-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 26, 2024 09:14 Back to list

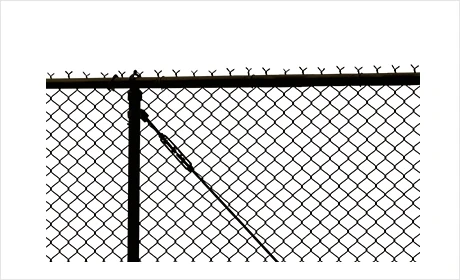

custom heavy duty wire mesh screens

Custom Heavy Duty Wire Mesh Screens Strength and Versatility for Various Applications

In today’s industrial landscape, the demand for robust and reliable materials is on the rise. One of the most versatile products that can be tailored to meet specific requirements is custom heavy duty wire mesh screens. These screens are essential in various applications, from construction and mining to food processing and agriculture. Their ability to endure extreme conditions while providing excellent filtration and separation makes them invaluable in multiple industries.

Understanding Wire Mesh Screens

Wire mesh screens are fabricated from wires that are woven together to form a grid-like pattern. The term heavy duty refers to the thicker gauge wire used in their production, resulting in increased strength and durability. Custom heavy duty wire mesh screens can be produced in different materials, including stainless steel, carbon steel, and aluminum, each offering unique benefits based on the environment in which they will be used.

Applications of Heavy Duty Wire Mesh Screens

1. Construction and Mining In construction and mining operations, durable wire mesh screens are vital for sorting and filtering materials. They are used to separate large rocks from finer materials or to create barriers at job sites. Their robust construction allows them to withstand heavy loads, making them ideal for rugged environments.

2. Agriculture Farmers and agricultural businesses use heavy duty wire mesh screens for various purposes, including fencing livestock, sorting seeds, and filtering water. Their customizability allows for specific mesh sizes, ensuring that they meet regulatory requirements and protect crops effectively.

3. Food Processing In the food industry, hygiene and safety are paramount. Stainless steel heavy duty wire mesh screens are frequently used for sanitation purposes, as they are resistant to corrosion and easy to clean. These screens can be used in sieving flour, straining liquids, and even in baking processes, where uniformity is key.

4. Waste Management Heavy duty wire mesh screens are also employed in waste management facilities, assisting in sorting recyclable materials and preventing unwanted debris from contaminating clean waste streams. Their ability to handle heavy loads ensures that they remain functional in high-pressure environments.

custom heavy duty wire mesh screens

Customization for Specific Needs

One of the most significant advantages of heavy duty wire mesh screens is their ability to be customized. Manufacturers can tailor the specifications to meet client needs, including

- Material Type Depending on the application, clients can choose from a variety of materials to best suit the environment where the screens will be used. - Mesh Size The size of the openings in the wire mesh can be adjusted according to the intended use, ensuring optimal performance for filtering or screening purposes.

- Frame and Support Custom frames and supports can be designed to enhance the stability of the screens, providing added strength where required.

- Finish Different finishes can be applied to increase resistance against corrosion and wear, extending the lifespan of the screens in harsh environments.

Importance of Quality and Reliability

When it comes to custom heavy duty wire mesh screens, the quality of materials and manufacturing processes is crucial. High-quality wire mesh ensures durability, reducing the need for frequent replacements and maintenance. Companies that invest in reliable wire mesh also benefit from increased operational efficiencies, as these screens will perform consistently over time, contributing to overall productivity.

Conclusion

Custom heavy duty wire mesh screens are a quintessential element in many industries, providing essential solutions for filtering, sorting, and protecting various materials. Their adaptability in terms of material, design, and application makes them a preferred choice for businesses looking to enhance their operations. As industries increasingly prioritize efficiency and reliability, the demand for such tailored solutions will only continue to grow, solidifying the role of custom heavy duty wire mesh screens in the modern marketplace. Whether for industrial, agricultural, or food-related applications, investing in quality wire mesh is a decision that yields significant long-term benefits for businesses across sectors.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025