-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Okt . 16, 2024 22:59 Back to list

Exporting Wire Mesh Solutions for Concrete Applications Worldwide

Wire Mesh for Concrete Exporter A Key Component in Construction

In the world of construction, the use of quality materials is paramount, ensuring the longevity and reliability of structures. One such essential material is wire mesh, often described as the backbone of concrete reinforcement. As urban development continues to expand globally, the demand for wire mesh for concrete has surged, leading to a thriving export market catering to this necessity.

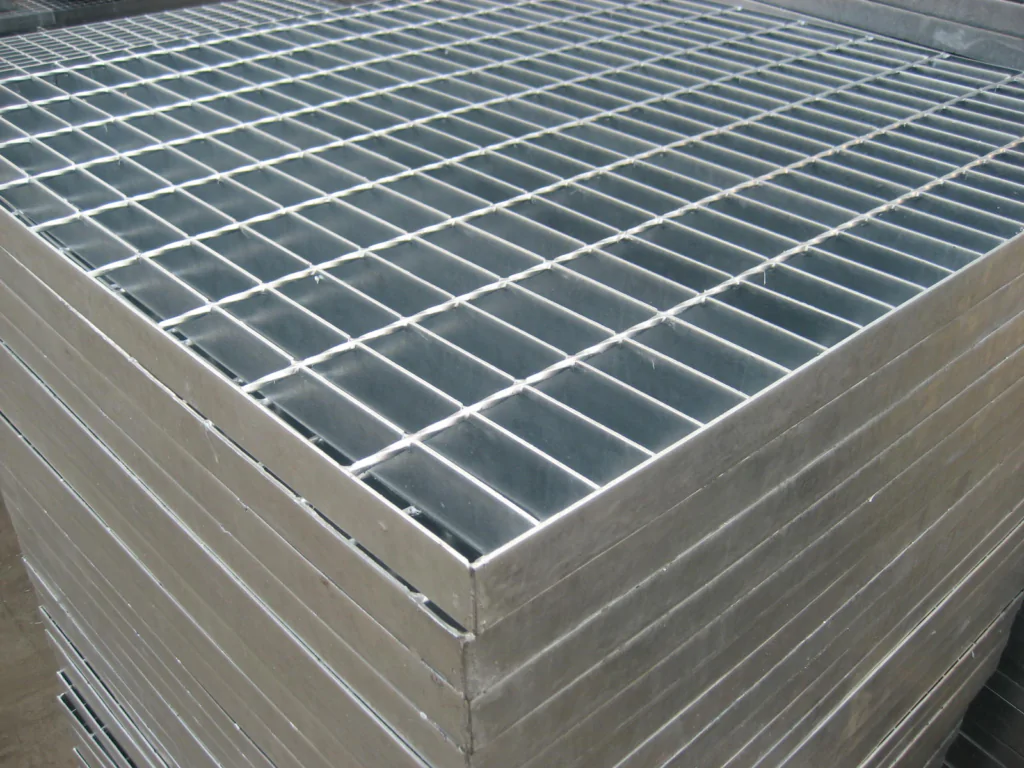

Wire mesh, specifically designed for use in concrete, serves as a matrix that strengthens and stabilizes the material. It helps control cracking by providing even support throughout the structure, enhancing the overall performance of concrete elements such as slabs, walls, and pavements. The mesh is typically made from high-quality steel wires that are woven or welded together to create a grid-like pattern. This process ensures optimal tensile strength and durability, which are crucial factors in construction projects facing various environmental stresses.

The Role of Exporters

Exporters play a vital role in bridging the gap between manufacturers and construction sectors across the globe. By sourcing high-quality wire mesh from established producers, they can offer a wide range of products tailored to meet specific regional and project requirements. This adaptability is particularly vital in a diverse market where construction practices, regulations, and environmental conditions may vary significantly.

Leading wire mesh exporters not only provide standard mesh options but also custom solutions to cater to specialized applications. These may include varying wire diameters, mesh sizes, coatings for corrosion resistance, and pre-fabrication options for easier installation on-site. This degree of customization ensures that every project receives the optimal reinforcement solution, ultimately improving construction efficiency and effectiveness.

wire mesh for concrete exporter

Quality Assurance and Compliance

For wire mesh to be effective in concrete applications, it must meet stringent quality standards. Reputable exporters conduct rigorous testing to ensure that their products comply with international construction codes and safety regulations. This includes evaluating factors such as tensile strength, weld integrity, and resistance to corrosion. By maintaining high standards, exporters safeguard their clients against potential structural failures or increased maintenance costs down the line.

Many exporters are also increasingly focusing on sustainable practices. With the construction industry acknowledging its environmental impact, the demand for eco-friendly materials is on the rise. Exporters are adapting by utilizing recycled steel for wire mesh production, minimizing waste, and reducing their carbon footprint. This commitment to sustainability not only meets regulatory demands but also aligns with the growing consumer preference for environmentally responsible building solutions.

Conclusion

As cities around the world continue to grow and evolve, the construction industry must adapt to meet these challenges. Wire mesh for concrete has emerged as an indispensable element in this landscape, and exporters are at the forefront of delivering quality, innovation, and sustainability. By understanding the critical role that wire mesh plays in concrete reinforcement and the benefits of sourcing from reputable exporters, construction professionals can ensure their projects stand the test of time. With the right materials and practices in place, the future of construction looks promising, paving the way for safer, more resilient structures in every corner of the globe.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025