-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 05, 2024 02:38 Back to list

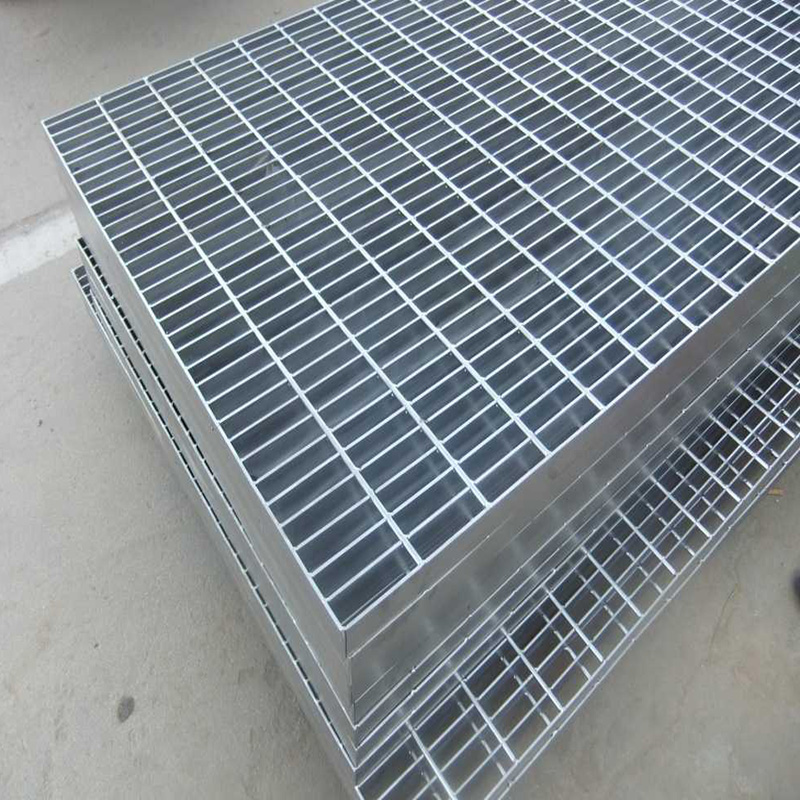

high quality wire mesh screen

High-Quality Wire Mesh Screens Essential for Versatile Applications

Wire mesh screens are integral components in various industries, providing essential functions ranging from filtration to safety. High-quality wire mesh screens are designed to meet specific needs, offering durability, precision, and versatility. In this article, we explore the importance of high-quality wire mesh screens, their applications, and the factors that contribute to their quality.

High-Quality Wire Mesh Screens Essential for Versatile Applications

The manufacturing process significantly influences the quality of wire mesh screens. Precision weaving techniques ensure that each screen has the appropriate mesh size and wire diameter, which directly affects its performance. Different weaving methods, such as plain weave, twill weave, or Dutch weave, provide varying degrees of strength and filtration capabilities. For instance, a Dutch weave may offer enhanced filtration for fine particles, making it ideal for industries such as pharmaceuticals and food processing.

high quality wire mesh screen

High-quality wire mesh screens are employed in a multitude of applications. In the construction industry, they are used in concrete reinforcement and as safety barriers. In the agricultural sector, wire mesh screens serve as pest control mechanisms, allowing airflow while preventing unwanted insects from entering crops. The automotive and aerospace industries utilize these screens for filtration systems, ensuring that impurities do not compromise engine performance. Additionally, wire mesh screens are crucial in environmental applications, such as water treatment and waste management, where they help in separating debris and contaminants from liquids.

Furthermore, the ease of maintenance and cleaning is an essential factor when considering high-quality wire mesh screens. Screens that are designed for easy removal and cleaning contribute to operational efficiency, boosting productivity in various settings. Industries that rely on continuous processes benefit significantly from screens that maintain their integrity and functionality over time, reducing downtime and maintenance costs.

In conclusion, high-quality wire mesh screens are vital in numerous industries, thanks to their durability, precision, and ease of use. As technology advances, the production of these screens continues to improve, catering to specific industry needs and ensuring optimal performance. When selecting wire mesh screens, it is crucial to consider the material, manufacturing process, and intended application to ensure that they meet the highest standards of quality and efficiency. Whether for industrial, agricultural, or environmental purposes, investing in high-quality wire mesh screens is a decision that pays dividends in reliability and performance.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025