-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 14, 2025 04:25 Back to list

custom hexagonal wire mesh

When considering the purchase or application of custom galvanized wire, specifically in the 3mm diameter range, it's crucial to understand the multifaceted benefits and pivotal role this product plays across diverse industries. Not only is it a staple in various applications, but it also underscores the intersection of material science and practical utility.

While technical specifications and industry applications are critical, understanding the expertise that goes into the selection and implementation of custom galvanized wire is equally important. Professionals in metallurgical science and production engineering emphasize the significance of proper galvanization methods to achieve the desired thickness of zinc coating, which determines the wire's endurance and resistance capabilities. Furthermore, choosing the right supplier for custom 3mm galvanized wire is vital to ensure quality and reliability. Reputable suppliers are known for their commitment to rigorous quality checks and compliance with international standards, providing customers with not just products, but solutions that can withstand the test of time and environmental challenges. When discussing custom 3mm galvanized wire, it’s imperative to consider the environmental and safety aspects associated with its use. Galvanized wire manufacturing should adhere to ecological best practices to minimize environmental impact. This involves using sustainable zinc sourcing and employing methods that reduce waste and emissions during the galvanizing process. Moreover, safety during handling and installation is paramount, thus requiring adequate training and compliance with safety standards to prevent workplace accidents. To summarize, the selection and application of custom 3mm galvanized wire should be approached with an understanding of not only its material benefits but also the depth of expertise required to maximize its potential. Expert insights from industry professionals should guide decisions to ensure that the wire chosen aligns with specific project needs and environmental conditions. By leveraging the knowledge and authority of seasoned experts in the field, businesses can make informed decisions that not only enhance operational efficiencies but also contribute to sustainable and safe practices. This informed approach ensures that the investment in custom galvanized wire pays off in terms of durability, cost efficiency, and environmental responsibility, representing a critical element in the ongoing narrative of material science and engineering excellence.

While technical specifications and industry applications are critical, understanding the expertise that goes into the selection and implementation of custom galvanized wire is equally important. Professionals in metallurgical science and production engineering emphasize the significance of proper galvanization methods to achieve the desired thickness of zinc coating, which determines the wire's endurance and resistance capabilities. Furthermore, choosing the right supplier for custom 3mm galvanized wire is vital to ensure quality and reliability. Reputable suppliers are known for their commitment to rigorous quality checks and compliance with international standards, providing customers with not just products, but solutions that can withstand the test of time and environmental challenges. When discussing custom 3mm galvanized wire, it’s imperative to consider the environmental and safety aspects associated with its use. Galvanized wire manufacturing should adhere to ecological best practices to minimize environmental impact. This involves using sustainable zinc sourcing and employing methods that reduce waste and emissions during the galvanizing process. Moreover, safety during handling and installation is paramount, thus requiring adequate training and compliance with safety standards to prevent workplace accidents. To summarize, the selection and application of custom 3mm galvanized wire should be approached with an understanding of not only its material benefits but also the depth of expertise required to maximize its potential. Expert insights from industry professionals should guide decisions to ensure that the wire chosen aligns with specific project needs and environmental conditions. By leveraging the knowledge and authority of seasoned experts in the field, businesses can make informed decisions that not only enhance operational efficiencies but also contribute to sustainable and safe practices. This informed approach ensures that the investment in custom galvanized wire pays off in terms of durability, cost efficiency, and environmental responsibility, representing a critical element in the ongoing narrative of material science and engineering excellence.

Latest news

-

Custom Crimped Wire Mesh | High Quality & Wholesale Supply

NewsAug.11,2025

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

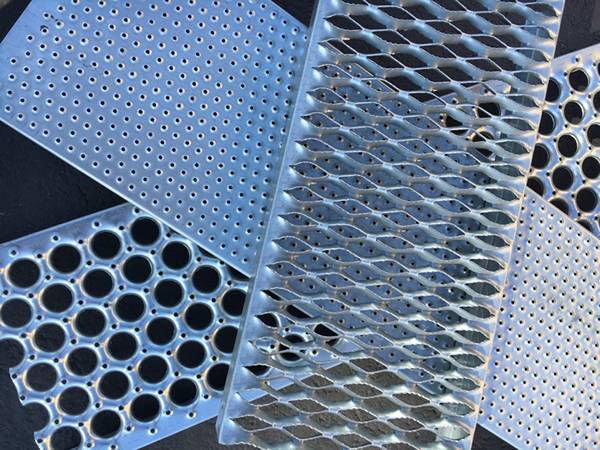

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025