-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Feb . 15, 2025 12:36 Back to list

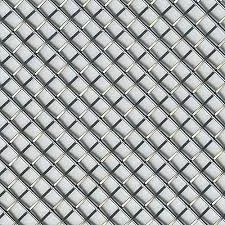

custom hexagonal wire mesh

Custom hot dipped galvanized wire stands at the confluence of durability and practicality, serving as a vital material across a myriad of industries. Its comprehensive utility is driven by an amalgamation of its manufacturing process, properties, and application versatility, which collectively make it an indispensable product for numerous projects. The value of this wire is deeply rooted in its ability to meet stringent quality standards while providing long-lasting performance.

Trustworthiness in delivering consistent quality can only be established through stringent quality assurance protocols. These protocols encompass rigorous testing phases where each batch of wire is subjected to a series of evaluations, such as determining its resistance to environmental factors, its mechanical flexibility, and its adherence capacity. By adhering to international standards and certifications, manufacturers gain the trust of the industries they serve, guaranteeing that the wire will perform reliably. The experience shared by industry veterans illustrates the transformative impact of custom hot dipped galvanized wire across different sectors. From supporting the skeletal framework of towering skyscrapers to protecting vineyards with durable fencing, its applications are boundless. Farmers, who often face the brunt of nature’s unpredictability, rely on galvanized wire for its unparalleled anti-corrosive properties, ensuring that their boundaries remain intact season after season. Innovation continues to drive the evolution of this product, with advancements in coating technology and adaptive manufacturing processes addressing ever-evolving industry requirements. Engineers are continually researching enhanced alloys and coatings that can extend the lifespan and efficiency of the wire even further, ensuring that this material remains at the forefront of industrial needs long into the future. Selecting custom hot dipped galvanized wire isn't just about purchasing a product; it’s about forging a partnership grounded in quality, reliability, and innovation. Clients can rest assured that they’re investing in a product backed by a legacy of industry expertise and a forward-thinking approach to solving modern-day challenges. It is this comprehensive understanding and commitment to excellence that sets the standard for custom hot dipped galvanized wire, cementing its reputation as a top-tier product in the global market.

Trustworthiness in delivering consistent quality can only be established through stringent quality assurance protocols. These protocols encompass rigorous testing phases where each batch of wire is subjected to a series of evaluations, such as determining its resistance to environmental factors, its mechanical flexibility, and its adherence capacity. By adhering to international standards and certifications, manufacturers gain the trust of the industries they serve, guaranteeing that the wire will perform reliably. The experience shared by industry veterans illustrates the transformative impact of custom hot dipped galvanized wire across different sectors. From supporting the skeletal framework of towering skyscrapers to protecting vineyards with durable fencing, its applications are boundless. Farmers, who often face the brunt of nature’s unpredictability, rely on galvanized wire for its unparalleled anti-corrosive properties, ensuring that their boundaries remain intact season after season. Innovation continues to drive the evolution of this product, with advancements in coating technology and adaptive manufacturing processes addressing ever-evolving industry requirements. Engineers are continually researching enhanced alloys and coatings that can extend the lifespan and efficiency of the wire even further, ensuring that this material remains at the forefront of industrial needs long into the future. Selecting custom hot dipped galvanized wire isn't just about purchasing a product; it’s about forging a partnership grounded in quality, reliability, and innovation. Clients can rest assured that they’re investing in a product backed by a legacy of industry expertise and a forward-thinking approach to solving modern-day challenges. It is this comprehensive understanding and commitment to excellence that sets the standard for custom hot dipped galvanized wire, cementing its reputation as a top-tier product in the global market.

Latest news

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025