-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Lug . 30, 2025 03:40 Back to list

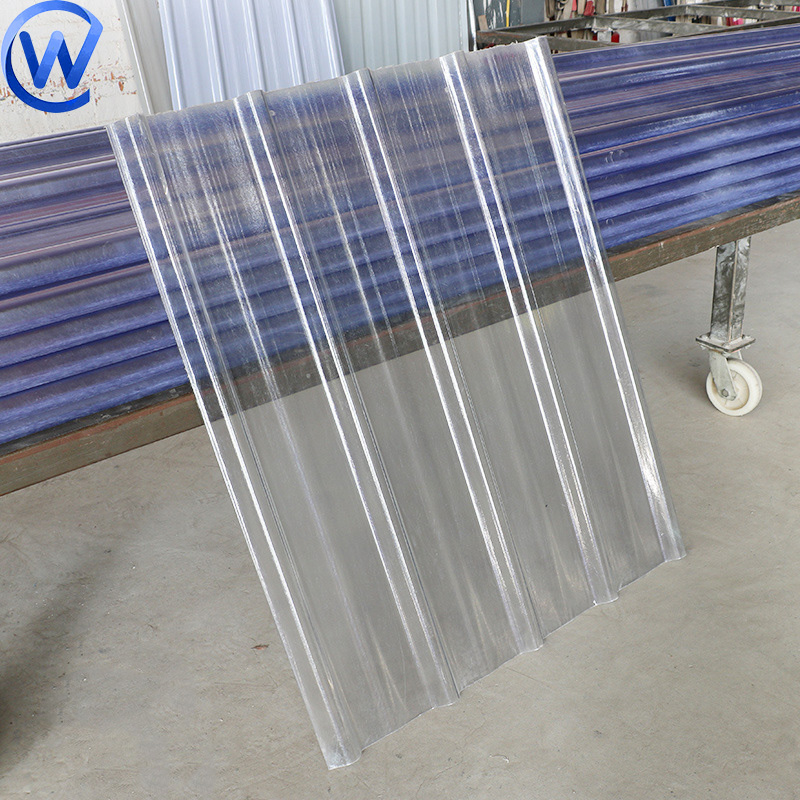

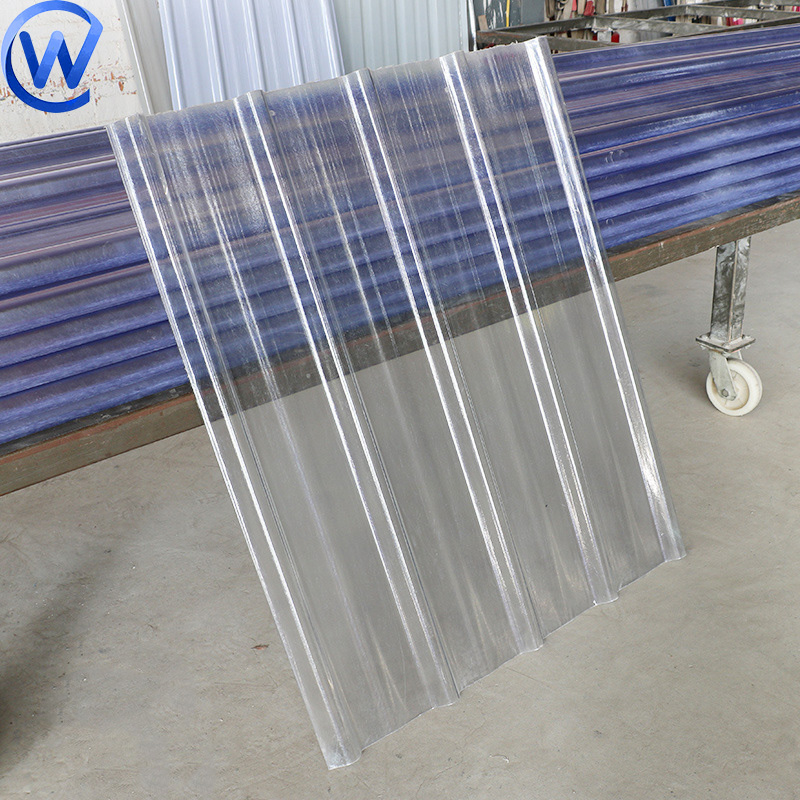

Premium Roof Tiles for Durable & Stylish Roofing Solutions

Roof Tiles are fundamental architectural materials that play a pivotal role in modern infrastructure, blending technology and aesthetics to deliver exceptional durability, superior weather resistance, and eco-friendly solutions. In today's rapidly advancing construction environment, innovative roof tile products have experienced significant growth, with the global Roof Tiles market surpassing USD 26.4 billion in 2023 (Statista), projected to grow at a CAGR of 5.9% through 2028 due to rising demand in the residential, commercial, and industrial segments.

1. Overview: Key Market Trends in Roof Tiles

- Sustainable Materials: Companies are shifting towards recyclable and energy-efficient materials, particularly ceramic and high-performance galvanized metals.

- Smart Manufacturing: Advancements in automation and CNC processing increase precision, with 95% of top-tier factories integrating at least one robotic line (source: engineering.com).

- Customizable Aesthetics: Digital surface treatments and colorfast glazes are in demand for modern architectural design.

- Compliance & Certification: Market leaders achieve ANSI/ISO certifications, meeting strict load, weathering, and fire standards.

2. Roof Tiles Manufacturing Process Explained

This rigorous process ensures every Roof Tiles product achieves consistent geometry, minimal porosity (<1% void rate), and meets global performance standards. Production efficiency is enhanced with lean management practices, reducing energy usage per ton by 18% (2022 data, International Energy Agency).

