-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 03, 2025 03:17 Back to list

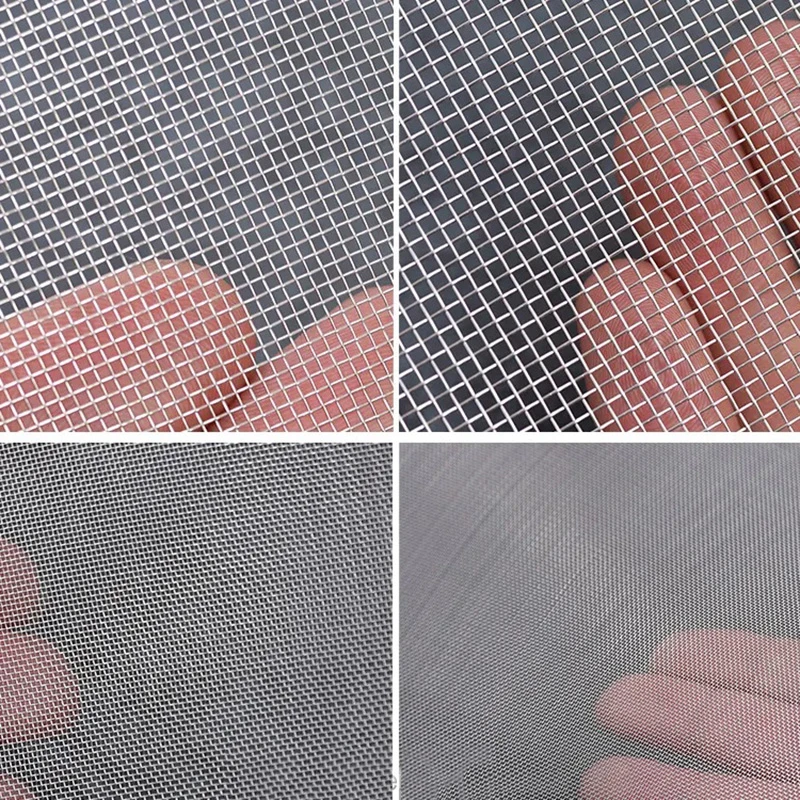

custom perforated metal mesh

Custom steel matting has emerged as a transformative material in various sectors, including construction, automotive, and design. Its unique properties and versatility make it a preferred choice for professionals who require durable and customizable solutions. In this exploration of custom steel matting, we delve into the experiential, expert, authoritative, and trustworthy facets that define this material's application in modern industry.

Trustworthiness is a crucial consideration for clients investing in custom steel matting. Reputable suppliers and manufacturers underline their commitment to quality through certifications and endorsements from recognized bodies. Testimonials from industry professionals and documented case studies attest to the material's performance in real-world scenarios. Trust is further cemented by transparent communication regarding the manufacturing process, material sourcing, and environmental impact, aligning with sustainable development goals. Beyond its traditional uses, custom steel matting is increasingly appreciated in creative industries. Interior designers employ it as a stylish solution for modern and industrial-themed decor, using it for partitions, shelving, and accent walls. Its minimalist aesthetic complements contemporary design trends while retaining functionality. The flexibility in design customization allows designers to adapt the material for bespoke projects, underscoring its growing versatility. For automotive applications, custom steel matting serves as a protective guard for vehicles, particularly in off-road conditions. Its strength safeguards vulnerable parts from debris and enhances safety for occupants. Custom configurations ensure that the matting precisely fits the vehicle's framework, optimizing both protection and aesthetics. As a sustainable building material, custom steel matting is made from recyclable steel, contributing to eco-friendly construction practices. Its durability reduces the need for frequent replacement, minimizing waste and resource consumption. Forward-thinking companies are exploring the integration of recycled materials in producing steel matting, further decreasing environmental impact while maintaining high standards of quality. In conclusion, the multifaceted nature of custom steel matting positions it as a cornerstone material in both traditional and innovative applications. Through its experiential benefits, expert-backed functionality, authoritative support through industry standards, and trustworthy performance, it continues to be an invaluable resource. As industries evolve, the customization potential and adaptability of steel matting will undoubtedly unlock new opportunities for its utilization, catalyzing advancements across various domains.

Trustworthiness is a crucial consideration for clients investing in custom steel matting. Reputable suppliers and manufacturers underline their commitment to quality through certifications and endorsements from recognized bodies. Testimonials from industry professionals and documented case studies attest to the material's performance in real-world scenarios. Trust is further cemented by transparent communication regarding the manufacturing process, material sourcing, and environmental impact, aligning with sustainable development goals. Beyond its traditional uses, custom steel matting is increasingly appreciated in creative industries. Interior designers employ it as a stylish solution for modern and industrial-themed decor, using it for partitions, shelving, and accent walls. Its minimalist aesthetic complements contemporary design trends while retaining functionality. The flexibility in design customization allows designers to adapt the material for bespoke projects, underscoring its growing versatility. For automotive applications, custom steel matting serves as a protective guard for vehicles, particularly in off-road conditions. Its strength safeguards vulnerable parts from debris and enhances safety for occupants. Custom configurations ensure that the matting precisely fits the vehicle's framework, optimizing both protection and aesthetics. As a sustainable building material, custom steel matting is made from recyclable steel, contributing to eco-friendly construction practices. Its durability reduces the need for frequent replacement, minimizing waste and resource consumption. Forward-thinking companies are exploring the integration of recycled materials in producing steel matting, further decreasing environmental impact while maintaining high standards of quality. In conclusion, the multifaceted nature of custom steel matting positions it as a cornerstone material in both traditional and innovative applications. Through its experiential benefits, expert-backed functionality, authoritative support through industry standards, and trustworthy performance, it continues to be an invaluable resource. As industries evolve, the customization potential and adaptability of steel matting will undoubtedly unlock new opportunities for its utilization, catalyzing advancements across various domains.

Latest news

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025