-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Des . 09, 2024 15:10 Back to list

galvanized woven wire mesh factories

Understanding Galvanized Woven Wire Mesh Factories

In the world of industrial manufacturing, galvanized woven wire mesh has emerged as a vital product, serving diverse applications across various sectors. This article delves into the workings of galvanized woven wire mesh factories, highlighting their processes, applications, and significance in today’s market.

What is Galvanized Woven Wire Mesh?

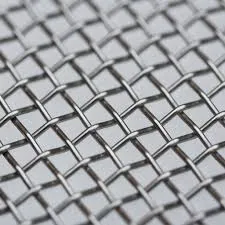

Galvanized woven wire mesh is a type of mesh made from steel wires that are woven together and then galvanized, a process that involves coating the wires with a layer of zinc to prevent rust and corrosion. This treatment enhances the durability and strength of the mesh, making it suitable for both indoor and outdoor applications. The resulting product is known for its resilience, flexibility, and aesthetic appeal.

The Manufacturing Process

The production of galvanized woven wire mesh involves several key steps

1. Wire Preparation The manufacturing process begins with the selection of high-quality steel wires. These wires are then drawn to the required thickness, which can vary depending on the intended use of the mesh.

2. Weaving Once the wires are prepared, they are woven on specialized machines. During this process, the wires are interlaced to form the mesh pattern. The most common weaving patterns include plain weave, twill weave, and Dutch weave, each offering different strengths and characteristics suitable for various applications.

3. Galvanization After weaving, the mesh undergoes galvanization. This can be carried out through two primary methods hot-dip galvanization, where the woven mesh is submerged in molten zinc, and electro-galvanization, where a thin layer of zinc is applied through an electrochemical process. Hot-dip galvanization typically provides a thicker and more durable coating, making it preferable for outdoor applications.

4. Cutting and Packaging Once galvanized, the mesh is cut into specific dimensions based on customer requirements. The finished products are then carefully packaged to prevent damage during transportation and storage.

Applications of Galvanized Woven Wire Mesh

galvanized woven wire mesh factories

Galvanized woven wire mesh is used in a myriad of applications across multiple industries

- Construction It is widely utilized in the construction sector for reinforcing concrete and as a barrier for fencing systems. Builders appreciate its strength and ability to withstand environmental conditions.

- Agriculture Farmers and agricultural professionals use galvanized wire mesh for fencing livestock and protecting crops. Its durability ensures long-term use in fields and pastures.

- Industrial Uses In industrial settings, this mesh is used for sieving, filtering, and even creating machine guards. Its corrosion resistance is particularly valuable in environments that may expose it to moisture and chemicals.

- Decorative Uses Interior designers and architects often utilize galvanized woven wire mesh in decorative applications, including room partitions, wall art, and furniture design. Its aesthetic versatility combined with durability makes it a popular choice.

The Importance of Quality

In a market flooded with various manufacturers, the quality of galvanized woven wire mesh can differ significantly. Buyers should prioritize sourcing from reputable factories that adhere to strict quality control measures. Factors such as wire gauge, mesh pattern, and galvanization quality play crucial roles in determining the mesh’s durability and performance. Factories that invest in advanced production techniques and regular testing will offer products that stand the test of time.

Environmental Considerations

With increasing awareness of environmental sustainability, many manufacturers are shifting towards eco-friendly practices. This includes using recyclable materials for packaging and adopting cleaner production processes that minimize waste. Companies that prioritize sustainability not only contribute to environmental preservation but also appeal to an increasingly conscientious consumer base.

Conclusion

Galvanized woven wire mesh factories play a pivotal role in supplying a highly versatile and durable product that has applications across various industries. Understanding the manufacturing process, the uses, and the importance of quality can empower businesses and consumers to make informed choices. As the demand for reliable and sustainable materials continues to rise, these factories will remain essential players in the manufacturing landscape, contributing to the growth and development of numerous sectors.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025