-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Des . 09, 2024 14:31 Back to list

woven wire fence factories

The Evolution and Importance of Woven Wire Fence Factories

Woven wire fencing has long been a staple in agricultural and industrial applications, providing security, containment, and durability. The evolution of woven wire fence factories reflects significant advancements in manufacturing technology and design, addressing the diverse needs of various industries. This article delves into the intricate workings of woven wire fence factories, their significance in various sectors, and the trends shaping their future.

Historical Perspective

Historically, fencing was constructed using natural materials such as wood and stone. However, the introduction of woven wire fences in the late 19th century revolutionized the industry. Initially crafted by hand, these fences provided a cost-effective and durable alternative to traditional options. As demand grew, the need for specialized factories arose to streamline production and increase efficiency.

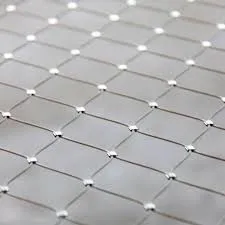

Woven wire fences became particularly popular in agriculture, where they served to contain livestock and protect crops from predators. The design typically features a series of vertical and horizontal wires that are woven together, providing both strength and flexibility. Over time, these factories began to develop various types of woven wire fences suitable for different applications, including barbed wire for added security and high-tensile fencing for enhanced durability.

Manufacturing Process

The manufacturing of woven wire fences involves several stages, starting with the selection of raw materials. Factories typically use high-quality steel wire, which is drawn down to the required gauge to ensure strength and resilience. This wire is then twisted and woven into various patterns, depending on the type of fence being produced. Advanced machinery plays a crucial role in this process, allowing for high-speed production while maintaining precise specifications.

Additionally, factories employ various protective coatings, such as galvanization, to enhance the longevity of the fence. This process involves coating the wire with a layer of zinc to prevent rust and corrosion, thereby increasing the lifespan of the fencing material. The final stage involves cutting, rolling, and packaging the fences for distribution to wholesalers and retailers.

woven wire fence factories

Importance Across Industries

Woven wire fences are not just a necessity in agriculture; they have far-reaching applications across multiple sectors. In construction, they are used for security purposes, protecting sites and valuable materials from theft or vandalism. In the transportation sector, woven wire fencing is often used to delineate boundaries, ensuring public safety and controlling access to roadways and airports.

Moreover, these fences are utilized in various recreational areas, such as parks and sports facilities, creating safe environments while allowing visibility. Their versatility makes them an essential product in both rural and urban settings.

Trends Shaping the Future

Recent trends suggest a shift towards more sustainable manufacturing practices within woven wire fence factories. The growing emphasis on eco-friendly products has led to the exploration of recycled materials and more efficient processes that reduce waste and energy consumption. Embracing sustainability not only meets consumer demand but also aligns with global efforts to combat environmental challenges.

Furthermore, technological advancements such as automation and the Internet of Things (IoT) are set to revolutionize the manufacturing process. Smart factories equipped with connected devices can monitor production in real-time, optimize efficiency, and reduce operational costs. This shift towards smart manufacturing will enable woven wire fence factories to respond quickly to market demands while maintaining high quality.

Conclusion

Woven wire fence factories play a vital role in meeting the fencing needs of various industries, from agriculture to construction. Their evolution reflects technological advancements and changing market demands, ensuring that they remain relevant in today’s fast-paced world. As the industry continues to embrace sustainability and automation, the future of woven wire fencing looks promising, poised to adapt and thrive in a dynamic environment. Whether for enclosing livestock or enhancing security, woven wire fences are set to remain an integral part of infrastructure worldwide.

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025