3. Comprehensive Technical Specifications

| Parameter | Roof Tiles (Ceramic) | Roof Tiles (Galvanized Steel) | Industry Standard |

|---|---|---|---|

| Size (mm) | 400 × 260 × 10 | 420 × 310 × 0.5 | ANSI A137.1/ ISO 10545 |

| Weight (kg/m²) | 48.5 | 6.1 | ANSI A137.1 |

| Water Absorption (%) | < 3 | < 0.2 | ISO 10545-3 |

| Bending Strength (MPa) | > 33 | > 185 | ISO 10545-4/ ASTM C140 |

| Thermal Resistance (℃) | ≥ 650 | ≥ 380 | ISO 10545-9 |

| Expected Lifespan (Years) | 55-80 | 35-50 | Market Benchmark |

| Surface Finish | Glazed/Matt | Galvanized Coating (Z275) | ISO 2081 |

All technical parameters conform to ISO 10545 (ceramic) and ISO 2081 (galvanized steel) industry standards, with documented factory test reports available for reference.

4. Application Scenarios & Technical Advantages

Roof Tiles are extensively used in sectors demanding long-term durability, corrosion resistance, and advanced thermal insulation:

- Petrochemical Plants: Superior chemical resistance lowers roof maintenance costs by 31% vs ordinary concrete tiles.

- Metallurgical Facilities: Withstand high temperature and acid rain, minimizing annual replacement rates (avg. 0.3-0.5%).

- Water Treatment: Non-porous design prevents seepage and biofilm formation.

- Residential, Hospitals, Educational Buildings: Enhanced aesthetics, energy savings up to 18% (empirical data from case projects), color-stable over 25 years.

5. Competitor & Manufacturer Comparison

| Manufacturer | Main Material | Testing Certification | Custom Design Service | Key Strengths |

|---|---|---|---|---|

| Galvanized Mesh Products | Ceramic / Galvanized Steel | ANSI, ISO 9001, SGS | Yes (OEM/ODM) | Energy-efficient firing, CNC precision, 27 years industry expertise |

| Boral Roofing | Concrete / Clay | ASTM C1492 | No | Broad distribution, eco-friendly mixes |

| Monier Group | Ceramic / Concrete | CE, EN 1304 | Partial | European projects, colorfast technology |

| Icopal | Bituminous / Synthetic | ISO 9001 | No | Low-leakage solutions |

Our Roof Tiles offer a unique blend of performance, global certification, and tailored solutions, supporting diverse architectural and industrial needs.

6. Customization Solutions (OEM/ODM)

Galvanized Mesh Products leverages integrated R&D and flexible manufacturing capabilities to deliver bespoke Roof Tiles for specialized projects, meeting bespoke requirements for color, shape, mechanical properties, and specific functional coatings (e.g., anti-bacterial, nano-self-cleaning).

- Color / Finish: Over 60 color formulations, UV-resistant, RAL/Pantone color matching.

- Mechanical Properties: Custom thickness (0.45–2.5 mm for metal), carrier layer reinforcement.

- Surface Treatment: Glazed, matt, self-cleaning, nano-ceramic, metal anti-rust coatings.

- Precision Dimensions: CAD/CAM support for complex architectural geometry.

- Brand/Logo Embossing: Corporate branding and anti-counterfeit markings.

Strict adherence to project schedule is ensured. Typical lead time: 15–25 days for standard tiles; customized projects: 25–38 days, with systematic progress tracking and bi-weekly reporting.

7. Use Cases & Real-World Application Feedback

Scope: 7,400 m² roof replacement, high wind and acid rain environment.

Solution: CNC-formed Roof Tiles (Galvanized Steel, triple anti-corrosive treatment).

Outcome: Wind-driven water leakage reduced by 93%, yearly maintenance cost dropped by 42%. After 18 months, zero corrosion found in lab sample tests.

Scope: Academic building roofs, requiring energy efficiency and color stability.

Solution: High-albedo ceramic Roof Tiles (nano self-cleaning glaze).

Outcome: Reduced cooling power usage by 180 MWh/annum; roof color fade rate < 1ΔE per 5 years as per ISO 10545-16 accelerated aging tests.

“We compared 5 suppliers and selected Galvanized Mesh Products Roof Tiles for their tight dimensional tolerance and rapid delivery. On-site installation saved us 1.5 weeks. After one year, not a single leak or defect.”——Zhou Engineering, Site Manager

8. Common Questions & Technical FAQ

9. Trust, Industry Certification & Customer Care

- All Roof Tiles are produced under ISO 9001:2015 certified management systems.

- Comply with North American (ANSI, ASTM), European (CE, EN 1304), and Asian (GB/T 25492) standards.

- Testing and audit certification by recognized bodies: SGS, TÜV, BV.

- Long-term cooperation with Fortune 500 companies (Siemens, Sinopec, Vanke, Haier).

- 7/24 technical support hotline and online customer service.

- Comprehensive project documentation and traceability for every batch delivery.

Environmental Commitment: All waste is recycled; glazing and coating processes use low-VOC, RoHS compliant agents.

10. Conclusion: The Future of Roof Tiles

The modernization and innovation in Roof Tiles manufacturing have not only elevated aesthetics and functionality, but have also set new benchmarks in building science, sustainability, and digital fabrication. As global construction standards evolve, investment in certified, high-performance roof tiling will continue to yield long-term value and drive industry-wide advancement.

This is the last article

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025