-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 06, 2025 11:16 Back to list

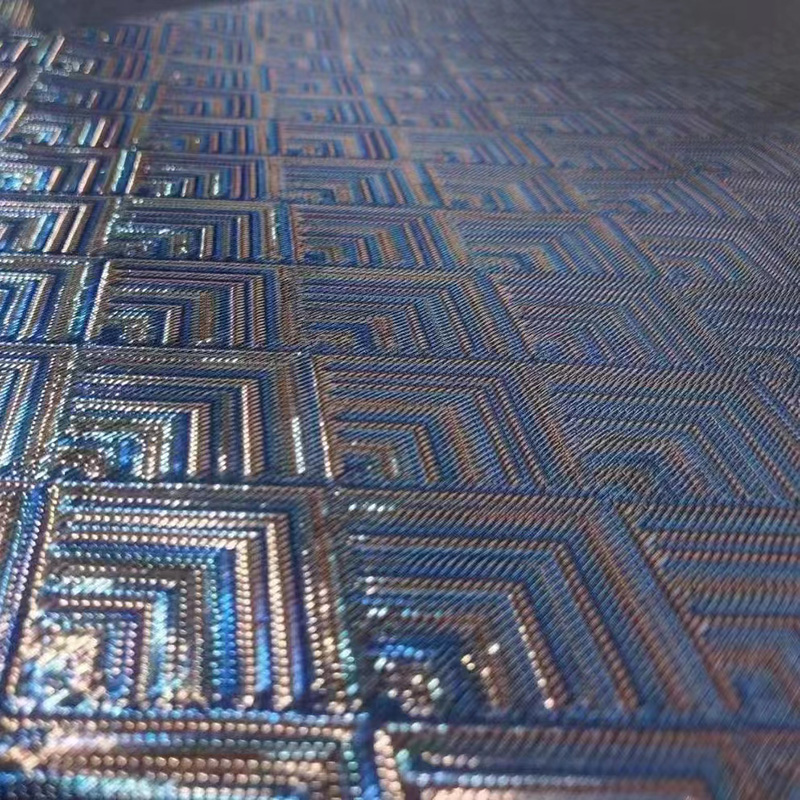

iron wire mesh

Iron wire mesh is an integral component in various industries, owing to its unique blend of strength, versatility, and cost-effectiveness. Its applications span construction, agriculture, art, and even home improvement, making it a product that demands a keen understanding of its properties and uses.

Experiencing the use of iron wire mesh unveils its unmatched adaptability. In construction, iron wire mesh serves as a reinforcement material, enhancing the tensile strength of concrete structures. Its grid-like design not only aids in distributing structural load evenly but also mitigates the chances of cracking, leading to buildings that withstand seismic activities better. Personal experiences from construction experts often highlight not just the mesh's durability but also its ease of installation, which reduces labor costs and accelerates project timelines, ensuring efficiency in large-scale developments.

Expertise in handling iron wire mesh is crucial, especially in specialized sectors like agriculture. Here, it functions as an effective enclosure solution for livestock and plants. The expertise lies in selecting the appropriate weave and wire gauge to match specific needs, such as keeping out certain predatory animals while ensuring ventilation and visibility. Agricultural specialists advocate for hot-dip galvanized iron wire mesh for its rust-resistant properties, ensuring that enclosures remain intact through varied weather conditions, thus securing crops and livestock reliably.

Authoritativeness in discussing iron wire mesh stems from a comprehensive understanding of its manufacturing process, strengths, and limitations. Primarily composed of low-carbon steel, the mesh undergoes a galvanization process to prevent corrosion, extending its service life significantly. This manufacturing detail is crucial for industry professionals who must adhere to stringent safety standards without compromising on longevity or effectiveness. An authoritative voice in this field often emphasizes compliance with international standards like ASTM or ISO to ensure both quality assurance and customer satisfaction.

Trustworthiness, in terms of using iron wire mesh, revolves around its proven track record and feedback from long-term users. Testimonials from engineers and architects frequently validate the mesh’s role in promoting structural integrity, while agricultural users vouch for its reliability in safeguarding assets. Potential users are encouraged to seek out products backed by reputable certifications and client endorsements. Trust also emerges through transparent communication from suppliers about the mesh’s features, proper handling, and maintenance practices, ensuring consumers are equipped with all necessary knowledge to maximize the mesh’s effectiveness.

In conclusion, iron wire mesh stands out as a product of remarkable importance across various domains due to its robustness and versatility. Understanding its applications from experienced users, selecting the right specifications from knowledgeable professionals, ensuring compliance with recognized standards, and relying on feedback from trusted sources are fundamental in leveraging the full potential of iron wire mesh. By focusing on these key aspects, businesses and individuals can make informed decisions, resulting in enhanced outcomes tailored to their specific needs.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025