-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Set . 07, 2024 10:40 Back to list

Wire Netting Factory - High-Quality Wire Mesh Solutions

Wire Netting Factory Crafting Durability and Versatility

In the modern manufacturing landscape, the wire netting factory plays a crucial role, producing an array of essential products that cater to various industries. Wire netting, known for its durability and versatility, finds applications in agriculture, construction, security, and more. This article explores the processes, products, and significance of wire netting factories in today’s economy.

At its core, a wire netting factory transforms raw materials into functional and robust wire mesh products. The manufacturing process typically begins with sourcing high-quality wire, which can be made from various materials such as stainless steel, galvanized steel, or plastic-coated wire. The choice of material plays a significant role in the eventual application of the wire netting. For instance, galvanized wire offers excellent rust resistance, making it ideal for outdoor use, while stainless steel provides enhanced durability and aesthetic appeal.

Once the materials are procured, the manufacturing process proceeds to several essential steps, including wire drawing, weaving, and finishing. Wire drawing entails pulling the raw wire through a series of dies to reduce its diameter and increase its tensile strength. This process ensures that the wire meets the specific requirements of mesh size and thickness for different applications.

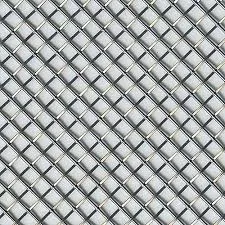

Weaving is the next pivotal phase, where the drawn wire is transformed into a mesh structure. Various weaving techniques, such as square, hexagonal, or welded mesh, are employed in this stage. The choice of weave depends on the intended use of the netting. For example, hexagonal wire netting is commonly used in poultry fencing and garden enclosures, while welded wire mesh provides added strength, making it suitable for concrete reinforcement and industrial applications.

wire netting factory

After weaving, the wire netting undergoes a finishing process, which may involve galvanization, powder coating, or other treatments. This step not only enhances the aesthetic appeal of the wire mesh products but also increases their resistance to corrosion, weathering, and UV damage. The result is a versatile product that can withstand various environmental conditions.

The applications for wire netting are vast and varied, making it an indispensable component in multiple sectors. In agriculture, wire netting is used to create fences for livestock, protect crops from animals, and even support plant growth as trellises. In construction, it provides structural support for concrete and masonry projects, while also serving as safety barriers on construction sites. Additionally, the security sector relies on wire netting for fencing solutions to protect properties and provide a sense of safety.

Moreover, the wire netting factory contributes significantly to local economies by providing employment opportunities and supporting related industries. As demand for wire netting products continues to grow, factories are increasingly adopting modern technologies and automation to enhance efficiency and reduce costs. This evolution in manufacturing not only meets consumer needs but also aligns with sustainability goals by minimizing waste and energy consumption.

In conclusion, wire netting factories are integral to producing versatile products that serve essential roles in various industries. From agriculture to construction and security, the applications of wire netting are vast, underscoring its importance in our daily lives. As these factories continue to innovate and adapt to changing market demands, they will undoubtedly remain a key player in the industrial landscape, providing durable, reliable, and efficient wire mesh solutions for years to come.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025