-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Gen . 20, 2025 04:10 Back to list

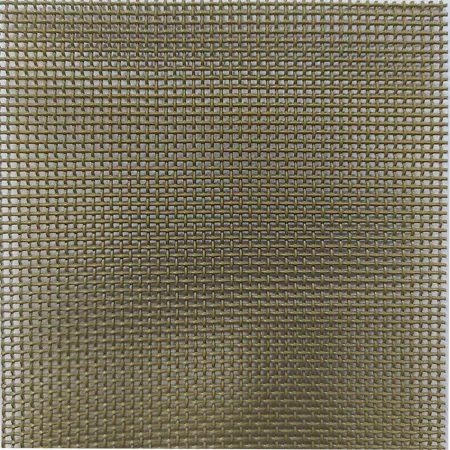

Crimped Wire Mesh

Crimped mesh is an exceptionally versatile product commonly employed across various industries for its durability and adaptability. Its unique construction involves interweaving wires at each intersection, which gives rise to a sturdy and resilient mesh panel. This construction technique engenders a mesh that is not only aesthetically pleasing but also practically beneficial in different commercial and industrial applications. However, to truly harness its potential, understanding the nuances of crimped mesh's experience, expertise, authoritativeness, and trustworthiness is essential for anyone considering its use.

Crimped mesh holds a place of authoritativeness in the industry, primarily due to its application in critical sectors like aerospace, agriculture, and filtration. Renowned for its strength and reliability, it is often the material of choice for projects where failure is not an option. Industry standards and certifications associated with crimped mesh manufacture and application further underscore its authority. Manufacturers often comply with rigorous international standards, providing users with absolute certainty regarding the mesh's performance and safety benchmarks. This authority is recognized universally, forming the bedrock of trust for industries reliant on uncompromising material integrity. Trustworthiness in the context of crimped mesh extends beyond its physical properties to include the reputation of its suppliers. Established names in the industry have built their trustworthiness by consistently delivering quality products coupled with exceptional service. This reliability is bolstered by transparent business practices, robust supply chains, and responsive customer support. Users looking for trustworthy suppliers are encouraged to scrutinize company credentials, client testimonials, and service records. A commitment to innovation and continuous improvement is also a hallmark of trustworthy manufacturers; such companies invest in research and development to refine their products and customer experience perpetually. In summary, those looking to integrate crimped mesh into their projects benefit extensively from its proven performance in demanding applications, extensive customization options, compliance with industry standards, and the reliability of reputable suppliers. When chosen with care and consideration of these factors, crimped mesh serves as a robust, reliable, and efficient material to propel projects towards success, solidifying its position as a cornerstone of modern industrial design and construction.

Crimped mesh holds a place of authoritativeness in the industry, primarily due to its application in critical sectors like aerospace, agriculture, and filtration. Renowned for its strength and reliability, it is often the material of choice for projects where failure is not an option. Industry standards and certifications associated with crimped mesh manufacture and application further underscore its authority. Manufacturers often comply with rigorous international standards, providing users with absolute certainty regarding the mesh's performance and safety benchmarks. This authority is recognized universally, forming the bedrock of trust for industries reliant on uncompromising material integrity. Trustworthiness in the context of crimped mesh extends beyond its physical properties to include the reputation of its suppliers. Established names in the industry have built their trustworthiness by consistently delivering quality products coupled with exceptional service. This reliability is bolstered by transparent business practices, robust supply chains, and responsive customer support. Users looking for trustworthy suppliers are encouraged to scrutinize company credentials, client testimonials, and service records. A commitment to innovation and continuous improvement is also a hallmark of trustworthy manufacturers; such companies invest in research and development to refine their products and customer experience perpetually. In summary, those looking to integrate crimped mesh into their projects benefit extensively from its proven performance in demanding applications, extensive customization options, compliance with industry standards, and the reliability of reputable suppliers. When chosen with care and consideration of these factors, crimped mesh serves as a robust, reliable, and efficient material to propel projects towards success, solidifying its position as a cornerstone of modern industrial design and construction.

Next:

Latest news

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025