standards, ensuring that every Metal Mesh Fabric For Glass Laminated panel meets the highest benchmarks for performance and reliability. We are a trusted partner with years of specialized experience in this niche.

- ISO 9001 Certified Manufacturing: Our production facilities operate under ISO 9001:2015 quality management systems, ensuring consistent product quality, continuous improvement, and customer satisfaction.

- Compliance with International Standards: All products comply with relevant global standards, including ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute) Z97.1 for safety glazing, EN (European Standards) 12543 for laminated glass, and AS/NZS (Australian/New Zealand Standards).

- Material Certifications: Raw materials, particularly stainless steel alloys, are sourced from certified mills and come with material test certificates (MTCs) confirming their chemical composition and mechanical properties, ensuring long-term corrosion resistance and structural integrity.

- Performance Test Data: We provide comprehensive test data for our products, including:

- Impact Resistance: Tested to relevant safety glazing standards.

- Wind Load Resistance: Structural performance under various wind pressures.

- Solar Performance: Detailed SHGC, VLT, and UV blockage data.

- Acoustic Performance: Sound Transmission Class (STC) ratings.

- Thermal Stress Resistance: Durability under temperature fluctuations.

- Years of Service and Reputable Client Base: With a decade of dedicated service in the architectural and industrial glazing sector, we have partnered with leading architectural firms, construction companies, and industrial giants on prestigious projects worldwide, building a reputation for reliability and innovation. Our expertise is recognized across target industries from commercial real estate to specialized industrial installations.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with our B2B clients is paramount. We achieve this through transparent processes, clear commitments, and robust support systems for our Metal Mesh Fabric For Glass Laminated products.

Frequently Asked Questions (FAQ)

- Q1: Can your metal mesh laminated glass be used for exterior facades in harsh climates?

- A1: Yes, absolutely. We primarily utilize marine-grade stainless steel (316 or 316L) for mesh fabric, which offers superior corrosion resistance against salt spray, humidity, and industrial pollutants, making it ideal for harsh exterior environments. Our lamination process further protects the mesh.

- Q2: What are the primary benefits of using SGP interlayers over traditional PVB for this product?

- A2: SGP (SentryGlas Plus) interlayers provide significantly higher stiffness and tear strength compared to PVB. This results in superior post-breakage performance, where the glass remains largely intact and rigid even after impact, offering enhanced safety, security, and resistance to wind loads and blasts. It’s ideal for structural glazing and high-security applications.

- Q3: How does the metal mesh contribute to energy efficiency?

- A3: The encapsulated metal mesh acts as an effective solar control device. Depending on the mesh's open area and reflectivity, it can significantly reduce the Solar Heat Gain Coefficient (SHGC), minimizing the amount of solar radiation that enters the building. This decreases the reliance on air conditioning, leading to substantial energy savings.

- Q4: Is customization available for mesh patterns and sizes?

- A4: Yes, extensive customization is a core offering. We can produce a wide array of mesh patterns, wire diameters, and open area percentages. Panels can be fabricated to specific dimensions, including oversized formats and unique shapes, to meet precise architectural and design requirements.

Lead Time and Fulfillment

Standard lead times for our Metal Mesh Fabric For Glass Laminated typically range from 4 to 8 weeks, depending on the complexity of the customization, order volume, and specific material requirements. We maintain a robust supply chain and efficient production scheduling to ensure timely delivery. For urgent projects, expedited manufacturing and shipping options are available upon request and can be discussed with our sales team during the quotation process. All products are meticulously packed for global shipping, ensuring safe arrival at the project site.

Warranty Commitments

We stand by the quality and durability of our products. All Metal Mesh Fabric For Glass Laminated panels are covered by a comprehensive 10-year limited warranty against delamination, material defects, and significant aesthetic degradation under normal use and proper installation. Specific terms and conditions are provided with each project proposal, detailing coverage for materials and workmanship. Our warranty reflects our confidence in the longevity and performance of our advanced glazing solutions.

Customer Support Information

Our dedicated customer support team is available to assist you throughout your project lifecycle. From initial inquiry and technical consultation to post-installation support, we ensure a seamless experience. Our services include:

- Technical Consultation: Expert advice on material selection, design optimization, and compliance.

- Project Management: Dedicated point of contact for project coordination and updates.

- Installation Guidance: Comprehensive documentation and, where required, on-site technical assistance.

- After-Sales Service: Prompt response to any product performance inquiries or warranty claims.

For inquiries, please contact us via the details on our website, or email our support team directly. We are committed to providing the highest level of service and ensuring your project's success.

Conclusion

Metal Mesh Fabric For Glass Laminated represents a pinnacle of innovation in modern glazing, offering an unparalleled blend of aesthetic sophistication, robust performance, and sustainable design capabilities. From enhancing energy efficiency and providing superior security to enabling boundless architectural creativity, this material transcends traditional building envelopes. Its versatility across diverse application scenarios, backed by rigorous manufacturing standards and comprehensive support, positions it as an indispensable component for architects, designers, and engineers seeking to create future-proof, iconic structures. As demand for high-performance and visually striking building materials continues to grow, laminated metal mesh glass stands ready to define the next generation of architectural excellence.

References

- ASTM International. (2020). ASTM E1300/E1300M-16: Standard Practice for Determining Load Resistance of Glass in Buildings.

- International Organization for Standardization. (2019). ISO 12543-1: Glass in building – Laminated glass and laminated safety glass – Part 1: Definitions and description of component parts.

- US Green Building Council. (2023). LEED (Leadership in Energy and Environmental Design) v4.1 Building Design and Construction Reference Guide.

- The Glass Association of North America (GANA). (2017). GANA Glazing Manual.

- DuPont. (2018). SentryGlas® Interlayer Product Information.

This is the last article

-

Durable Metal Mesh Fabric For Glass Laminated | Strength & Style

NewsAug.23,2025

-

Hexagonal Wire Mesh: Durable Galvanized & PVC Coated Rolls

NewsAug.22,2025

-

Durable Hexagonal Gabions for Erosion Control & Retaining Walls

NewsAug.21,2025

-

Durable Hexagonal Gabion for Erosion Control & Retaining Walls

NewsAug.19,2025

-

Durable & Stylish Roof Tiles for Lasting Home Protection

NewsAug.18,2025

-

Secure & Stylish Fences for Garden, Pool & Property Needs

NewsAug.17,2025